Rotary air lock feeding valve

A feeding valve and rotary feeding technology, applied in grain processing and other directions, can solve the problems of increasing the wear of the drive shaft, increasing the load of the whole machine, abnormal noise of the drive shaft, etc., so as to achieve reliable operation, high rigidity and strength, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

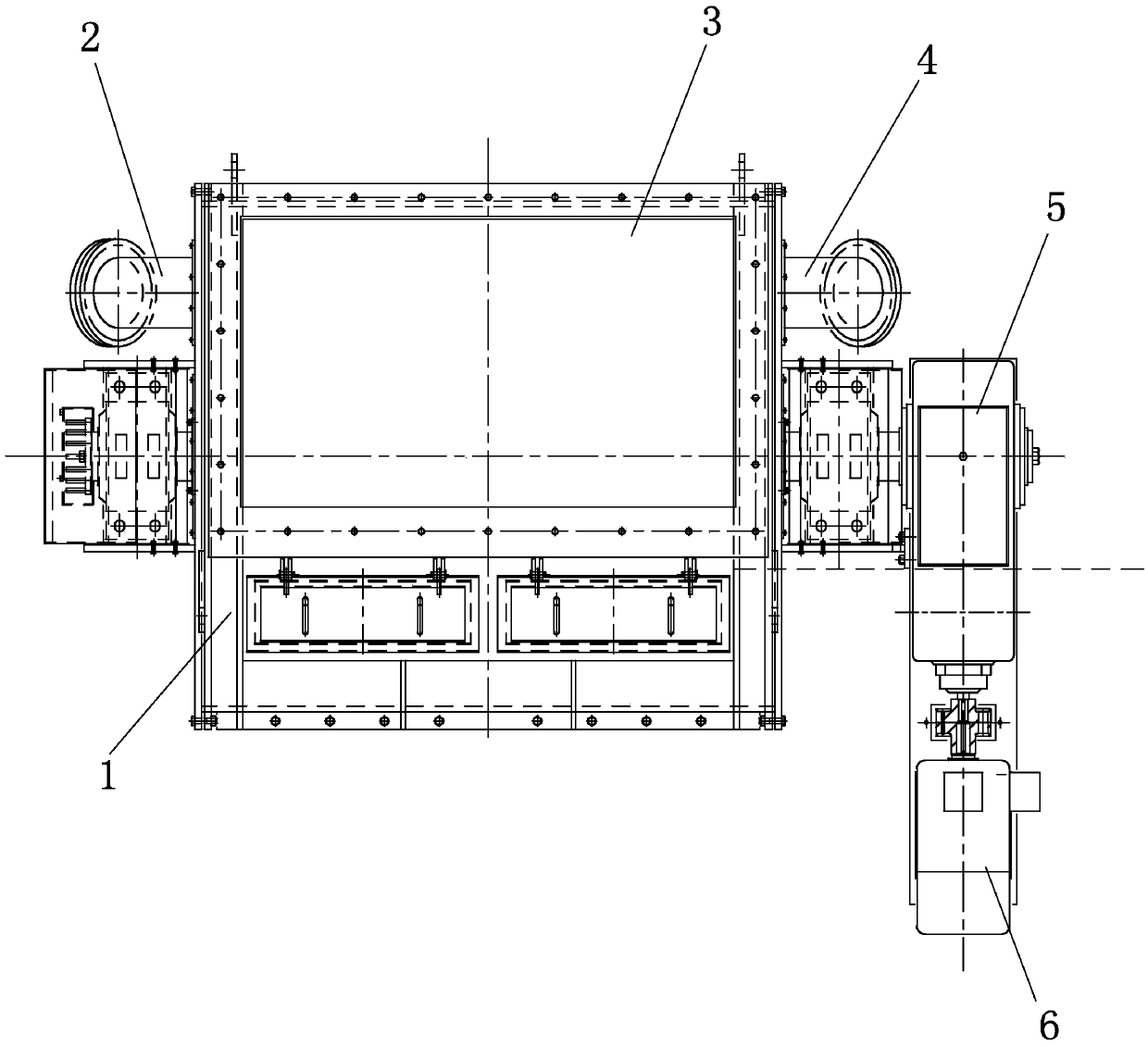

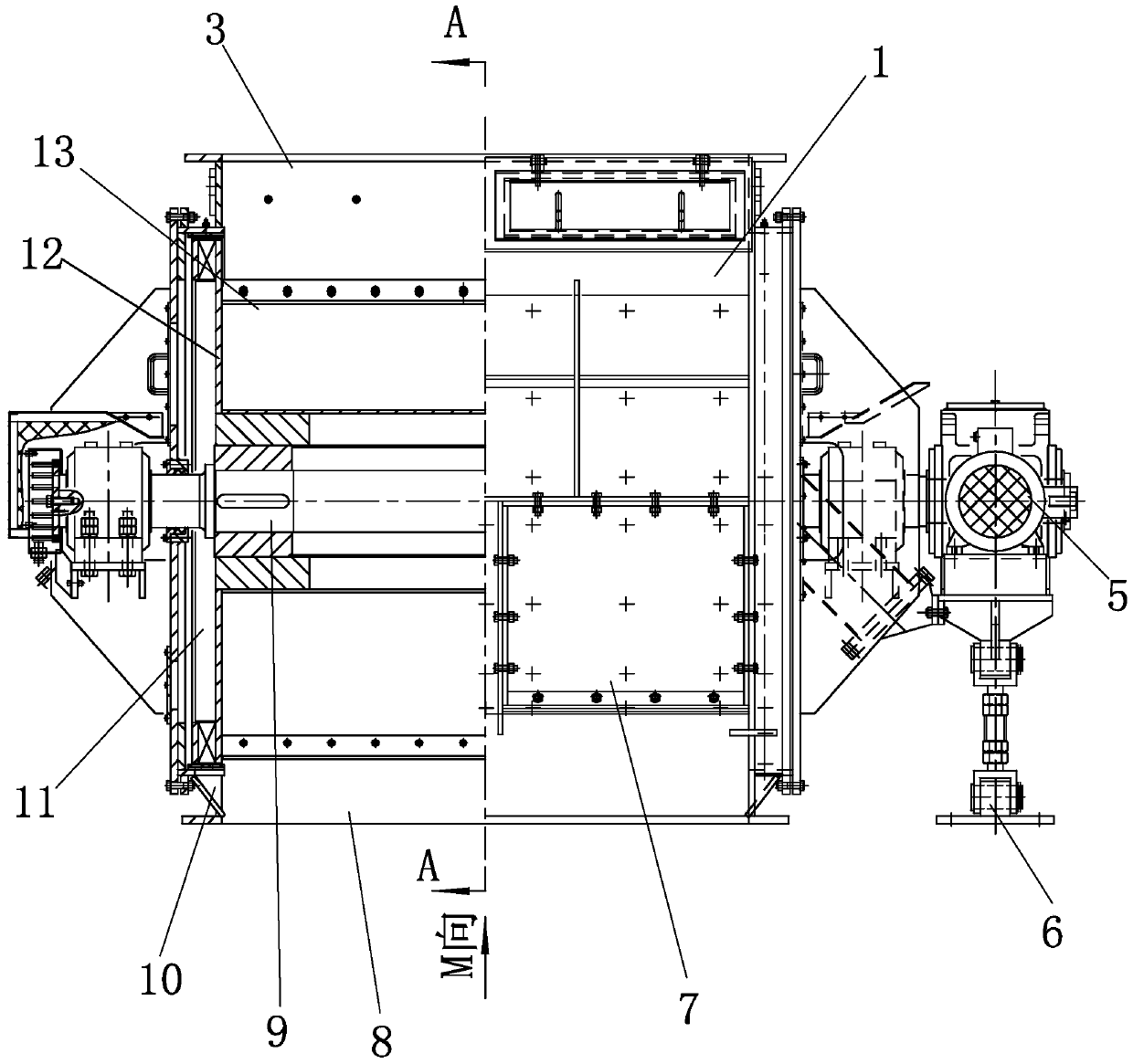

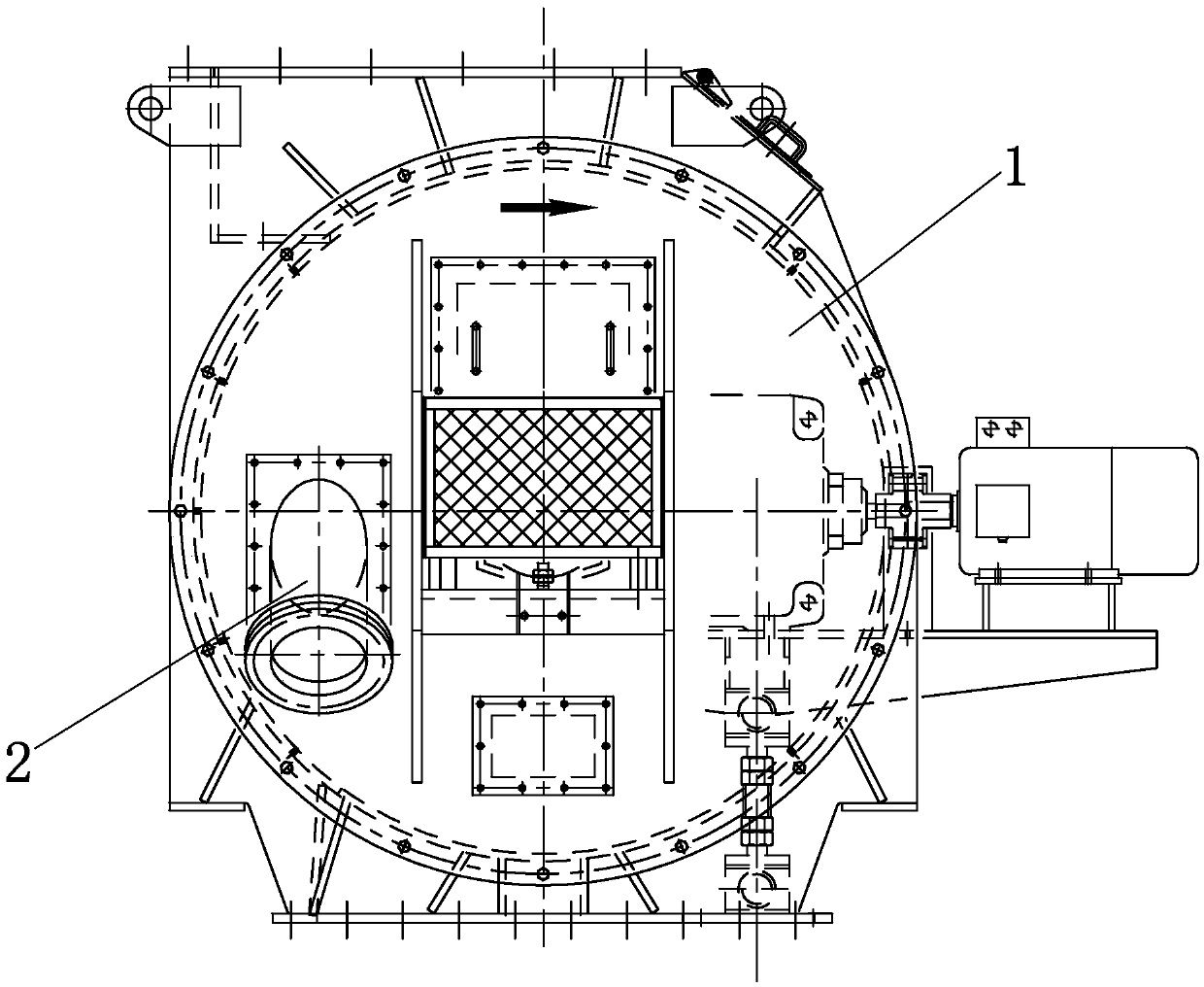

[0024] Such as Figure 1 to Figure 7 As shown, the rotary air lock feeding valve of the present invention includes a feeding valve body 1 , a driving device and a rotary feeding device arranged in the feeding valve body 1 . The feed valve body 1 is a box body welded by low-alloy high-strength steel plates. The upper end of the feed valve body 1 is provided with a feed port 3, the lower end of the feed valve body 1 is provided with a discharge port 8, and a cylindrical conveying space 18 is provided between the feed port 3 and the discharge port 8. The inner wall of the conveying space 18 is connected with a layer of inner liner 16 made of composite wear-resistant material.

[0025] The rotary feeding device includes a transmission shaft 9 and a revolving body connected outside the rotating shaft. The revolving body includes a plurality of throwing troughs 13 connected outside the drive shaft 9 in an annular array, and the ends of the groove walls 15 of adjacent throwing troug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com