High voltage electrostatic oil fume purification device

A technology for oil fume purification and high-voltage static electricity, which is used in electrode conveying devices, electrostatic separation, external electrostatic separators, etc., can solve the problems of purification function failure, increased working noise, troublesome installation and disassembly, etc., to control the virtual contact of electrodes, strengthen The effect of installation strength and avoiding safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

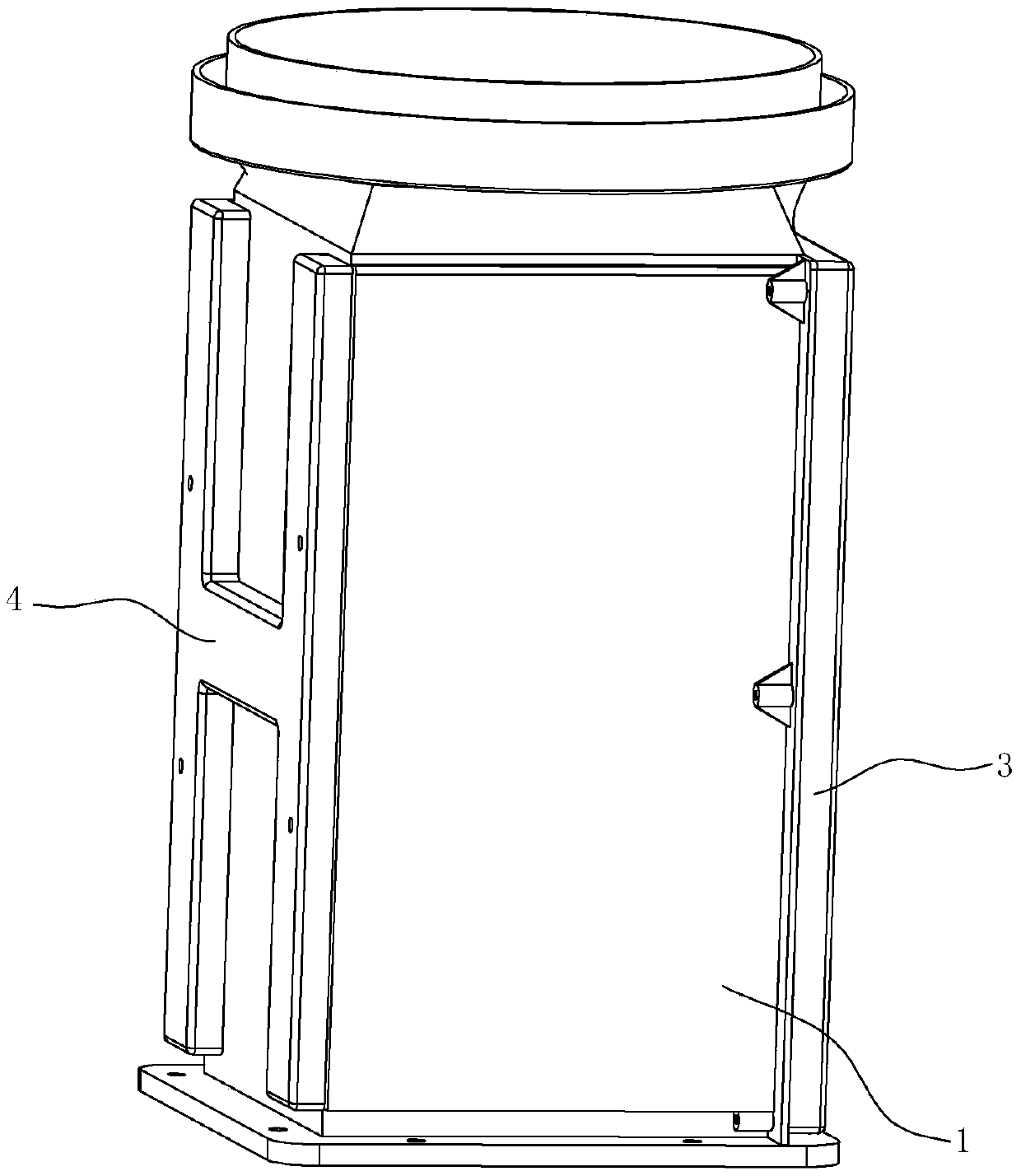

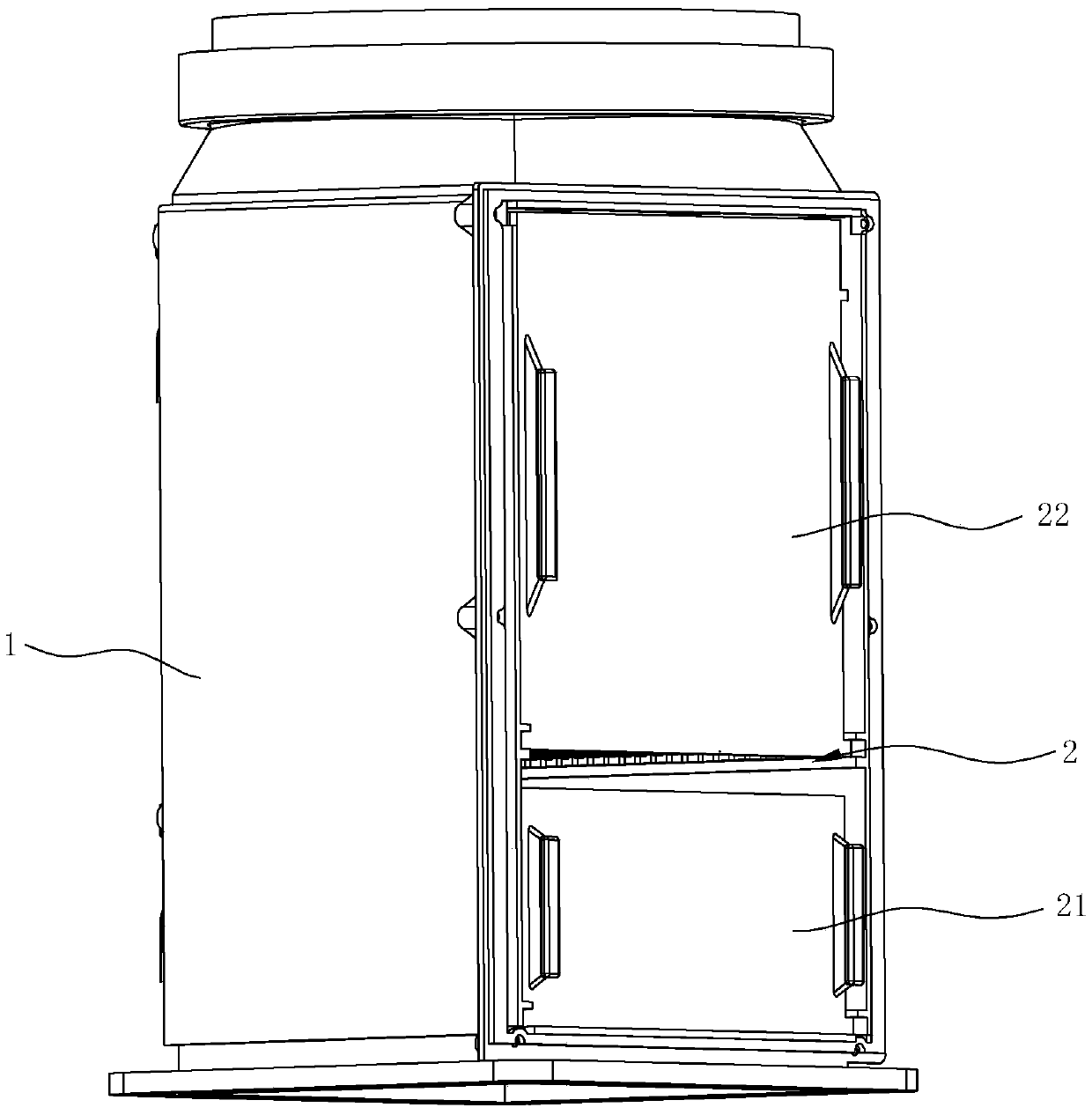

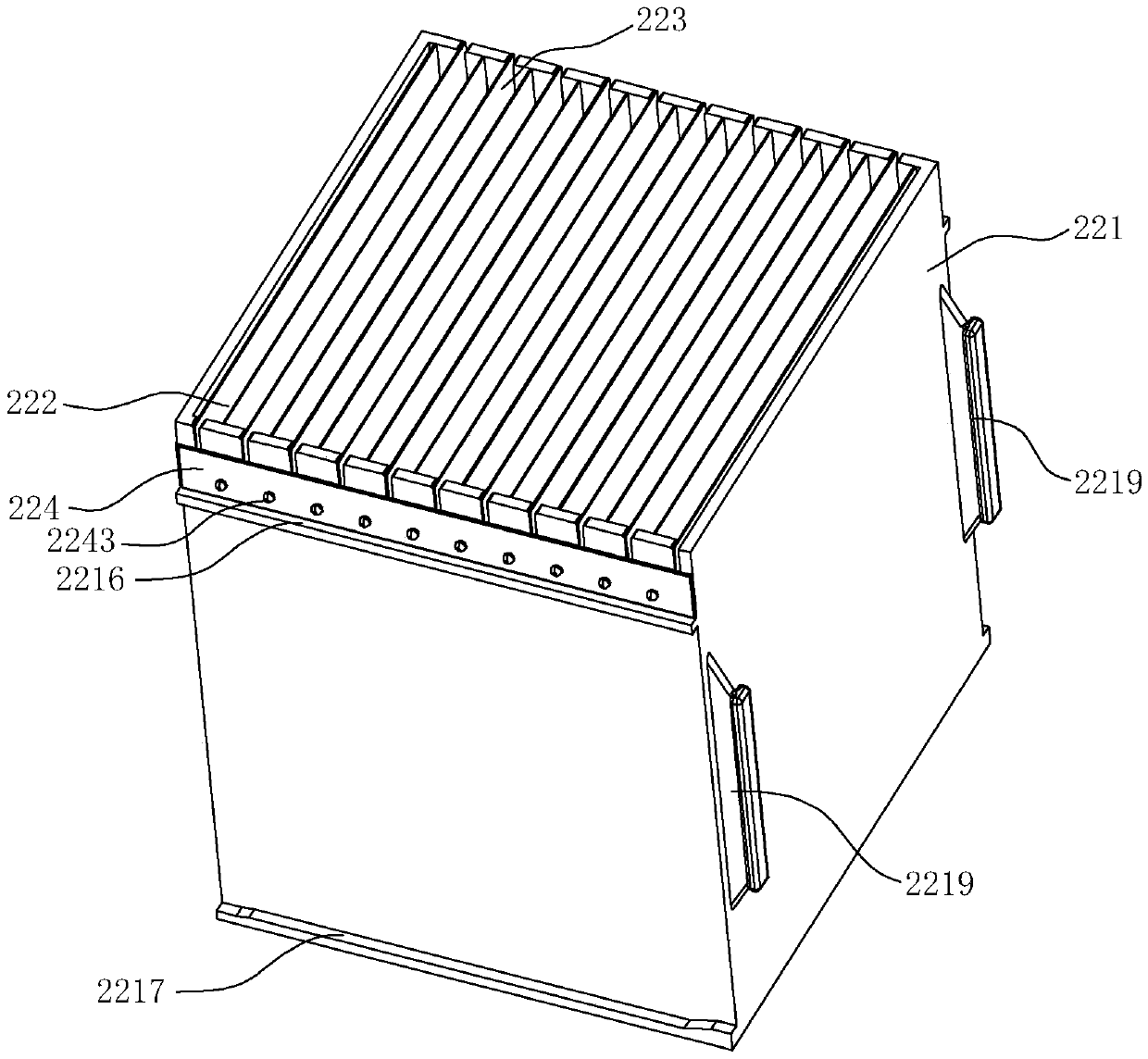

[0036] see figure 1 with figure 2 , a high-voltage electrostatic oil fume purification device, including a housing 1 and an electrostatic device 2 arranged in the housing 1, the electrostatic device 2 includes an ionization module 21 and a dust collection module 22, the dust collection module 22 is located above the ionization module 21, and the oil fume first Through the ionization of the ionization module 21 , the oil fume particles become charged particles, which are adsorbed by the electric field when passing through the dust collection module 12 upwards, thereby achieving the purpose of purifying the oil fume. The front side of the housing 1 is open and is provided with a front cover 3 , and the rear side of the housing 1 is provided with a rear cover 4 .

[0037] The structures of the ionization module 21 and the dust collection module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com