Optical automatic appearance detector

An optical automatic and detection machine technology, applied in the direction of sorting, etc., can solve the problems of uneven thickness, waste of raw materials, low utilization rate, etc., and achieve the effects of saving screening procedures, improving work efficiency, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

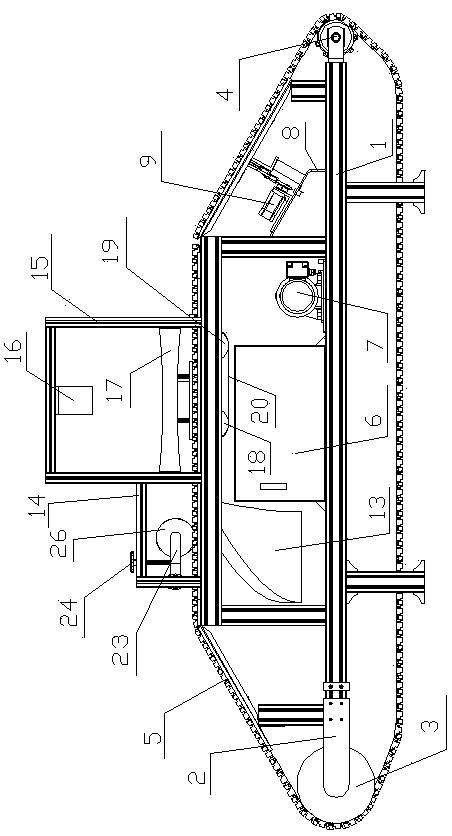

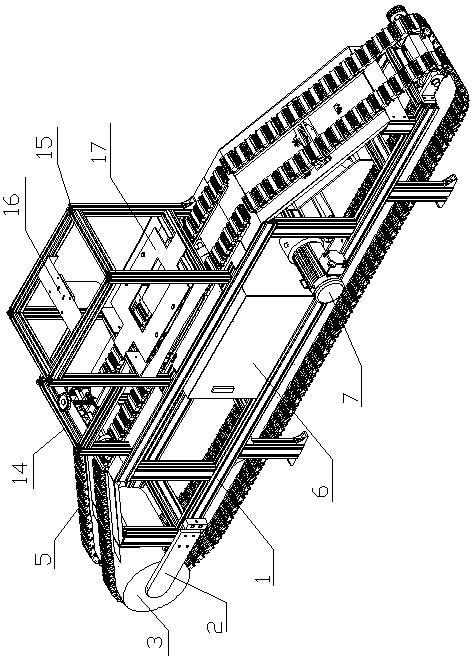

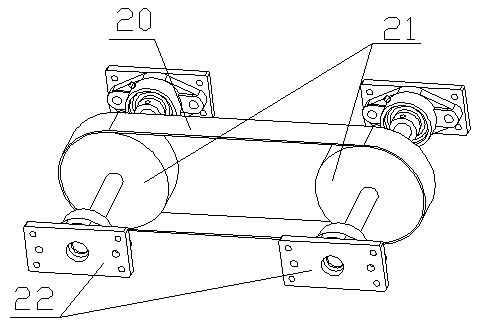

[0016] Optical automatic appearance inspection machine, the shape of the body bracket 1 is trapezoidal, the sprocket bracket 2 is fixed under the left end of the body bracket 1, the large sprocket 3 is arranged on the sprocket bracket 2, and the small sprocket is fixed under the right end of the body bracket 1 4, the small sprocket 4 and the large sprocket 3 are connected by a chain 5; the electric control cabinet 6 is fixed in the middle of the body support 1, and the reduction motor 7 is fixed on the body support 1 on the right side of the electric control cabinet 6, Then reduction motor 7 is connected with small sprocket 4 by belt, drives small sprocket 4 to rotate when reduction motor 7 works, and small sprocket 4 drives chain 5 and large sprocket 3 to operate, and the branch placed on chain 5 like this Will move thereupon, be provided with support frame 8 on the right side of reduction motor 7, support frame 8 is fixed on the body support 1, servomotor 9 and proximity swit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap