A kind of shredded crab meat method

A crab meat and shredded technology, which is applied in metal processing and other fields, can solve the problems of low manual shredding efficiency, many unstable factors, and unstable output, and achieve the effects of simple structure, convenient use, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

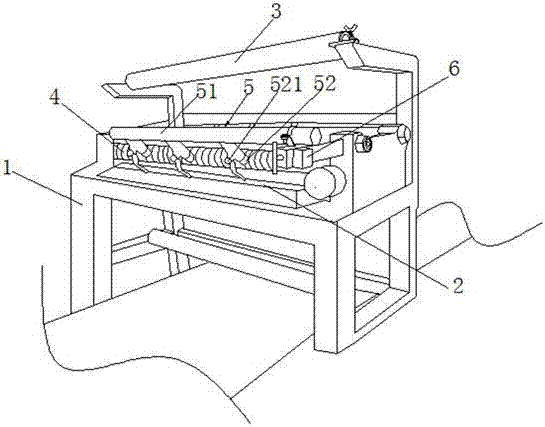

[0017] see figure 1 , a crab meat shredding machine, comprising a frame 1, a discharge platform 2 is arranged on the frame 1, a guide roller 3 is arranged above the frame 1, and a shred roller 4 is arranged on the guide roller 4. Below the lead roller 3, the thread-cutting roller 4 is evenly provided with multiple grooves along the axial direction; one side of the thread-cutting roller 4 is provided with a spray device 5, and the spray device 5 includes a water pipe 51 Several nozzles 52 connected to each other with the water pipe 51, the nozzle direction of the nozzle 52 is towards the said engraving roller 4, the nozzle 52 is provided with a valve 521, the guide roller 3 and the engraving roller 4 Driven by a motor; the frame 1 is also provided with an elevating adjustment device 6 for adjusting the distance between the engraving roller 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com