A composite core rapid pultrusion dipping process and its special dipping device

A technology of dipping device and composite core, applied in the field of composite core rapid pultrusion dipping process and its special dipping device, can solve problems such as resin waste, and achieve the effects of reducing aging speed, stable quality and reducing workload of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

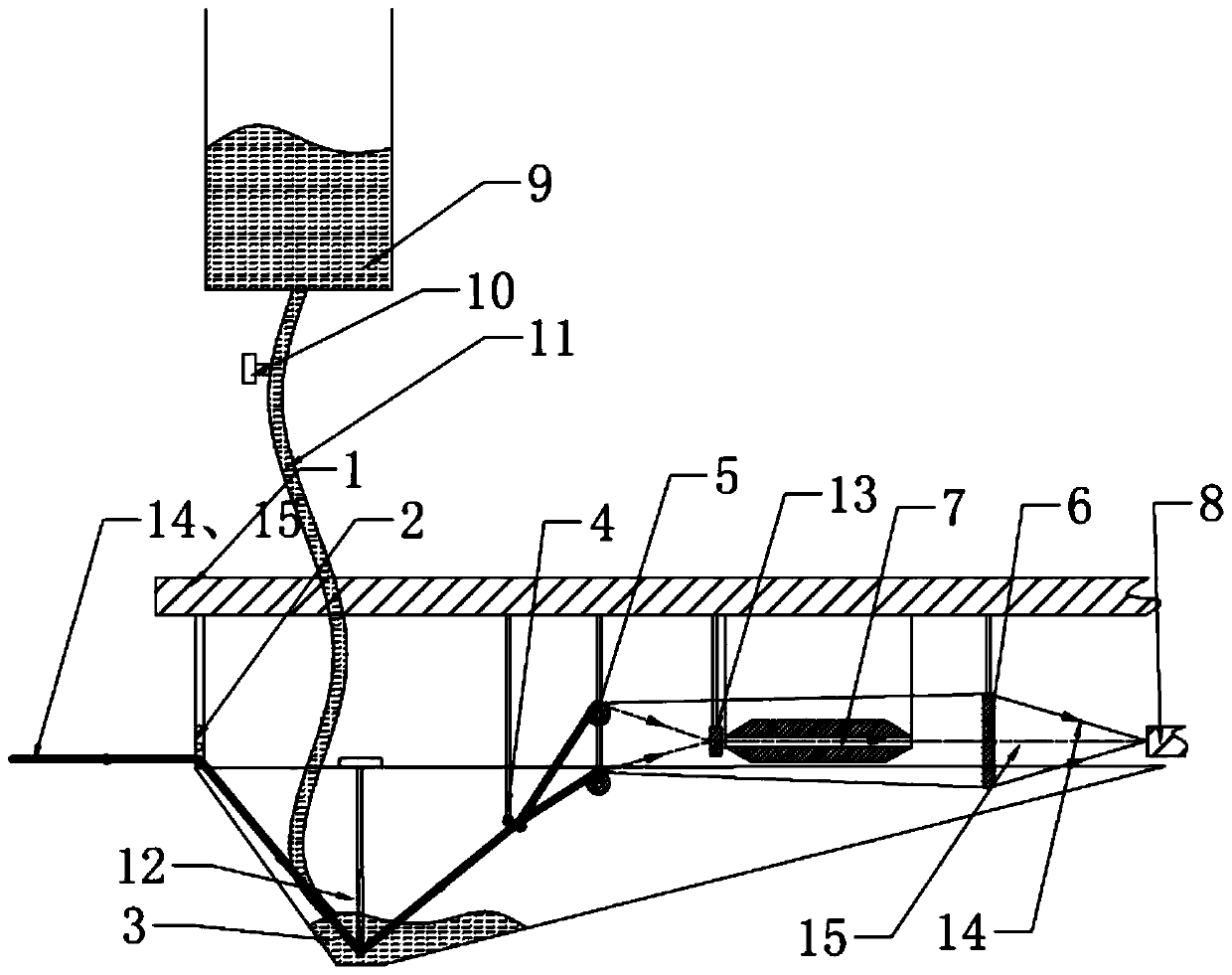

[0025] See figure 1 , a rapid pultrusion dipping device for a composite core in this embodiment, comprising a tooling support 1, a yarn splitter frame 2, a dipping tank 3, a rubber extrusion roller 4, a yarn splitter 5, a yarn collector 6, a pre-curing mold 7. Curing mold 8, resin barrel 9, control valve 10, rubber guide tube 11, pressure roller mechanism 12 and rubber scraper 13. Yarn splitter 2 is set on tooling support 1; dipping tank 3 is set under tooling support 1; squeeze rubber roller 4 and yarn splitter 5 are arranged sequentially according to the running direction of fibers; the outlet of yarn splitter 5 is divided into two ways, One way passes through the pre-curing mold 7, the yarn collector 6 and the curing mold 8 in turn, and the other way sequentially, the yarn collector 6 and the curing mold 8; Control valve 10. The amount of resin stored in the resin tank 9 can be used by the dipping equipment for 1.5 to 2 hours; the control valve 10 controls the flow of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com