Multi-pole sub-heat temperature control and multifunctional conversion set meal pot

A multi-functional, conversion sleeve technology, applied in the direction of utensils with integral electric heating device, cooking utensil lids, cooking utensils, etc., can solve the problems affecting the freshness of vegetables, lunch box pollution, environmental pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

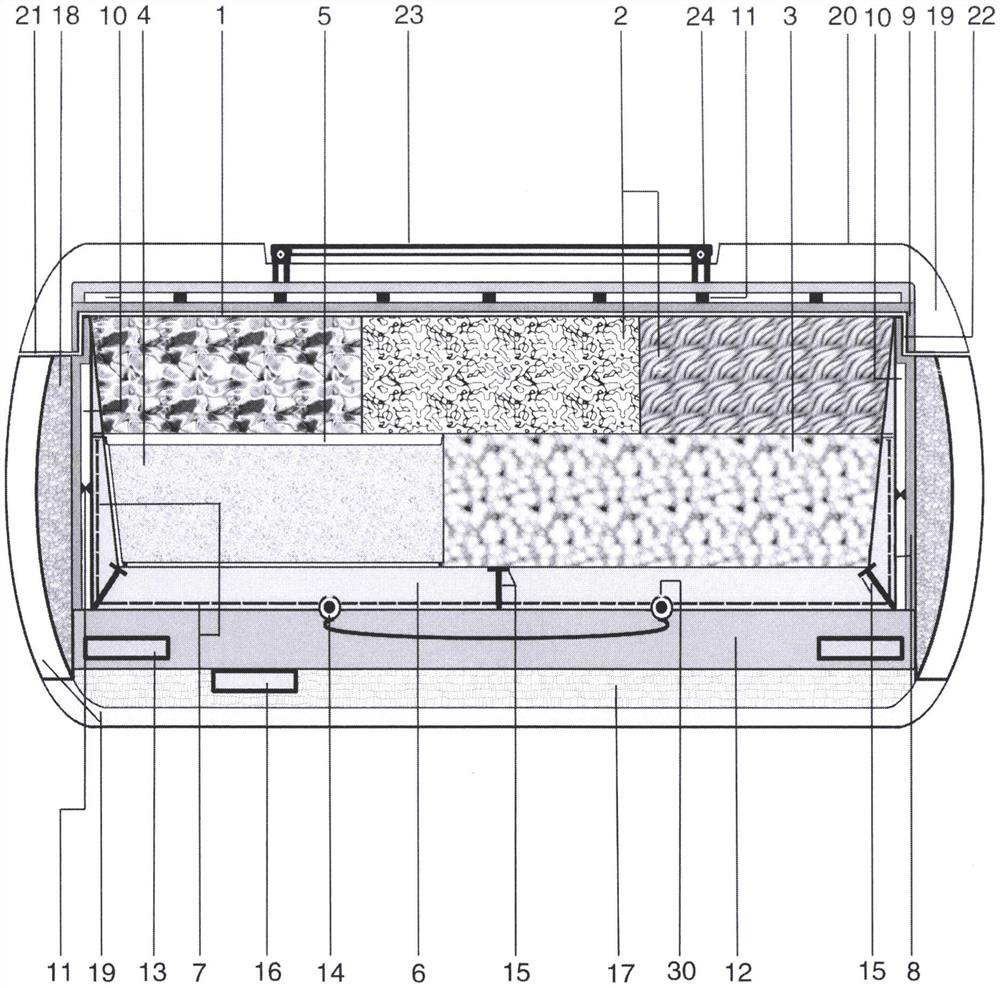

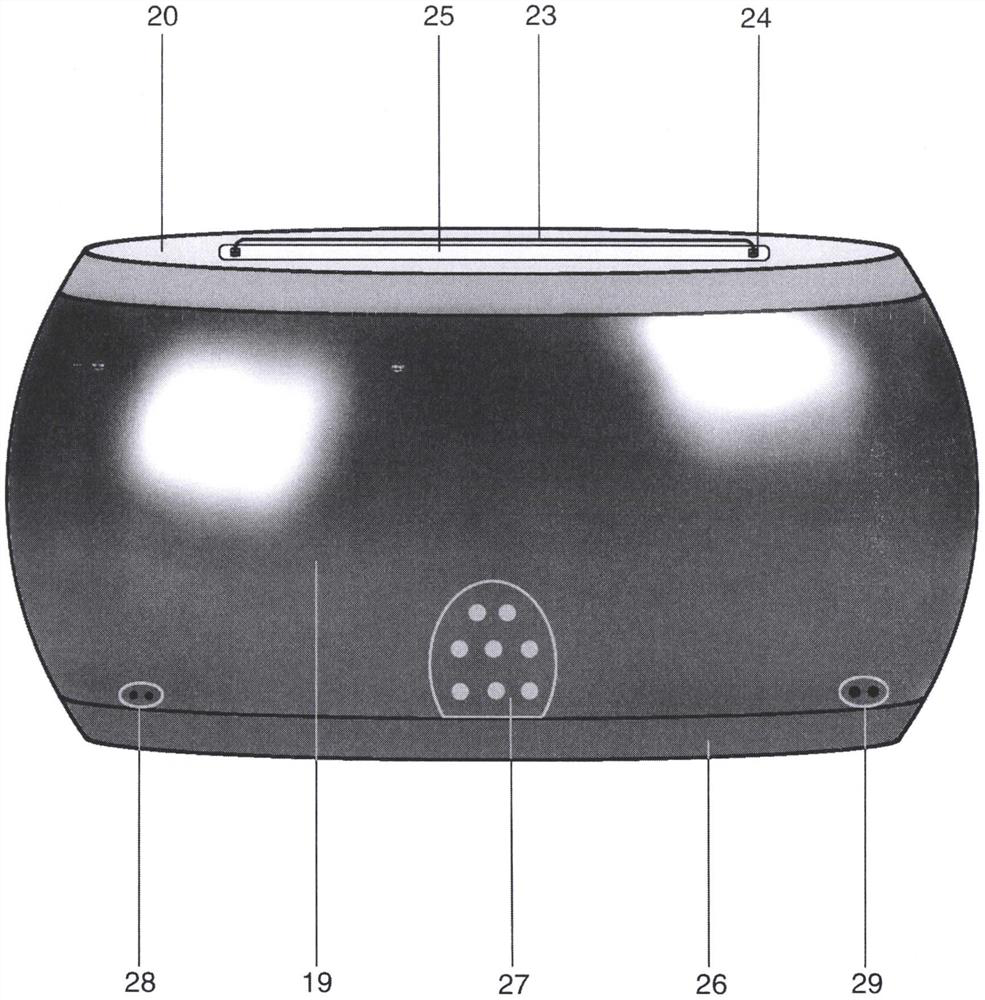

[0014] See figure 1 : The code (1) is the dish box, (2) is the different dishes in different areas, (3) is the lunch box, (4) is the soup box, (5) is the sealing cover of the soup box, (6) is the inner space of the pot, there can be Temporary cushion, (7) is filter basin, (8) is pot wall, is the interlayer of vacuum (10), (9) there is screw thread in the lower wall of the inner layer of pot cover, is closely connected with thread (22) on the outer edge of pot mouth , (11) is an anti-compressive column, (12) is a heating layer, (13) is a DC power supply, (14) is an alternating current semi-buried heating rod, (15) is a passive resistance stirring rod and a pulley, (16) is The chip box is located at the bottom of the heating layer and is not affected by high temperature. (17) is a dense foam plastic board that withstands pressure and heat preservation. The plastic material pot body shell (19) of heat-conducting material, (20) is pot cover, and (21) is wider connecting plane, is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com