Screen printing machine for conveying materials in inclined rotating manner

A screen printing machine, tilt-rotation technology, applied in screen printing machine, rotary printing machine, printing machine and other directions, can solve the problems of long training period for employees, unsatisfactory printing quality, low feeding accuracy, etc., to reduce training Cost, feeding is easy to learn, the effect of high printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

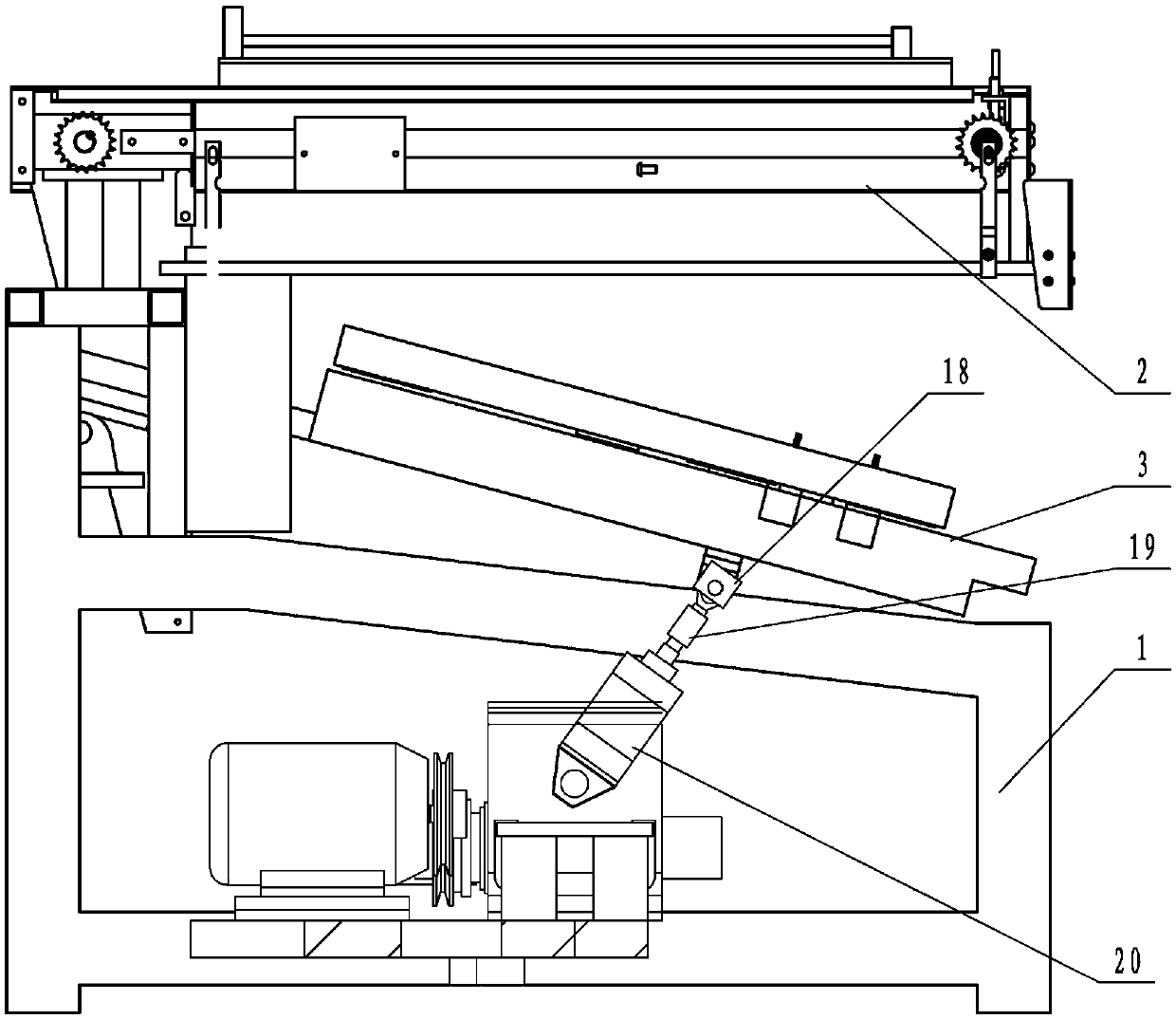

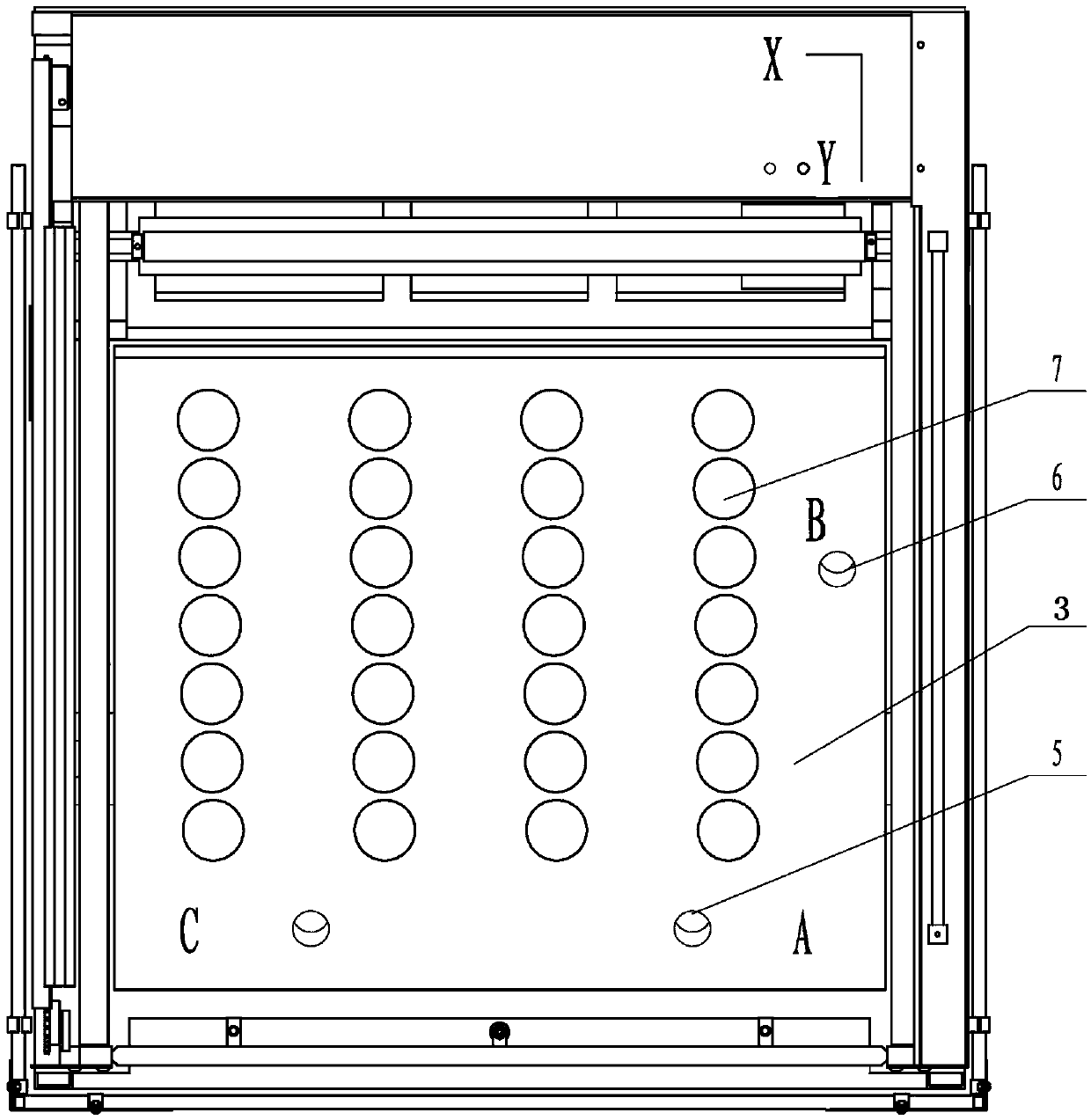

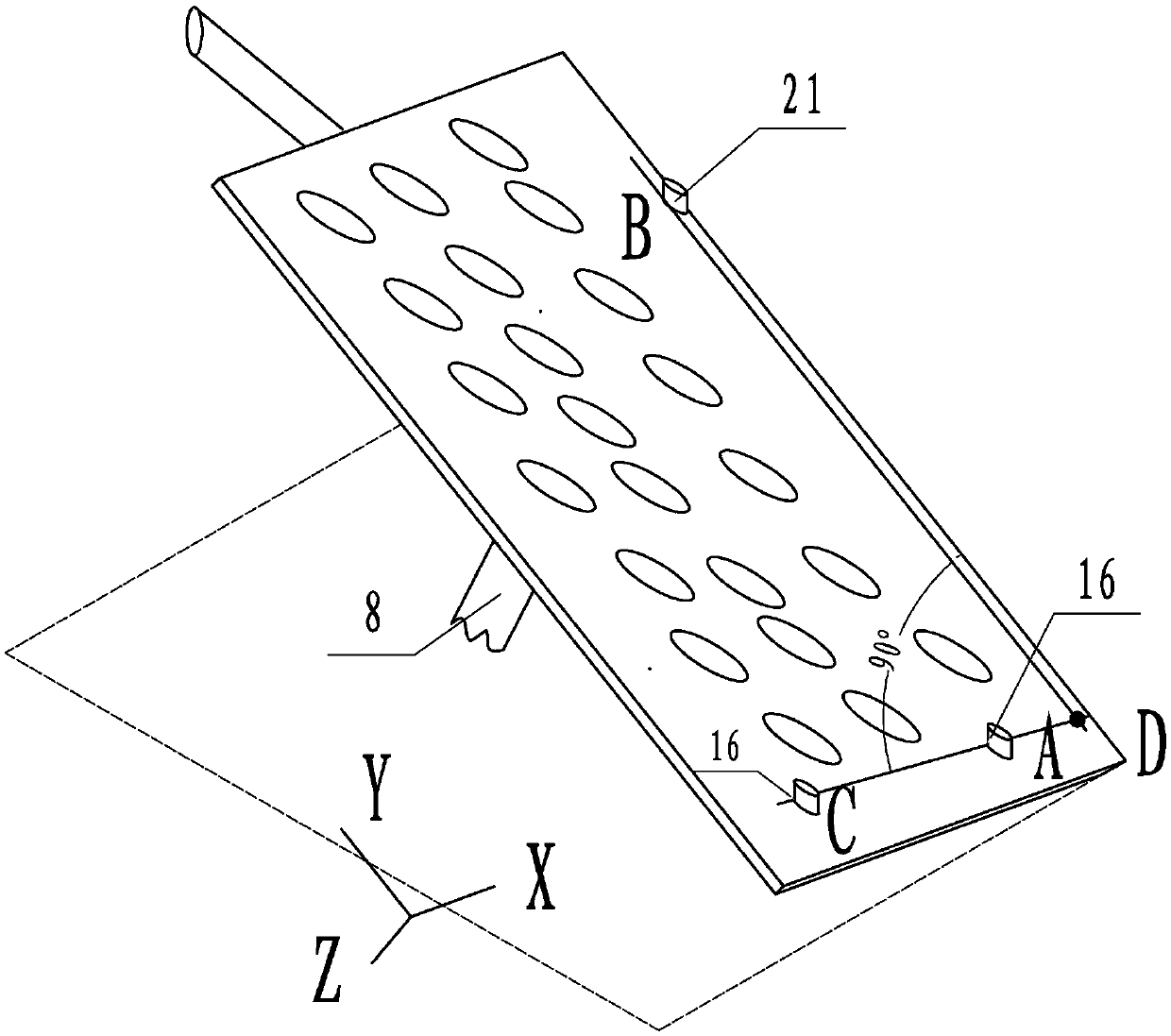

[0035] Such as Figure 1-10 As shown, the present invention includes a frame 1, a print head 2 arranged on the frame 1, and a discharge platform 3 that is engaged with the print head 2; the discharge platform 3 includes a discharge platform that is placed obliquely relative to the horizontal plane when feeding 3. The first through hole 5 and the second through hole 6 arranged on the discharge platform 3 along the Z direction. The Y-direction positioning pin 16, the contact points between the two Y-direction positioning pins 16 and the printed matter are point A and point C respectively, and the point A and point C are arranged along the X direction, and the X direction is telescopically arranged along the Z direction in the second through hole 6 Positioning pin 21, X-direction positioning pin 21 and printed matter contact point are B point, A point, B point, C point and the upper surface of discharging platform 3 to the printed matter six-point positioning; For the convenience...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com