An electrohydraulic steering device for commercial vehicles

A technology for steering devices and commercial vehicles, applied to electric steering mechanisms, power steering mechanisms, automatic steering control components, etc., can solve problems such as failure to meet energy saving and driving comfort, high power consumption of steering, etc., and meet steering safety requirements Requirements, the effect of meeting driving comfort requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

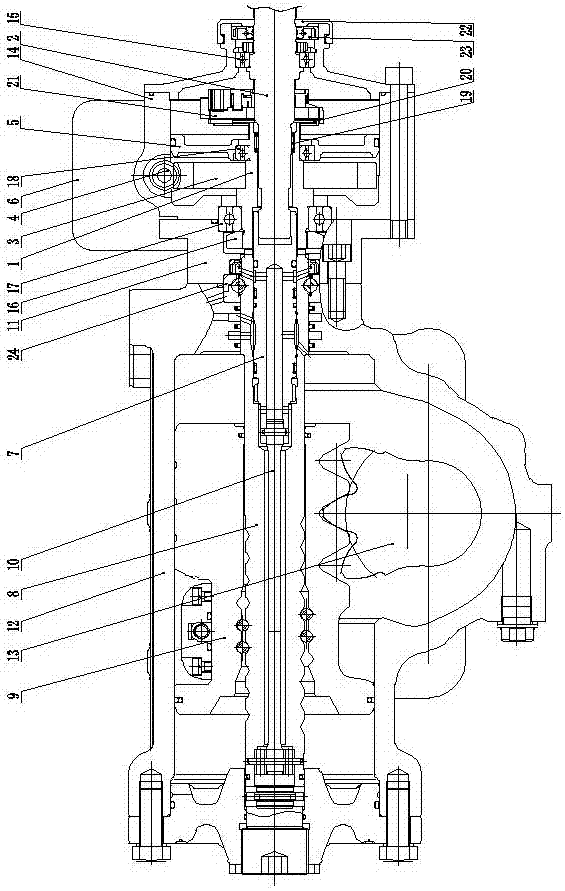

[0019] The electric hydraulic steering device for commercial vehicles consists of a recirculating ball steering gear, an intermediate shaft 1, a core shaft 2, a worm gear 3, a worm 4, a sensor, a support seat 5, a motor 6 and a controller; the recirculating ball steering gear includes an input shaft 7. Steering screw 8, steering nut 9, torsion bar 10, connecting valve body 11, steering gear housing 12 and steering arm shaft 13. The connecting valve body 11 side of the recirculating ball steering gear is fixedly equipped with an intermediate housing 14 through a connecting screw. The intermediate housing 14 is equipped with a core shaft 2 through a bearing A15. One end of the core shaft 2 is connected to the input shaft 7 of the recirculating ball steering gear. The key connection, the other end of the mandrel 2 extends to the outer end of the intermediate casing 14. An intermediate shaft 1 is movably sleeved on the core shaft 2 in the intermediate housing 14, and a bearing D19 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com