Method using soft metal braid over braid to repair helicopter main blade electric bonding sheet fracture

A technology of braided tape and soft metal is applied in the field of repairing the fracture of the main blade of the helicopter, which can solve the problems of long lap pieces, difficult bonding, and difficult bonding between the electric lap pieces and the leading edge wrapping piece. , to ensure the maintenance work, the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

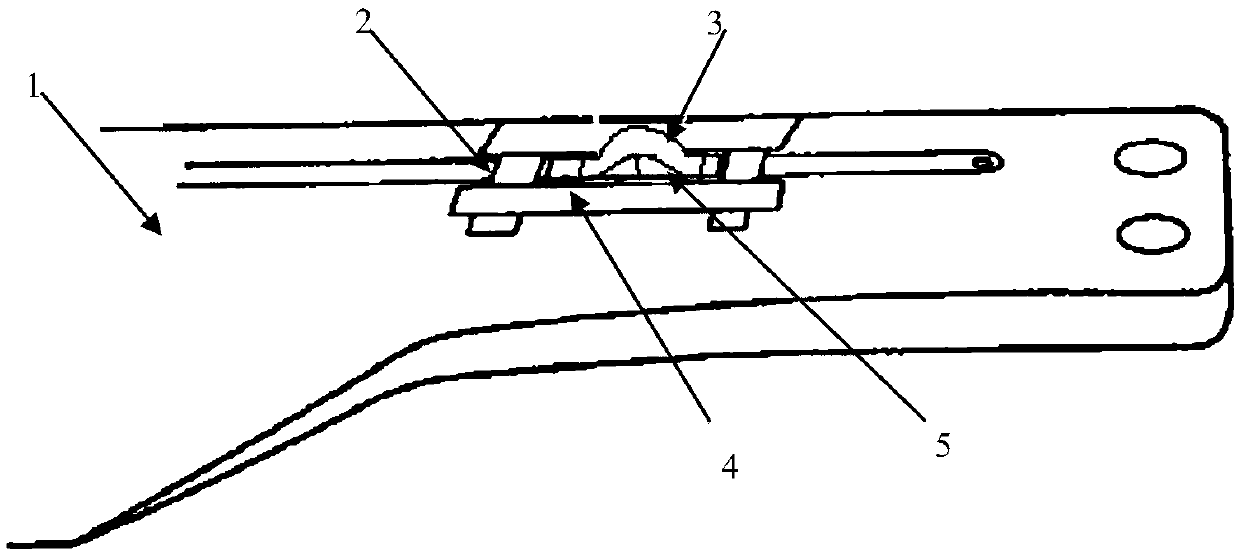

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] A method for repairing the breakage of the electric grounding piece of the main blade of a helicopter by using a soft metal braid, comprising:

[0022] (a) Use a tool to remove the excess glue on the electrical lap and the leading edge of the blade;

[0023] (b) clean the surface to be bonded with methyl ethyl ketone, and let it dry naturally for 1 hour;

[0024] (c) Fix the electrical lap and the blade. If the electrical lap and the blade are bonded with normal temperature structural adhesive, the normal temperature is 22-24 degrees Celsius, and the complete curing time is 7 days; if Use medium-temperature structural glue to bond the electrical laps of the glue-opening part to the blades, the medium temperature is 70-75 degrees Celsius, and the complete curing time is 2 hours;

[0025] (d) Remove the heating equipment, remove the clamping tool, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com