High-efficiency and low-energy-consumption sewage treatment equipment

A sewage treatment equipment and low-energy-consumption technology, which is applied in the field of high-efficiency and low-energy-consumption sewage treatment equipment, can solve the problems of high energy consumption, low efficiency, and high operating costs, and achieve low energy consumption, simple and reasonable structure, and improved sewage treatment. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

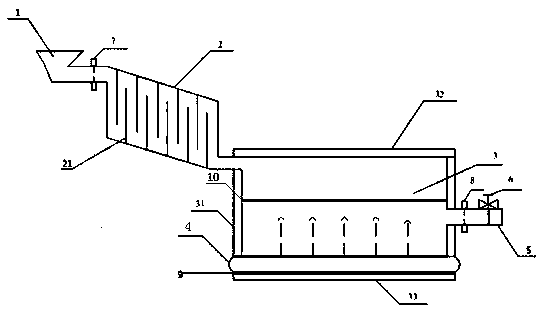

[0011] Such as figure 1 As shown, the high-efficiency and low-energy sewage treatment equipment of the present invention includes an inlet 1, a mixing chamber 2, a reaction tank 3, and an outlet 5 connected in sequence. An outlet valve 6 is also provided at the outlet 5, and the inlet 1 is arranged in an inverted trapezoidal shape. It is convenient for sewage to be treated to enter the device. The mixing chamber 2 is inclined at a certain angle, and the angle between the horizontal side and the vertical side is 20~30°. The mixing chamber 2 adopts this setting method to facilitate the liquid in the mixing chamber 2 to enter the reaction pool. In 3, the mixing chamber 2 is provided with a plurality of baffles 21 which are arranged in a staggered manner. The baffles 21 arranged in a staggered manner form a bending channel. The mixing chamber 2 is provided with grooves on the inner sides of the opposite two walls along the horizontal direction. One end of the flow plate 21 is embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com