Plate -type microporous aeration

A microporous aerator, a slat-type technology, applied in water aeration, chemical instruments and methods, sustainable biological treatment, etc., to reduce easy air leakage, increase service area, and reduce aeration dead zones.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

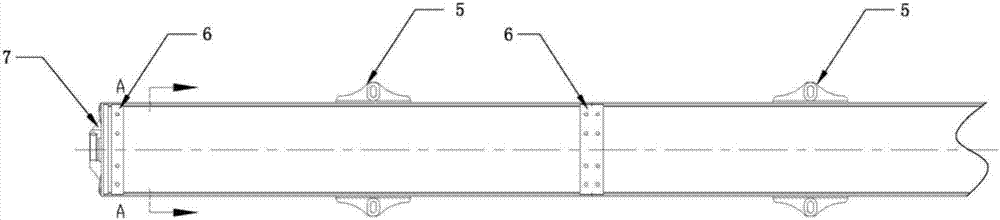

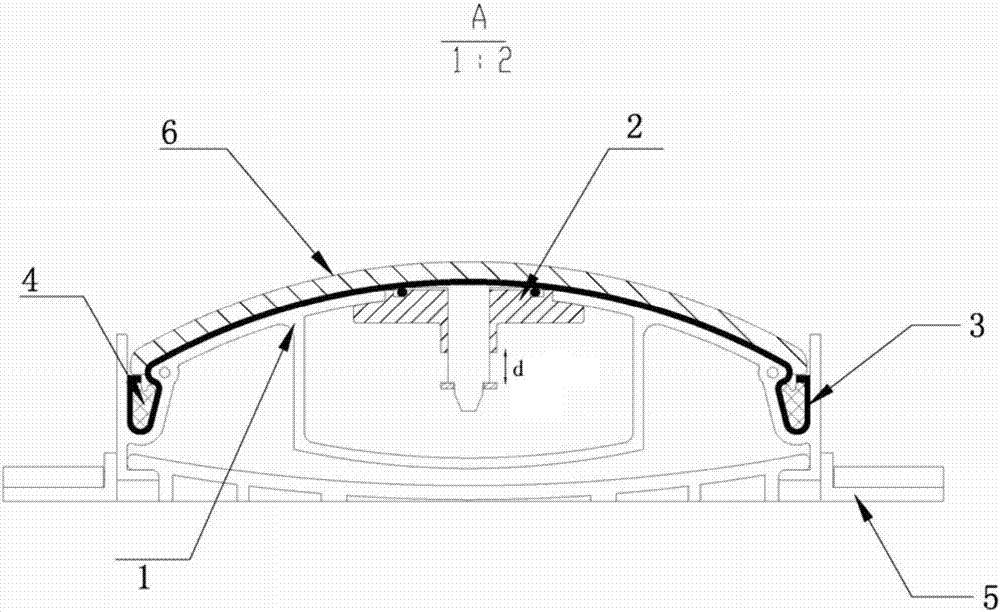

[0038] The slatted microporous aerator includes an arc-shaped slat 1, a non-resistance check valve 2, a rubber aeration diaphragm 3, a V-shaped bead 4, a plug-in connection bottom plate 5, a pressure plate 6 and an end cover 7.

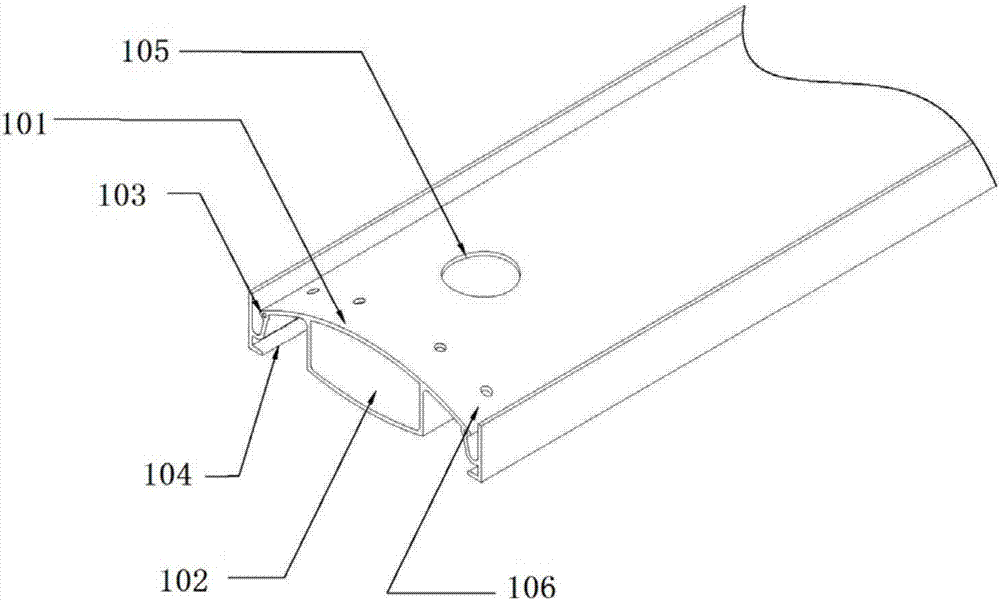

[0039] Among them, the top of the arc-shaped slat 1 is an arc-shaped plate 101, and the arc-shaped plate 101 of the arc-shaped slat 1 has a non-resistance check valve installation hole 105 at an interval of 500mm along the length direction, and the arc-shaped plate 101 is provided with a flat square The air distribution channel 102 (the size of the cross-section is 45mm×100mm), the two sides of the arc-shaped slat 1 are provided with a V-shaped slot 103 with convex points, and the lower part of the V-shaped slot 103 extends inward to form an arc. The slat 1 is fixed on the L-shaped buckle 104 on the plug-in board connection base plate 5 .

[0040] The rubber aeration membrane 3 is densely covered with staggered 20-40° aeration holes 301, and the non-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com