Jet Aerating Reactor

A technology of jet aeration and reactor, applied in the direction of water aeration, fluid mixer, chemical instrument and method, etc., can solve the problem of poor propulsion performance, poor mixing effect of water and gas, and insufficient oxygenation capacity in the boundary area of jet flow Ideal and other issues, to achieve the effect of improving convection and diffusion capacity, small diameter, and enhanced turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

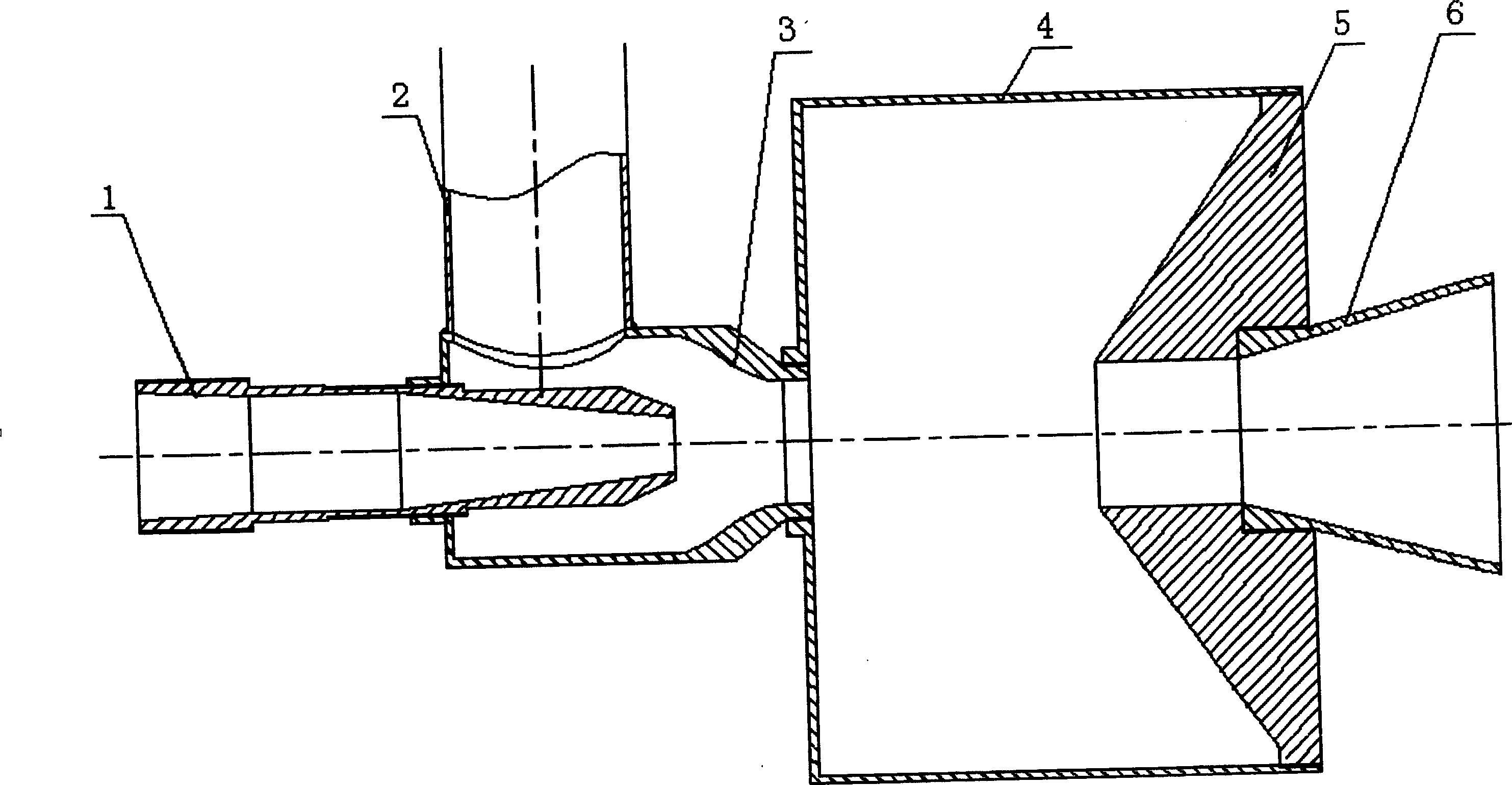

[0011] Nozzle 1, upper nozzle body 3, self-excited oscillating mixing chamber 4, lower nozzle body 5 and short pipe 6 are installed on the same center line in sequence, and the suction pipe 2 is vertically installed on the outer surface of the hollow cylindrical section of the upper nozzle body . The through hole in the nozzle 1 is composed of a cylindrical hole and a conical hole, and the cone angle of the conical hole is 12.5°-13.5°. The connection mode between the nozzle 1 and the upper nozzle body 3 is screw connection or welding or flange connection. The purpose of designing the inner contour curve of the suction chamber in the upper nozzle body is to improve the flow coefficient of the two-phase flow of water and gas entering the inlet hole of the self-excited oscillation mixing chamber. The inner contour curve is a straight line segment and an outwardly convex transition circle The arc and the inwardly concave high-degree equation curve are smoothly connected in turn. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com