Rotary hearth furnace thermal control method for directly reducing carbon-containing pellets

A control method and technology of rotary hearth furnace, applied in the direction of furnace, hearth furnace, furnace type, etc., can solve problems such as complex process, improve mixing conditions, improve thermal efficiency of equipment, and reduce pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

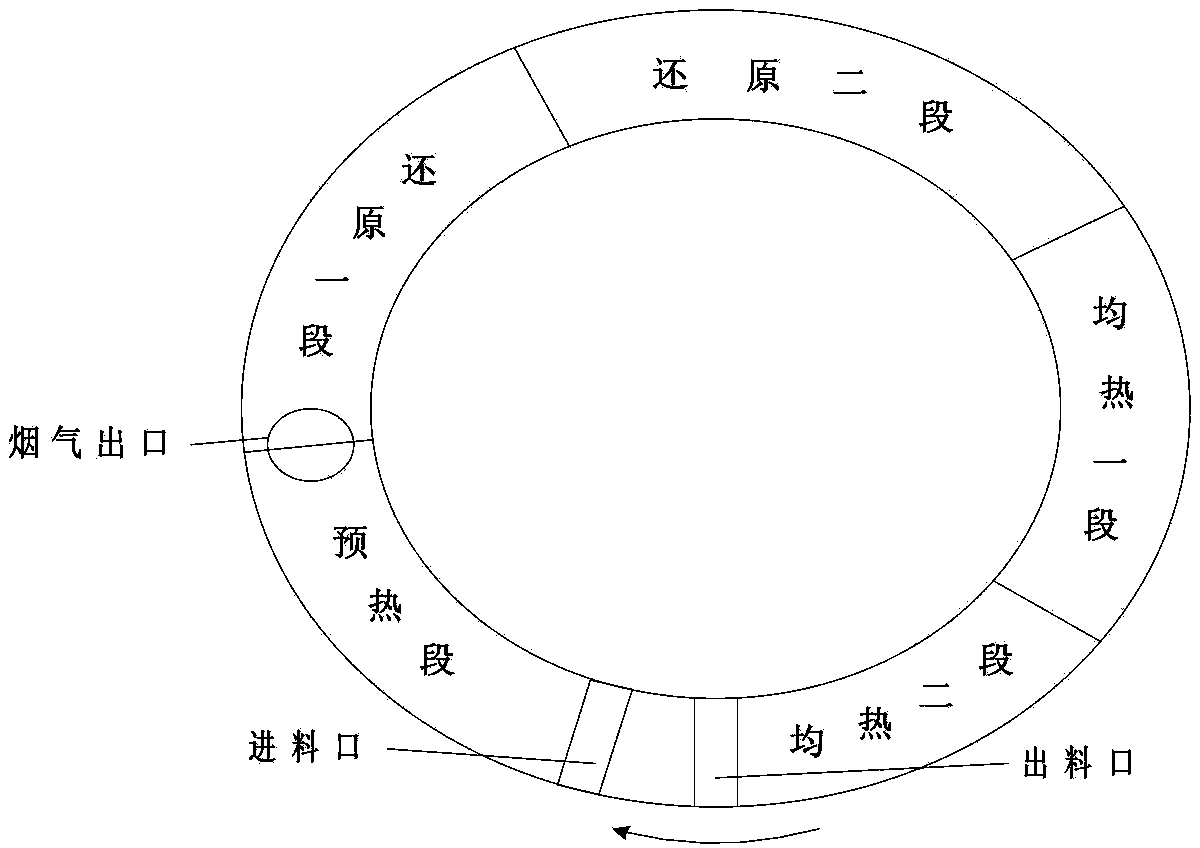

[0031] The bottom width of the rotary hearth furnace in the example of the present invention is 5m, and the effective area is 412m 2 . The whole furnace is divided into preheating section, reduction section I, reduction section II, soaking section I and soaking section II from the feed end to the discharge end in sequence, and the smoke exhaust port of the furnace is set between the preheating section and reduction section I . The overall structure of the rotary hearth furnace is as follows: figure 1 shown. The parameters of carbon-containing pellets (green pellets) in the furnace are shown in Table 1.

[0032] Table 1 Parameters of carbon-containing pellets (green pellets) in the furnace (%)

[0033] TF

Fe 2 o 3

FeO

CaO

SiO 2

al 2 o 3

MgO

S

P

C

other

48.60

50.86

16.71

3.36

4.38

0.95

1.42

0.71

0.05

14.25

5.15

[0034] The temperature...

Embodiment 2

[0051] The bottom width of the rotary hearth furnace in the example of the present invention is 2m, and the effective area is 56m 2 . The parameters of the carbon-containing pellets (green pellets) entering the furnace and the temperature of the carbon-containing pellets entering the furnace are the same as in Example 1.

[0052] The thermal control method of the rotary hearth furnace for direct reduction of carbon-containing pellets includes three aspects: furnace temperature control, furnace gas composition control and air supply:

[0053] (1) Control of blast furnace temperature

[0054] The control furnace temperature of each section of the rotary hearth furnace is as follows:

[0055] 1) Control the furnace temperature at 1050°C in the preheating section;

[0056] 2) Control the furnace temperature at 1200°C in the reduction section I and reduction section II;

[0057] 3) Control the furnace temperature at 1180°C in the soaking section I, and control the furnace tempe...

Embodiment 3

[0068] The bottom width of the rotary hearth furnace in the example of the present invention is 3m, and the effective area is 100m 2 . The parameters of the carbon-containing pellets (green pellets) entering the furnace and the temperature of the carbon-containing pellets entering the furnace are the same as in Example 1.

[0069] The thermal control method of the rotary hearth furnace for direct reduction of carbon-containing pellets includes three aspects: furnace temperature control, furnace gas composition control and air supply:

[0070] (1) Control of blast furnace temperature

[0071] The control furnace temperature of each section of the rotary hearth furnace is as follows:

[0072] 1) Control the furnace temperature at 1150°C in the preheating section;

[0073] 2) Control the furnace temperature at 1300°C in the reduction stage I and reduction stage II;

[0074] 3) Control the furnace temperature at 1300°C in the soaking section I, and control the furnace temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com