A method for adding bismuth in the smelting of bismuth-containing high magnetic induction oriented silicon steel

A high magnetic induction oriented, silicon steel technology, applied in the field of adding bismuth in the smelting of bismuth-containing high magnetic induction oriented silicon steel, can solve problems such as unfavorable handling and storage, and the feeding pipe is easily blocked by steel slag, and achieves improved yield and simple addition. , the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below:

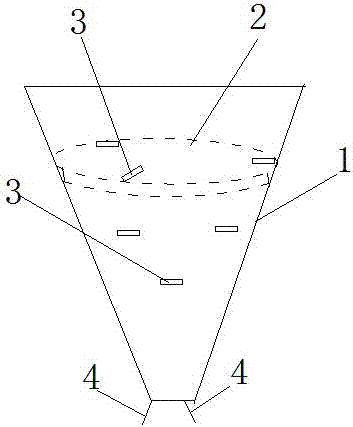

[0026] First in conjunction with the accompanying drawings, the filled bismuth block container used in the present invention is specifically described:

[0027] The bismuth block container consists of a conical barrel body 1, a bung 2 fastened to the upper end of the conical barrel body 1, and a release hole 3 with a hole diameter less than 10mm processed on the bung lid 2 and the conical barrel body 1. In order to make the container of containing bismuth blocks placed stably, the lower end of the conical barrel body 1 is welded or bolted with a claw-like or triangular stable frame 4. The barrel cover 2 and the tapered barrel body 1 are made of iron plates containing no less than 70wt% iron, and the thickness is no less than 0.2mm.

[0028] The container of containing bismuth blocks described in each of the following embodiments all adopts this container.

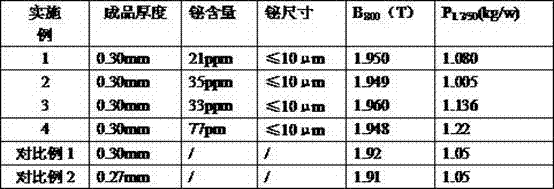

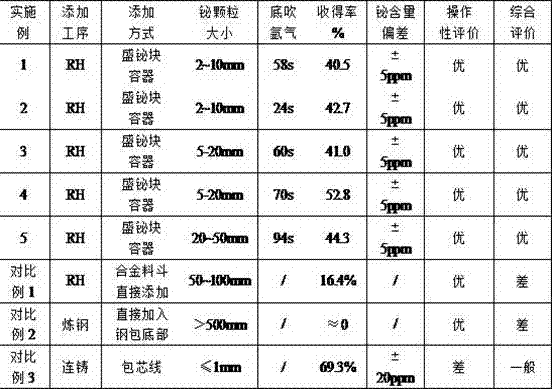

[0029] Table 1 is the value list of the main process param...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com