A horizontal screw conveying sludge cleaning equipment and its cleaning method

A horizontal screw and cleaning equipment technology, which is applied in construction, earth mover/excavator, etc., can solve the problems of expensive equipment, sedimentation sites, environmental pollution, and large energy consumption of dredging equipment, so as to save the mixing process , The structure of the equipment is simple, and the effect of energy saving is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

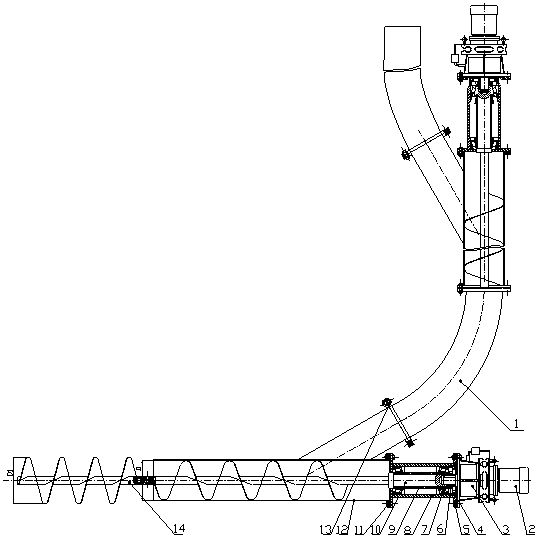

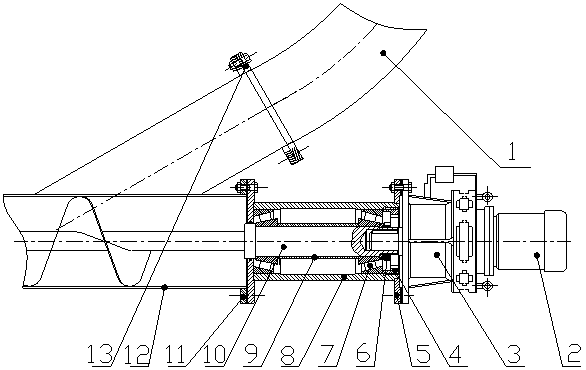

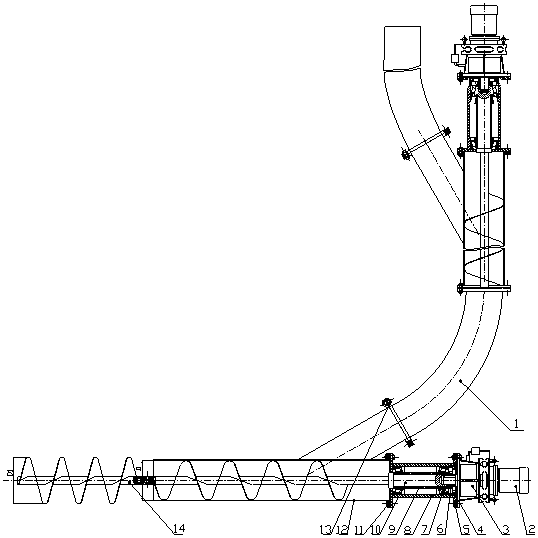

[0024] Such as figure 1 As shown, the horizontal screw conveying sludge cleaning equipment mainly includes a horizontal screw tunneling device located at the low position and a vertical screw conveying device located at the high position continuously and multi-staged from bottom to top. There are multiple screw conveying devices. The screw conveying device is named according to the order of the first level, the second level, the third level..., the structure of the longitudinal screw conveying device and the horizontal screw driving device are basically the same, the difference lies in the method of placement, and the front end of the horizontal screw driving device has a The excavation section that excavates the soil.

[0025] The left-handed helical shaft 14 with left-handed helical blades connected to the left end of the auger of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com