Method for recognizing efficiency of aircraft elevator

An identification method and elevator technology, applied in the testing of machines/structural components, power measurement, measuring devices, etc., can solve the problems of high cost, high risk, and low accuracy of results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

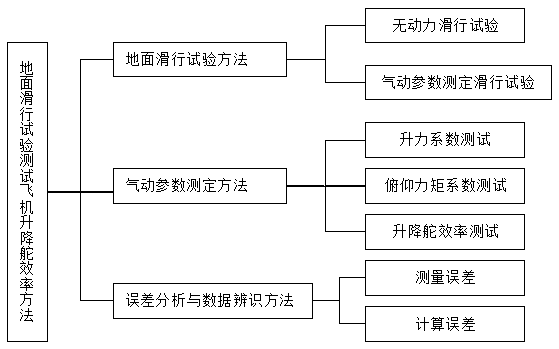

[0091] A method for identifying the efficiency of an aircraft elevator, characterized in that it comprises: a. ground taxiing test method, b. aerodynamic parameter measurement method and c. error analysis and data identification method, said ground taxiing test method comprising: and a2 aerodynamic parameter determination sliding test, the aerodynamic parameter determination method includes: b1 lift coefficient test, b2 pitching moment coefficient test and b3 elevator efficiency test, the error analysis and data identification method includes: c1 measurement error and c2 calculation error.

[0092] The a. ground sliding test method

[0093] a1. Unpowered sliding test

[0094] The non-powered taxiing test is carried out by a tractor. Through the non-powered taxiing test, some control capabilities of the aircraft's flight control (such as deviation correction), the working conditions of the landing gear and the braking system, and the working conditions of the various systems of...

Embodiment 2

[0159] A method for identifying the efficiency of an aircraft elevator, characterized in that it comprises: a. ground taxiing test method, b. aerodynamic parameter measurement method and c. error analysis and data identification method, said ground taxiing test method comprising: and a2 aerodynamic parameter determination sliding test, the aerodynamic parameter determination method includes: b1 lift coefficient test, b2 pitching moment coefficient test and b3 elevator efficiency test, the error analysis and data identification method includes: c1 measurement error and c2 calculation error.

[0160] The a. ground sliding test method

[0161] a1. Unpowered sliding test

[0162] The non-powered taxiing test is carried out by a tractor. Through the non-powered taxiing test, some control capabilities of the aircraft's flight control (such as deviation correction), the working conditions of the landing gear and the braking system, and the working conditions of the various systems of...

Embodiment 3

[0227] A method for identifying the efficiency of an aircraft elevator, characterized in that it comprises: a. ground taxiing test method, b. aerodynamic parameter measurement method and c. error analysis and data identification method, said ground taxiing test method comprising: and a2 aerodynamic parameter determination sliding test, the aerodynamic parameter determination method includes: b1 lift coefficient test, b2 pitching moment coefficient test and b3 elevator efficiency test, the error analysis and data identification method includes: c1 measurement error and c2 calculation error.

[0228] The a. ground sliding test method

[0229] a1. Unpowered sliding test

[0230] The non-powered taxiing test is carried out by a tractor. Through the non-powered taxiing test, some control capabilities of the aircraft's flight control (such as deviation correction), the working conditions of the landing gear and the braking system, and the working conditions of the various systems of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com