Mechanical apparatus applied to calibration of torque sensor, and method

A technology of torque sensor and mechanical device, applied in the direction of force/torque/power measuring instrument calibration/test, measuring device, instrument, etc., it can solve the problems of narrow applicable range, small torque range, large torque loss, etc., and achieve reading Convenience, accurate calibration results, and large measuring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

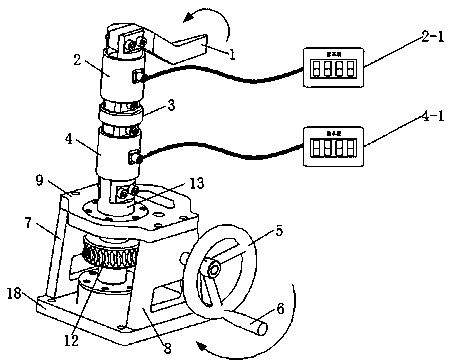

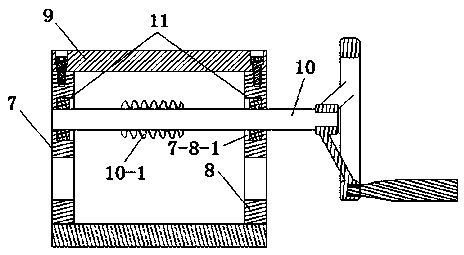

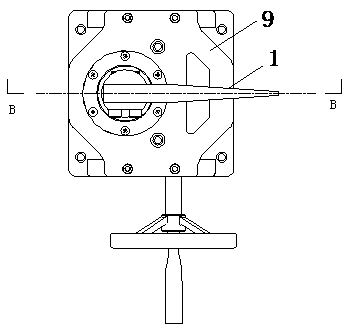

[0022] like Figure 1 to Figure 9 As shown, a mechanical device applied to torque sensor calibration includes a sensor 2 to be calibrated connected with a digital display meter 2-1 of the sensor to be calibrated and a standard sensor 4 connected with a digital display meter 4-1 of a standard sensor, and also includes a force transmission Plate 1, connecting block 3, hand wheel 5, handle 6, left bracket 7, right bracket 8, upper bracket 9, worm 10, worm bearing 11, turbine 12, main shaft 13, main shaft bearing I 14, main shaft bearing I bearing cover 15, Main shaft bearing II 16, main shaft bearing II bearing cover 17, base 18.

[0023] The connection block 3 is a circular block, and a rectangular protrusion II3-1 is respectively provided on the upper and lower surfaces of the circular block, and a fixing hole II3-2 is respectively provided on the surfaces of the two rectangular protrusions II3-1.

[0024] The main shaft 13 is a stepped cylindrical shape, a rectangular protrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com