Method for testing current distribution uniformity inside single voltage-dependent resistor valve block within wide temperature range

A varistor and current distribution technology, applied in the direction of current density measurement, etc., can solve the problems of overheating, breakdown of the resistor, and the inability to test the current uniformity of the zinc oxide varistor valve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] According to the method for testing the uniformity of current distribution inside the varistor valve with a wide temperature range introduced in the patent specification of the present invention, the zinc oxide varistor valve was tested for the uniformity of current distribution. The specific process is as follows:

[0034] (1) For the thickness d=2mm, the upper and lower surface areas are each A=13.75mm 2 Polish the upper and lower surfaces of the zinc oxide varistor valve plate, so that the roughness of the upper and lower surfaces of the zinc oxide varistor valve plate is less than 1 micron;

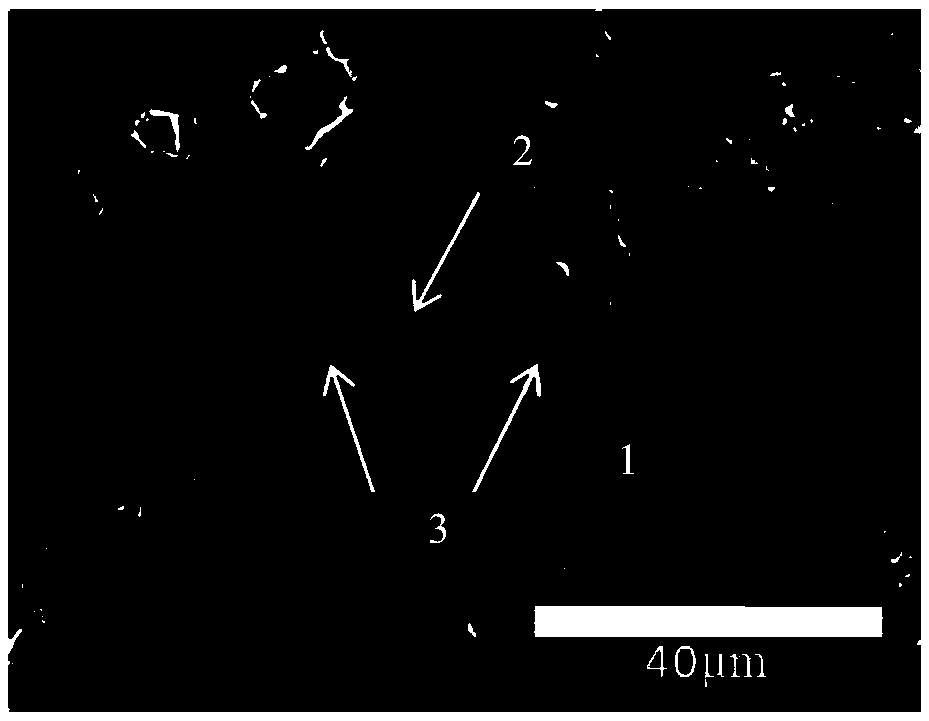

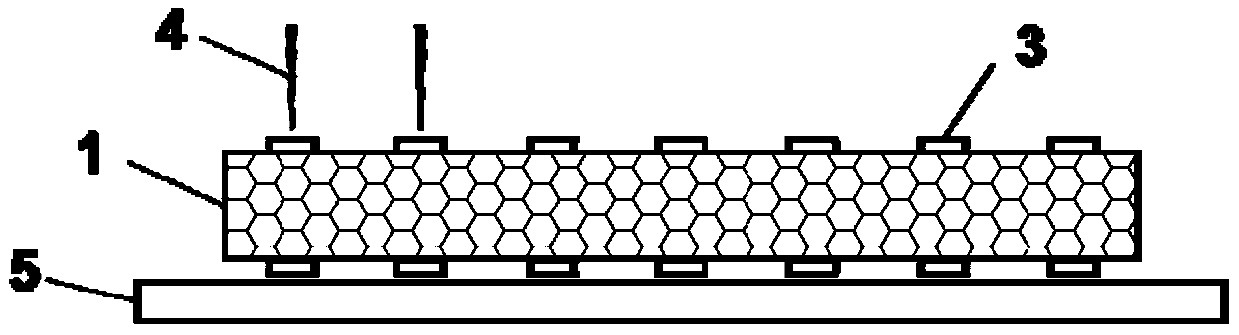

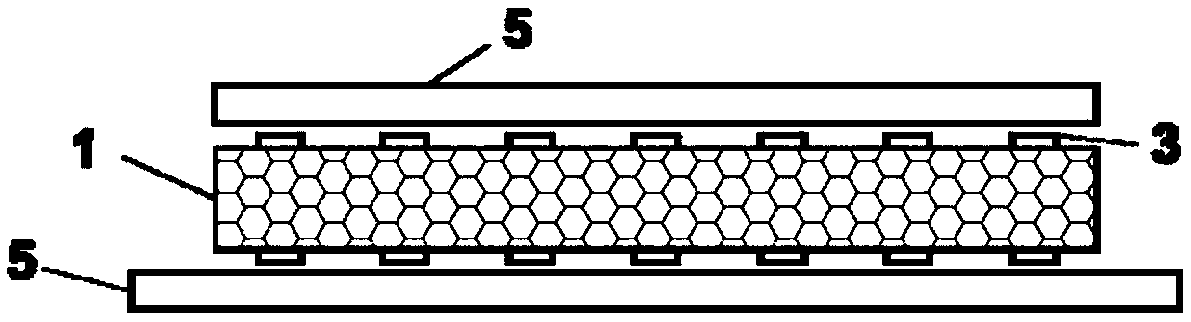

[0035] (2) Take the zinc oxide varistor sample obtained in step (1) as the base material, coat the upper and lower surfaces of the polished sample with photoresist, and use photolithography technology to transfer the shape and structure of the mask to the surface of the sample After the vacuum coating process, a plurality of micro silver electrodes with a thickness of 100 nanometers ...

Embodiment 2

[0043] According to the method for testing the uniformity of current distribution inside the varistor valve with a wide temperature range introduced in the patent specification of the present invention, the zinc oxide varistor valve was tested for the uniformity of current distribution. The specific process is as follows:

[0044] (1) For the thickness d=2mm, the upper and lower surface areas are each A=13.80mm 2 Polish the upper and lower surfaces of the zinc oxide varistor valve plate, so that the roughness of the upper and lower surfaces of the zinc oxide varistor valve plate is less than 1 micron;

[0045] (2) Take the zinc oxide varistor sample obtained in step (1) as the base material, coat the upper and lower surfaces of the polished sample with photoresist, and use photolithography technology to transfer the shape and structure of the mask to the surface of the sample After the vacuum coating process, a plurality of micro silver electrodes with a thickness of 100 nanometers ...

Embodiment 3

[0053] According to the method for testing the uniformity of current distribution inside the varistor valve with a wide temperature range introduced in the patent specification of the present invention, the zinc oxide varistor valve was tested for the uniformity of current distribution. The specific process is as follows:

[0054] (1) For the thickness d=2mm, the upper and lower surface areas are each A=13.78mm 2 Polish the upper and lower surfaces of the zinc oxide varistor valve plate, so that the roughness of the upper and lower surfaces of the zinc oxide varistor valve plate is less than 1 micron;

[0055] (2) Take the zinc oxide varistor sample obtained in step (1) as the base material, coat the upper and lower surfaces of the polished sample with photoresist, and use photolithography technology to transfer the shape and structure of the mask to the surface of the sample After the vacuum coating process, a plurality of micro silver electrodes with a thickness of 100 nanometers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com