Conduction angle calibration circuit for precision welding current measurement instrument

A current measuring instrument and precision welding technology, which is applied in the field of calibration circuits, can solve problems such as inapplicability, and achieve the effects of compact structure, improved load capacity, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings and embodiments.

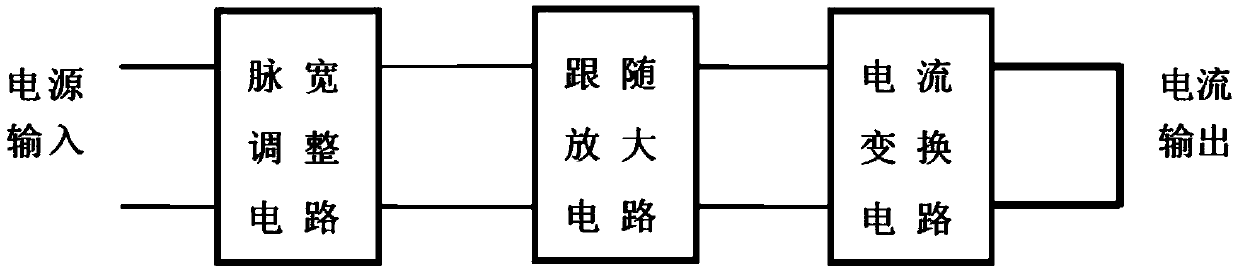

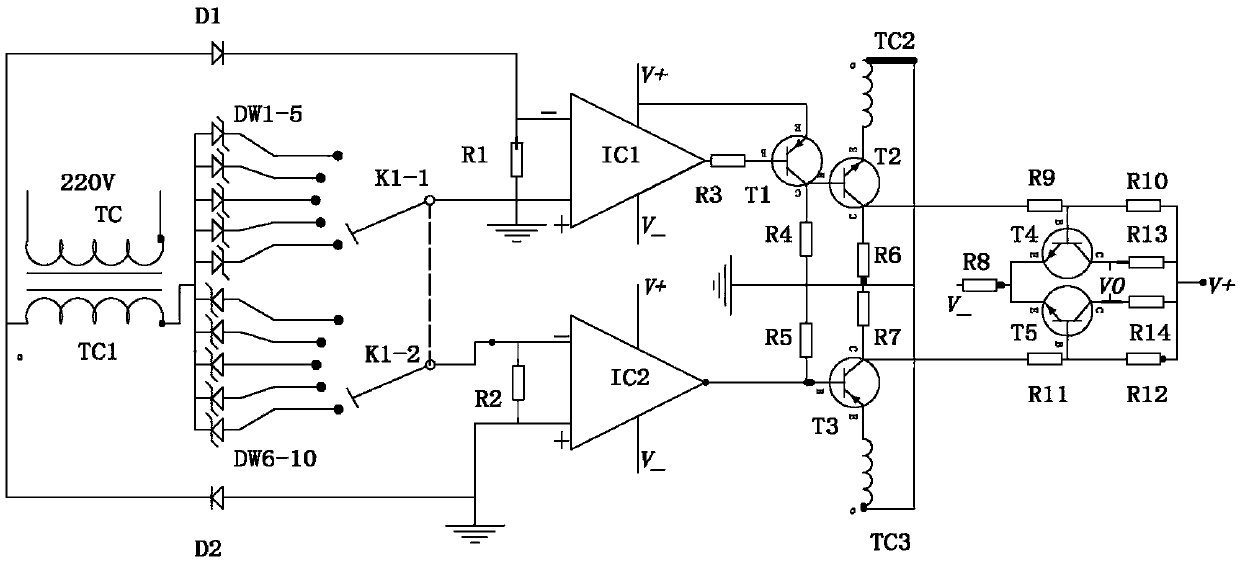

[0020] Such as figure 1 and image 3 As shown: in order to effectively calibrate the conduction angle measurement function of the precision welding current measuring instrument and realize accurate measurement of the precision welding current, the present invention includes a pulse width adjustment circuit with an adjustable pulse width on a fixed edge of the symmetrical axis and a pulse width adjustment circuit for improving A follower amplifier circuit with current pulse load capacity, the input end of the pulse width adjustment circuit is connected to the power supply, the output end of the pulse width adjustment circuit is connected to the input end of the follower amplifier circuit, and the output end of the follower amplifier circuit is connected to the current conversion circuit;

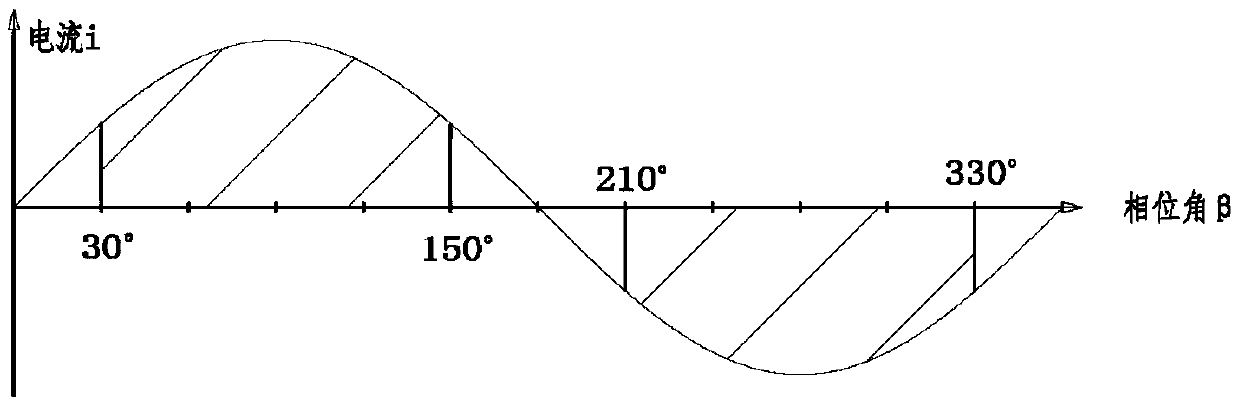

[0021] The pulse width adjustment circuit generates the current pulse wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com