Method for acquiring relative loss value of bonding surface of bonding lath

An acquisition method and bonding surface technology, which is applied in the field of quality inspection of laser-bonded crystal slabs, can solve problems such as lack of laser slabs, achieve the effects of improving measurement accuracy and stability, measuring accuracy, and reducing detection difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

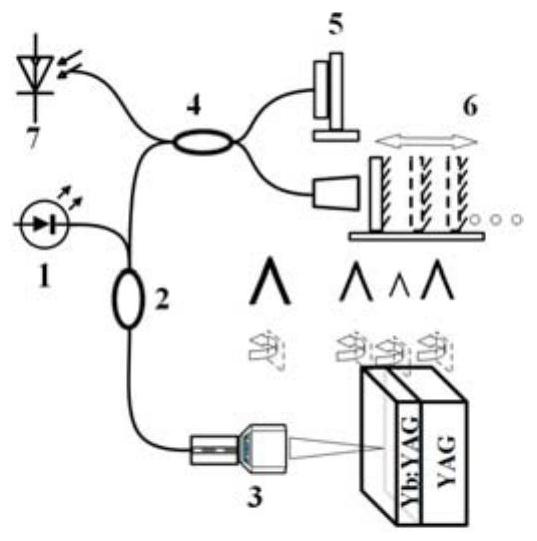

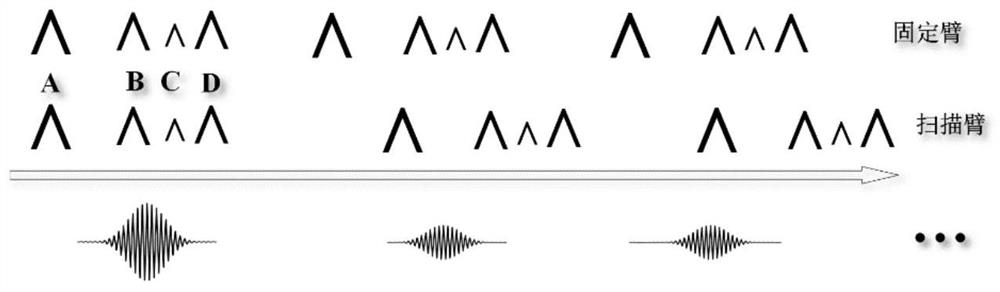

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] The present invention includes:

[0021] 1. Preliminary evaluation of the size, type, and absorption spectrum of the strip to be tested, and debugging of the interferometric system;

[0022] Clarify the measurement depth of the crystal to provide debugging standards for the scanning delay line; clarify the absorption spectrum of the doped part of the crystal, provide a reference when selecting the wavelength of the light source, and effectively avoid the absorption peak; clarify the bonding structure, including the number of bonding layers and the depth of the bonding surface Coarse positioning, this patent takes the common double-layer bonding structure as the research object, and does not carry out packaging, coating or integration.

[0023] 2. Use the white light interference system to test the standard reflective surface w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com