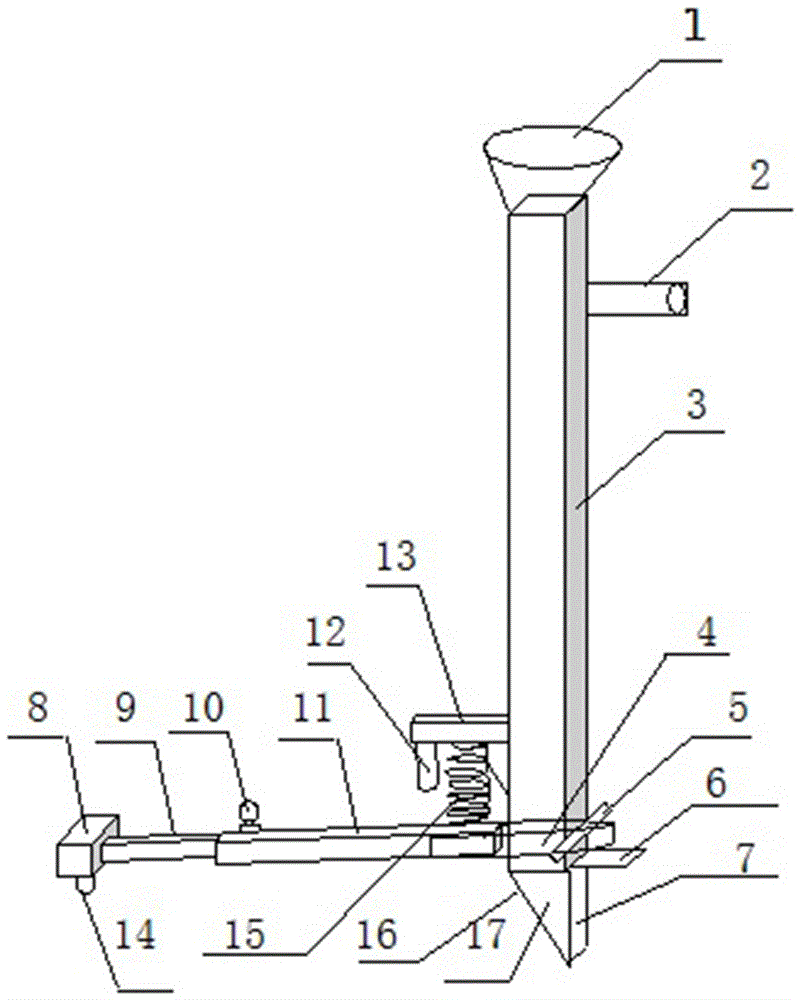

Precision corn seeder adopting one man operation

A single-man operation, precision seeder technology, applied in sowing, hole seeding, manual seeding tools, etc., can solve the problems of reduced performance and advantages, laborious use, poor group uniformity, etc., to achieve high seeding quality and operation efficiency. , Precise control of broadcast depth, flexible and lightweight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

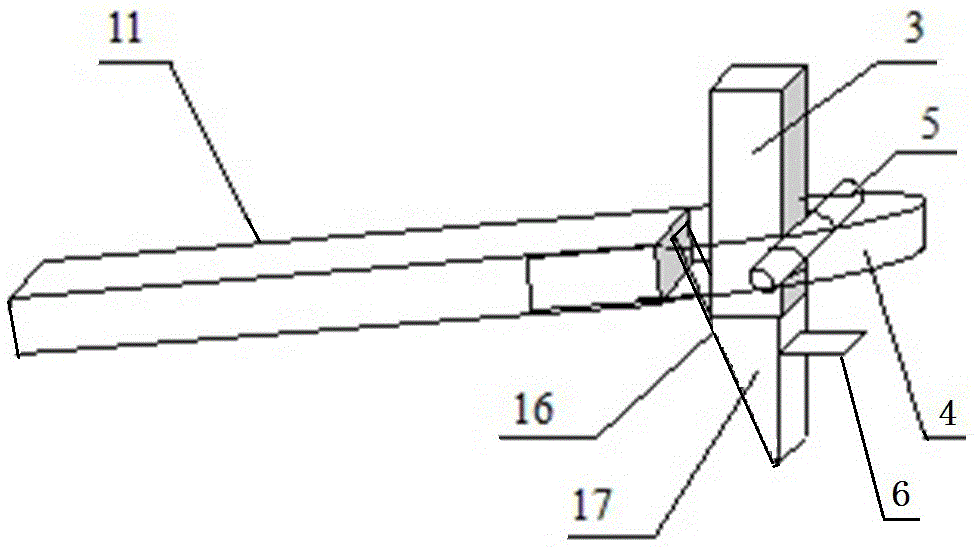

[0011] The seed-throwing box (1) of the seed conduit device is made into a bowl shape by a thick iron sheet, and the lower opening is welded with the upper edge of the seed conduit (3), and the seed conduit (3) is a square steel pipe. The front support rod (8) of the plant spacing adjustment device is a square steel pipe, which is welded to the front end of the inner tube (9) for plant distance adjustment. The spacing between the plants is adjusted in the inner pipe (9) and the outer tube (11) is a square steel pipe, and the fastening screw (10) is installed in the distance between the plants and the outer tube (11) front. The distance between plants is adjusted and the outer pipe (11) rear end is welded with the upper end of the front baffle plate (16) of the sowing port earlier, and then links to each other with the inboards of the two arms of the U-shaped connecting piece (4). The U-shaped connecting piece (4) is sleeved on the seed conduit (3), and its arc-shaped two sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com