A pulverizer with multi-stage pulverization function

A pulverizer and secondary crushing technology, applied in the field of agricultural machinery, can solve the problems of high production cost and labor cost, low work efficiency, and single function, and achieve the effect of low purchase cost, small selectivity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

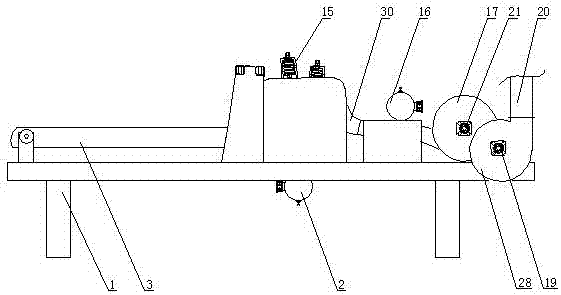

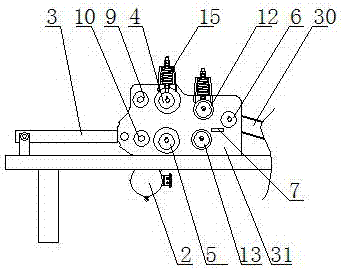

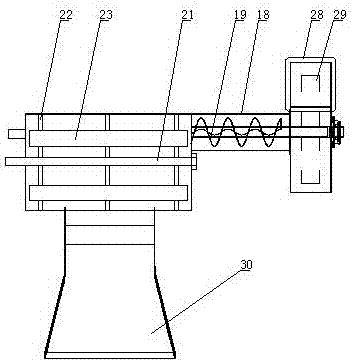

[0029] The pulverizer with multi-stage crushing function includes a frame 1, a primary crushing device and a secondary crushing device. The primary crushing device is installed on one side of the frame 1, and the secondary crushing device is installed on the other side of the frame 1. The first-stage crushing device is composed of a primary crushing motor 2, a conveyor belt 3, an upper pre-press crushing roller 4, a lower pre-press crushing roller 5, a crushing hob 6 and a crushing fixed knife 7; An upper pre-compression crushing roller 4 and a lower pre-compression crushing roller 5 are installed. The circumferential surfaces of the upper pre-compression crushing roller 4 and the lower pre-compression crushing roller 5 are regularly provided with bucket-shaped pre-compression crushing teeth 8 .

[0030] The front ends of the upper pre-compression crushing roller 4 and the lower pre-compression crushing roller 5 pass through the installation plate 31 to form an up-and-down sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com