Granular bioretention facility medium layer filler prepared from tap water plant residual mud

A water plant, bioretention technology, applied in water pollutants, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of high cost, permeability does not meet the requirements of subsurface wetlands, zero permeability And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

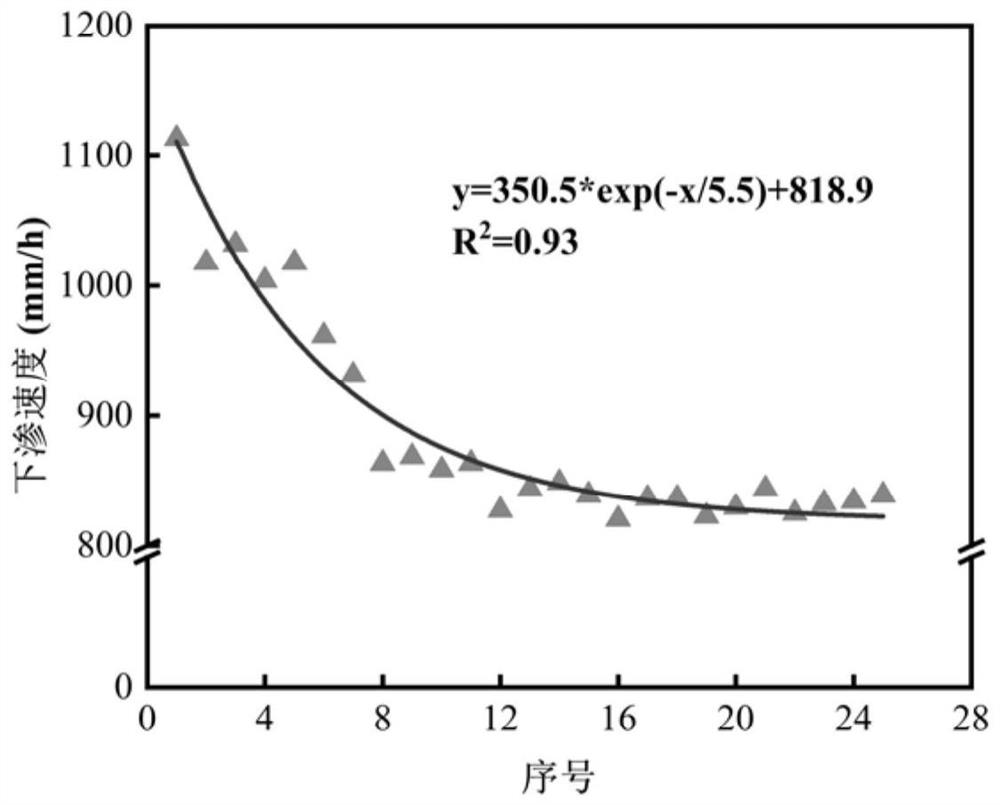

Embodiment 1

[0043] Embodiment 1 A kind of granular bioretention facility media layer filler made from waterworks sludge

[0044] S1: 50% composition, 3% chitosan oligosaccharide, 2% pullulan, 5% trehalose, 8% glucosamine, 4% lactic acid, 1.5% potassium chloride, 1% magnesium sulfate and 25.5% pure The bio-curing agent composed of water was diluted with pure water at a ratio of 1:200, and then the bio-curing agent diluted with pure water was sprayed at a ratio of 1.6% in the tap water long sludge that had not been dehydrated and dried, and the humidity was relatively low. High, when the moisture content of the remaining sludge is about 80%, mix evenly with a sludge treatment mixer to get a mixture 1; the composition is 60% polyoxyethylene fatty alcohol ether and 40% α-amylase ;

[0045] S2: by using a low-temperature heat pump oven for dehydration and drying, the moisture content of the mixture 1 in step S1 is reduced to less than 40%, and the mixture 2 is obtained;

[0046] S3: Send the...

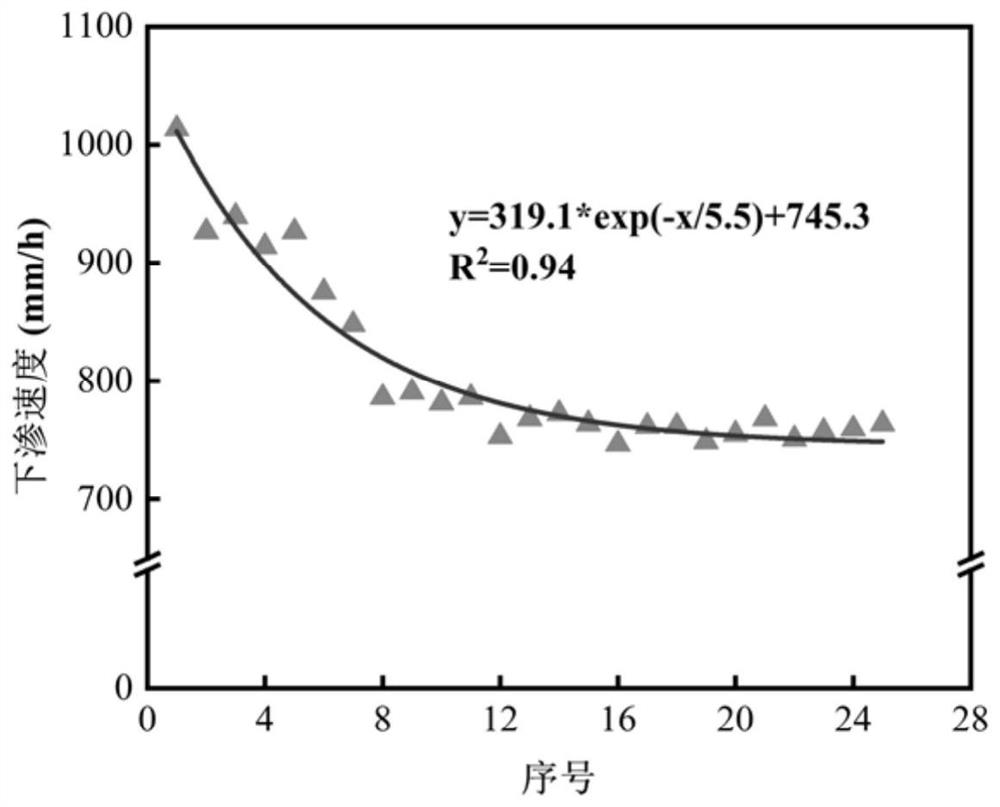

Embodiment 2

[0048] Embodiment 2 A kind of granular bioretention facility medium layer filler made of waterworks sludge

[0049] S1: 46% composition, 2.7% chitosan oligosaccharide, 1.8% pullulan, 4.6% trehalose, 7.7% glucosamine, 3.8% lactic acid, 1.5% potassium chloride, 1% magnesium sulfate and 30.9% pure The biological curing agent composed of water was diluted with pure water at a ratio of 1:200, and then the biological curing agent diluted with pure water was sprayed at a ratio of 2% on tap water sludge that had not been dehydrated and dried. High, when the moisture content of the remaining sludge is about 80%, mix evenly with a sludge treatment mixer to get a mixture 1; the composition is 60% polyoxyethylene fatty alcohol ether and 40% α-amylase ;

[0050] S2: by using a low-temperature heat pump oven for dehydration and drying, the moisture content of the mixture 1 in step S1 is reduced to less than 40%, and the mixture 2 is obtained;

[0051] S3: Send the mixed material 2 obtaine...

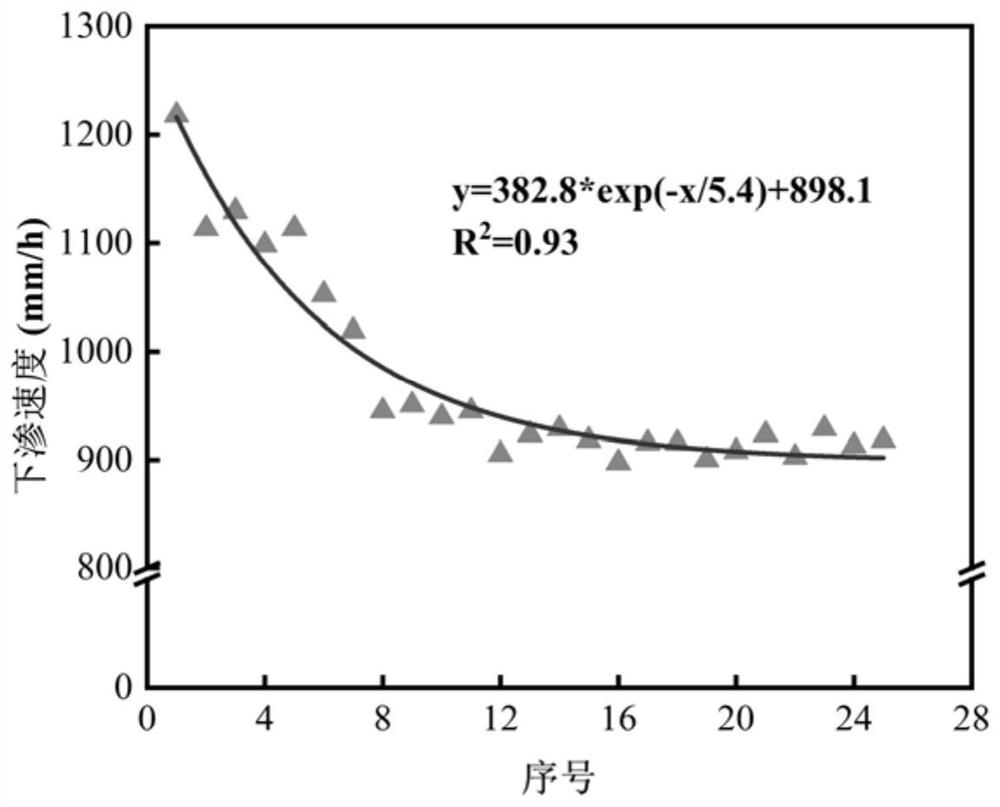

Embodiment 3

[0053] Example 3 A granular bioretention facility media layer filler made from waterworks sludge

[0054] S1: 53% composition, 3.4% chitosan oligosaccharide, 2.1% pullulan, 5.2% trehalose, 8.2% glucosamine, 4.1% lactic acid, 1.5% potassium chloride, 1% magnesium sulfate and 21.5% pure The bio-curing agent composed of water was diluted with pure water at a ratio of 1:200, and then the bio-curing agent diluted with pure water was sprayed at a ratio of 2.5% in the tap water long sludge that had not been dehydrated and dried, and dried in a relatively humid environment. High, when the moisture content of the remaining sludge is about 80%, mix evenly with a sludge treatment mixer to get a mixture 1; the composition is 60% polyoxyethylene fatty alcohol ether and 40% α-amylase ;

[0055] S2: by using a low-temperature heat pump oven for dehydration and drying, the moisture content of the mixture 1 in step S1 is reduced to less than 40%, and the mixture 2 is obtained;

[0056] S3: S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com