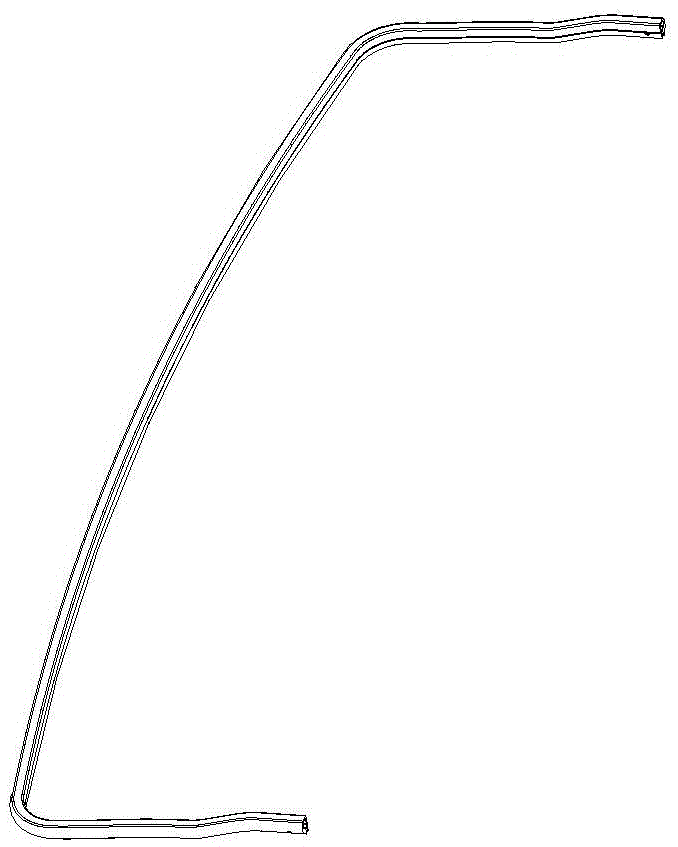

Integral molding device for upper edging of skylight wind blocking net

A molding device and windshield net technology, which is applied in transportation and packaging, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of difficult positioning, long processing cycle, and easy-to-leave processes, and achieve good product consistency and save The effect of removing intermediate processes and reducing intermediate inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

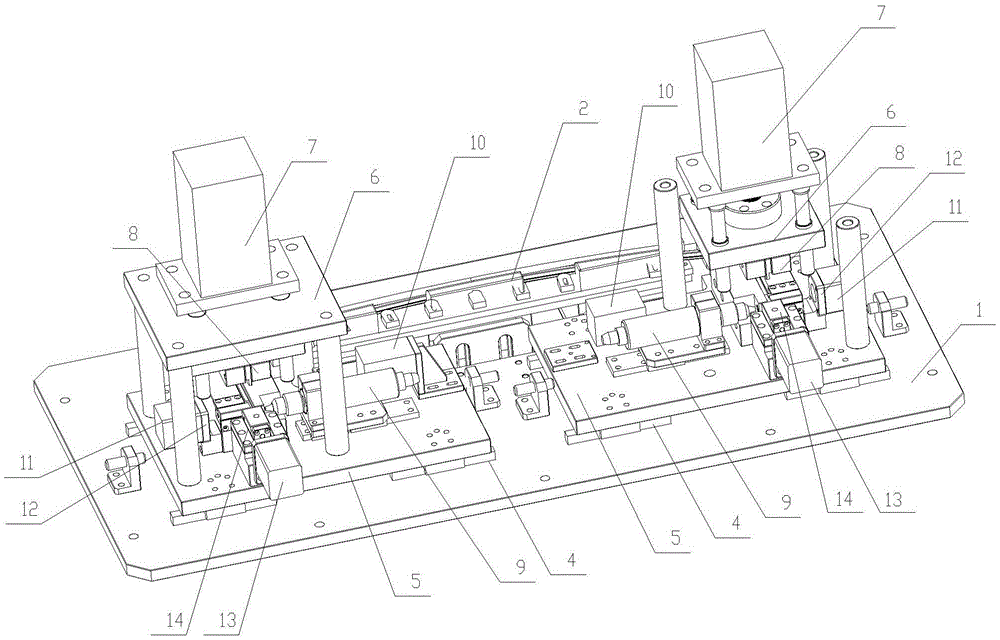

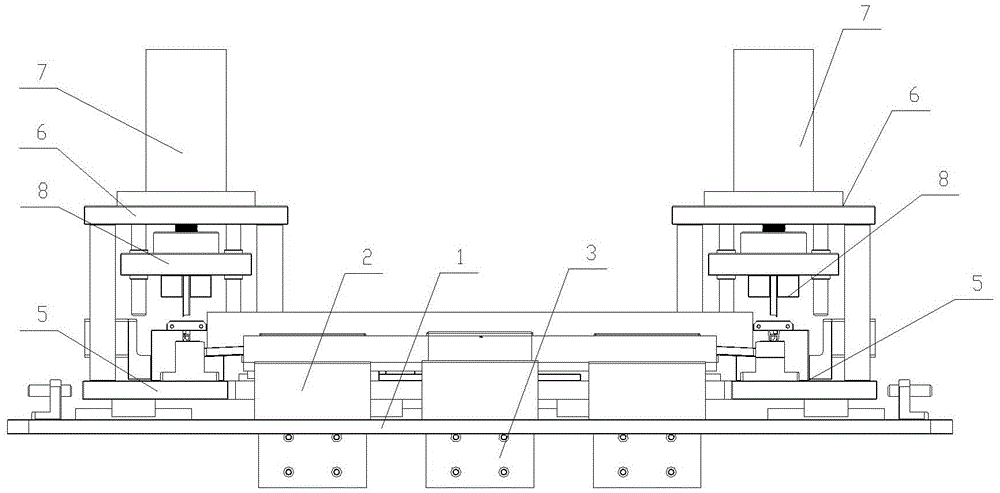

[0010] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] like Figure 2-3 As shown, an integrated forming device for the side strips of the skylight windshield, including a mounting base 1, three middle forming modules 2 distributed in a straight line are movable on the mounting base 1, and top bending grooves are provided on the middle forming module 2. The seat 1 is provided with three upper cylinders 3 that respectively drive the three middle forming modules 2 to move upward, and the upper surface of the mounting seat 1 is provided with slide rails 4 arranged along the arrangement direction of the middle forming modules 2 on both sides. Sliding seats 5 are provided, two sliding seats 5 are provided with installation frames 6 respectively, and the mounting frames 6 are provided with a press-down oil cylinder 7, and the end of the piston rod of the press-down oil cylinder 7 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com