Connection structure between transmission shaft and vehicle body of a front-rear drive vehicle

A technology of front and rear drive and connection structure, which is applied in the direction of control devices, vehicle parts, transportation and packaging, etc., which can solve the problem of high strength and rigidity performance requirements of the connection structure, complex structure of the bracket assembly of the body assembly, and unfavorable light weight Vehicle cost control and other issues, it is easy to meet the stiffness performance requirements, improve fuel economy, and improve NVH performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

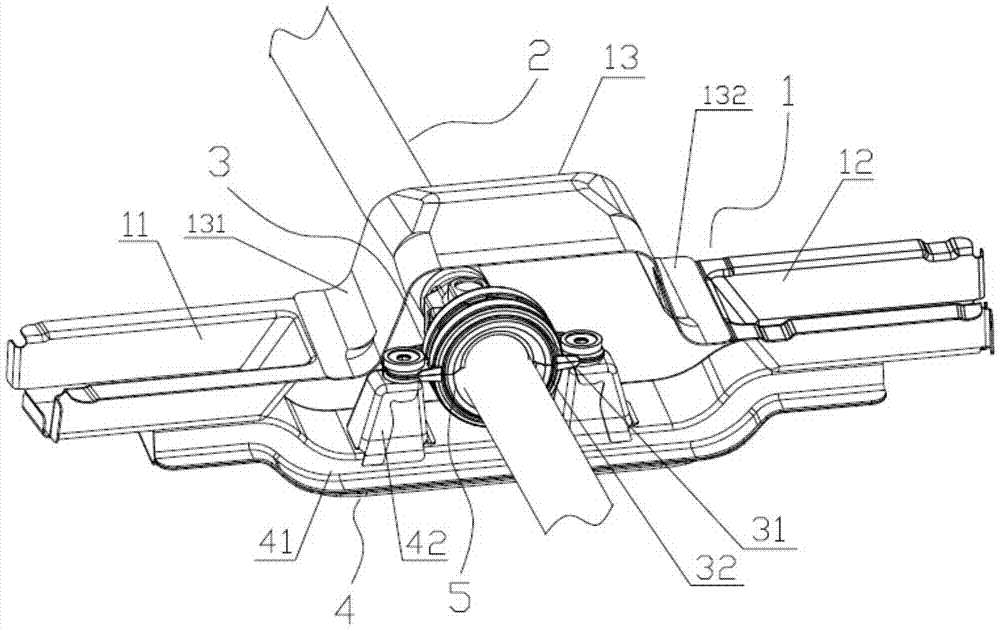

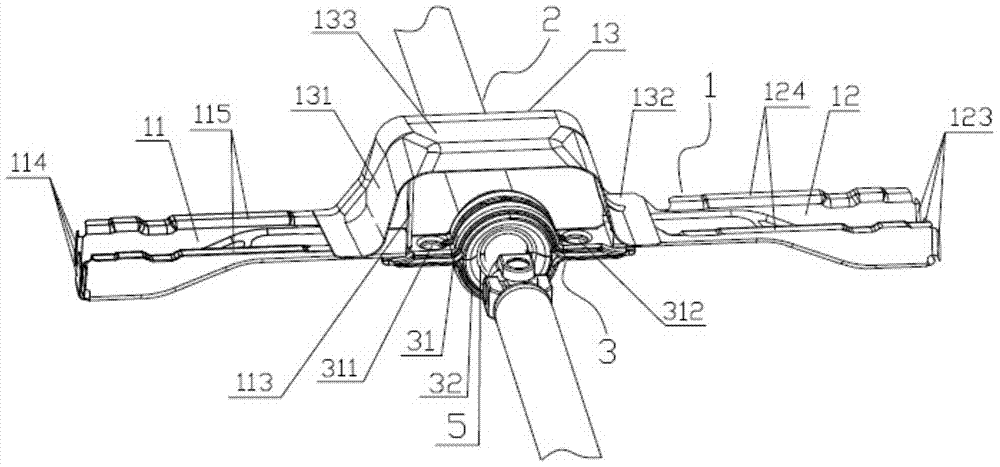

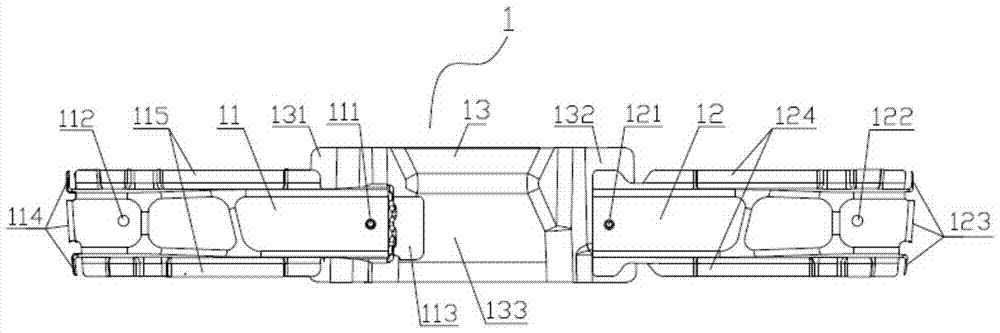

[0020] Such as Figure 2 to Figure 5 The connection structure between the drive shaft and the vehicle body of the front-rear drive vehicle shown includes the body main body connection bracket 1 and the transmission shaft support frame 3. Shaped left mounting beam 11 and a U-shaped right mounting beam 12 in section form. The outer surface of the left flange 131, the outer surface of the top 133 and the outer surface of the right flange 132 of the "J"-shaped structure of the crossbeam connector 13 are welded to the front floor channel.

[0021] The left end of the left mounting beam 11 has a first left welding flange 114 welded with the left longitudinal beam of the vehicle body, and the upper front and rear sides of the left mounting beam 11 have a second left welding flange 115 welded with the left floor panel. The right end of the second left welding flange 115 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com