Powder metallurgy cam and preparation method thereof

A powder metallurgy and cam technology, applied in the field of powder metallurgy cam and its preparation, can solve the problems of poor cam dimensional accuracy, increase in production cost, increase equipment investment, etc., and achieve reduction in production cost, equipment investment, and energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

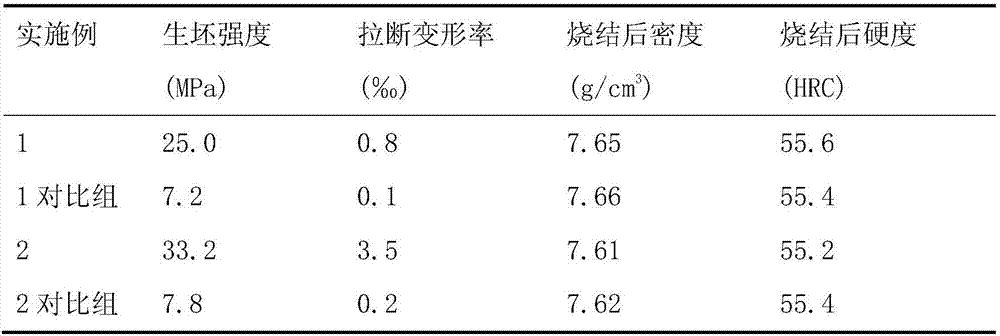

Examples

Embodiment 1

[0021] A kind of powder metallurgy cam and the preparation steps of the camshaft prepared from this cam are as follows:

[0022] (1) Put 97.0% ASTALOY-E alloy powder, 2.0% graphite and 1.0% epoxy resin powder into the mixer, and take it out after mixing for 2 hours;

[0023] (2) Put the uniformly mixed powder in step (1) into a mold for molding, the molding pressure is 450MPa, take it out after pressing, and obtain the cam green body;

[0024] (3) The green body obtained in step (2) is placed in a blast drying oven for curing, and the curing temperature is 120° C.,

[0025] (4) The solidification time is 120min, cool down with the furnace, and take out;

[0026] (5) Assembling the solidified green body obtained in step (3) into a shaft on a camshaft assembly machine, the assembly interference is 0.04 mm;

[0027] (6) Put the camshaft obtained in step (4) into a vacuum sintering furnace for high-temperature calcination at a temperature of 1098°C for 2 hours. After cooling, ta...

Embodiment 2

[0029] A powder metallurgy cam and a camshaft prepared from the cam, the preparation steps are as follows:

[0030] (1) 1.5% epoxy resin and 0.5% polyurethane are dissolved in ethyl acetate to obtain binder solution;

[0031] (2) Put 84.0% (mass fraction, the same below) atomized iron powder, 3.0% copper powder, 3.0% graphite, 6.0% ferrochromium, and 2.0% ferrophosphorus into the mixer, pre-mix for 0.5 hours, and spray Add the binder solution in the same way, dry while mixing, and finally get a uniformly dry bonding powder;

[0032] (3) Put the uniformly mixed powder in step (2) into a mold for compression molding, the molding pressure is 600MPa, take it out after compression, and obtain the cam green body;

[0033] (4) Place the green body obtained in step (3) into a blast drying oven to solidify, the solidification temperature is 120° C., and the solidification time is 150 min. Cool with the furnace and take it out;

[0034] (5) Assembling the solidified green body obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com