Method for welding special-shaped flange pipelines and welding tool

A flanged pipe and special-shaped technology, which is applied in the pipeline installation method and tooling field, can solve the problems of difficulty in ensuring assembly quality, inability to produce multiple pieces in a centralized manner, and non-interchangeability of exhaust gas outlet pipes, etc., so as to improve production efficiency, Realize direct assembly and ensure the effect of installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

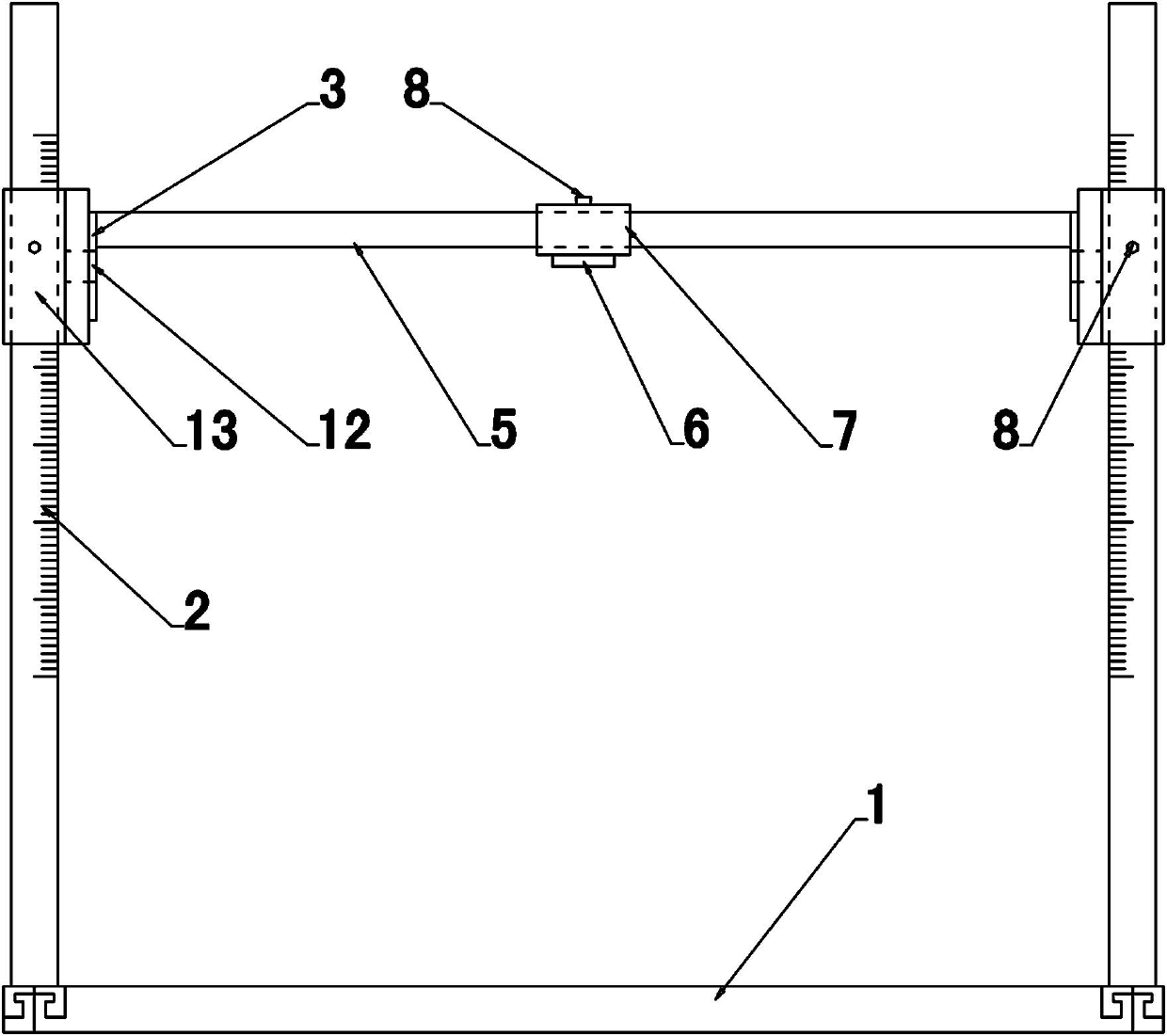

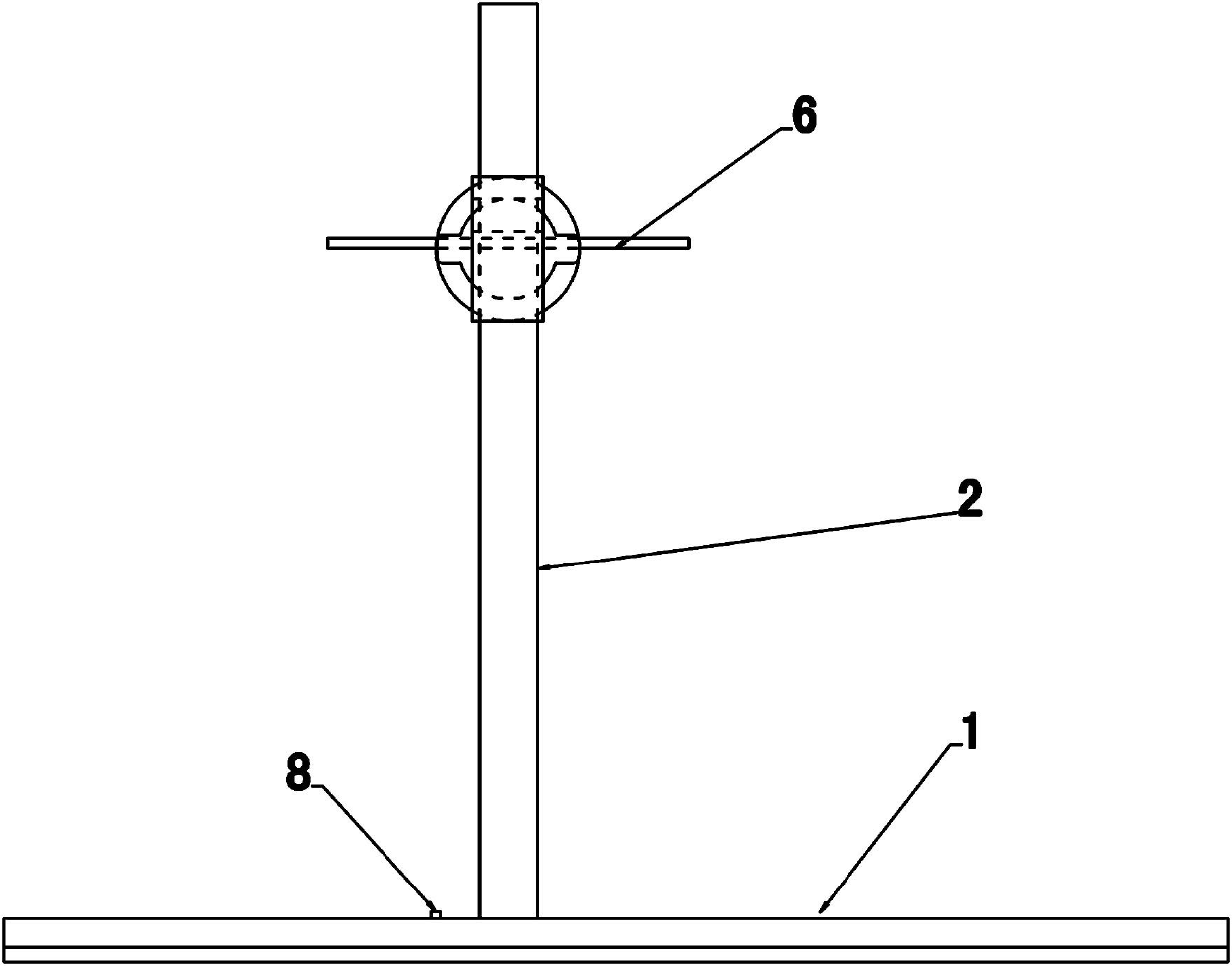

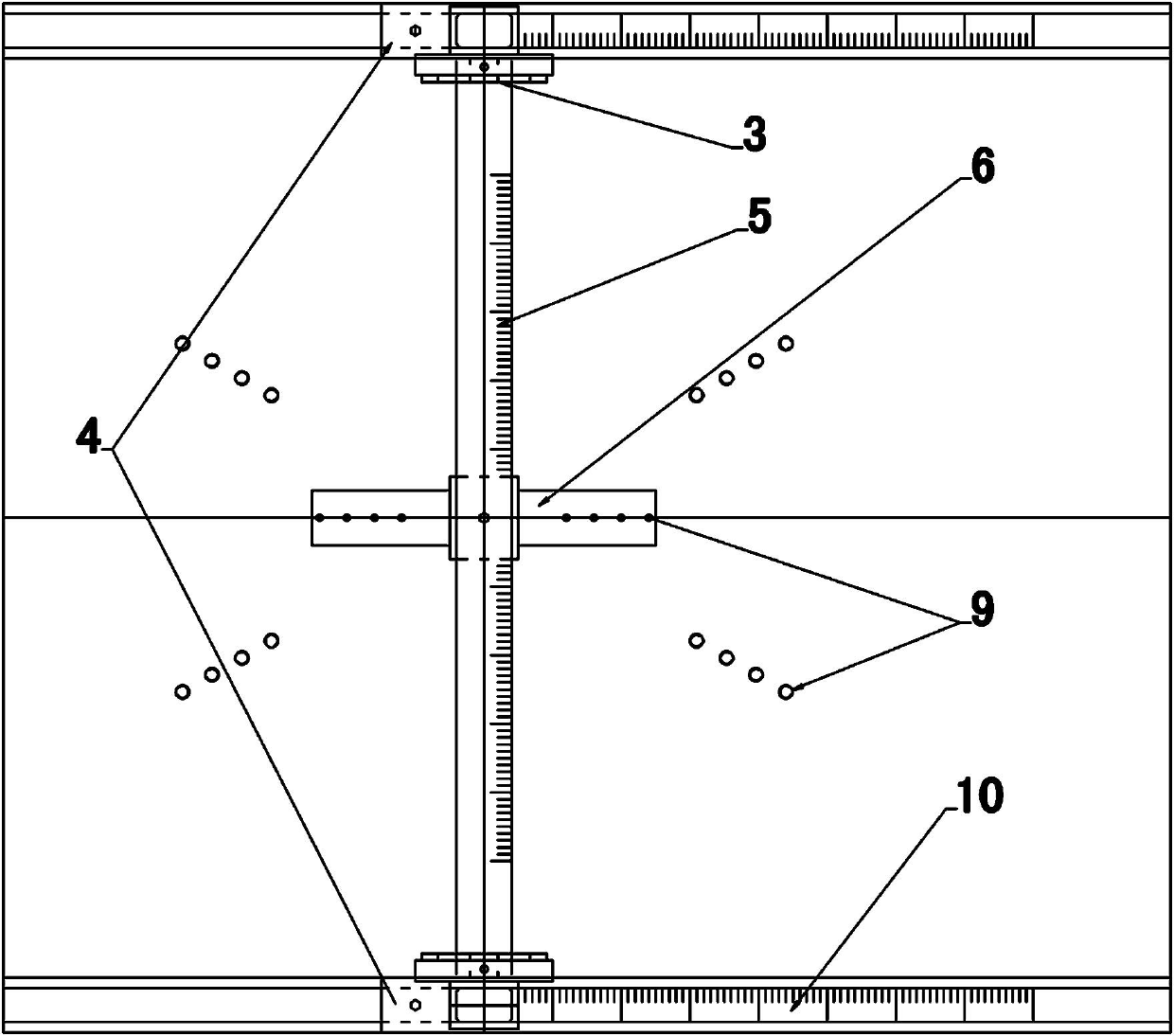

[0025] like Figure 4 , 5 As shown in , a special-shaped flange pipeline welding method includes the following steps:

[0026] 1. The steps of 3D simulation assembly with software;

[0027] In this example, the exhaust gas outlet pipe of a low-speed diesel engine supercharger is taken as an example. Generally, in the process of on-site matching and welding, it is often found that the exhaust gas outlet pipe made according to the drawing does not match the actual size during assembly. Repair or on-site measurement methods to solve. In the present invention, on the premise of ensuring the blueprints of the low-speed diesel engine type, supercharger type, exhaust pipe, and scavenging box, CAD software is used to perform three-dimensional simulation assembly, and theoretically check whether each component can be assembled correctly.

[0028] Find out the factors affecting the assembly of the exhaust gas outlet pipe according to the three-dimensional model diagram. If you want ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com