Feeding rack cart with adjustable height

A material rack and cart technology, which is applied in the direction of trolleys, multi-axis trolleys, lifting frames, etc., can solve the problems of affecting positioning accuracy, easy overturning during handling, and high labor intensity, and achieves reduced impact, convenient operation, and reduced work intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

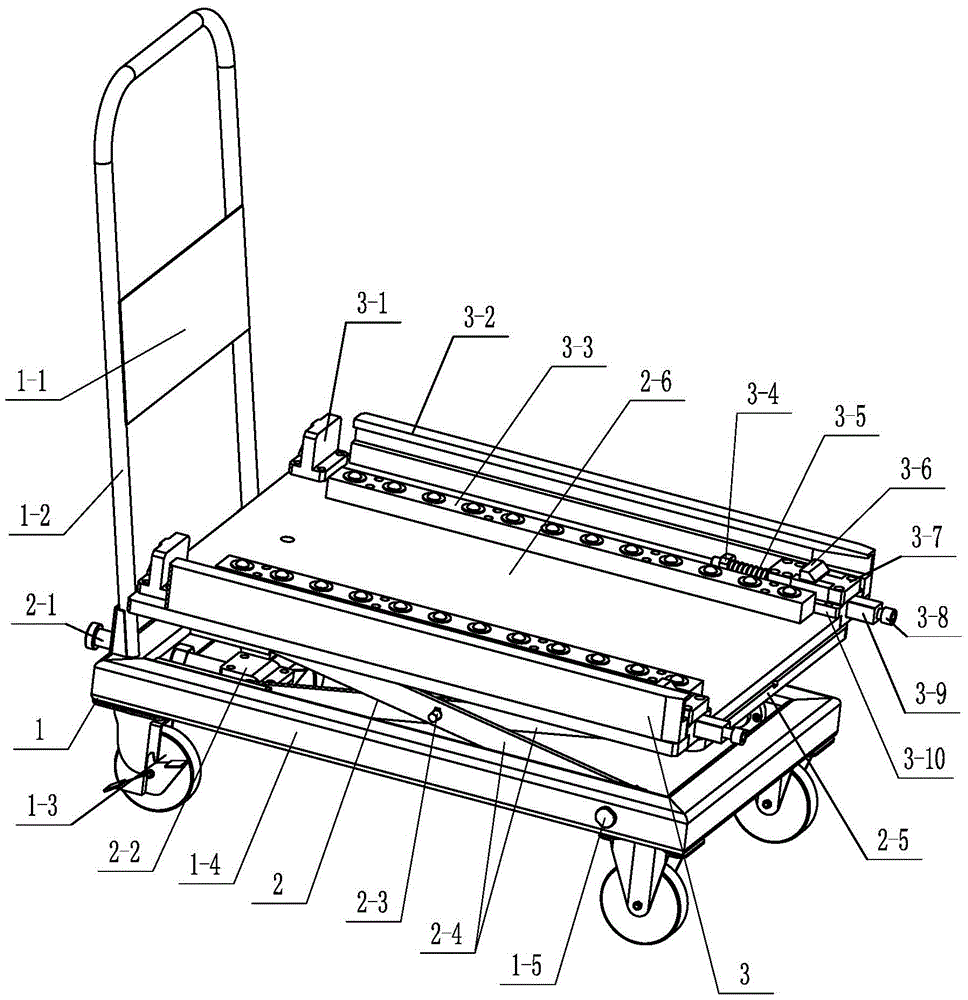

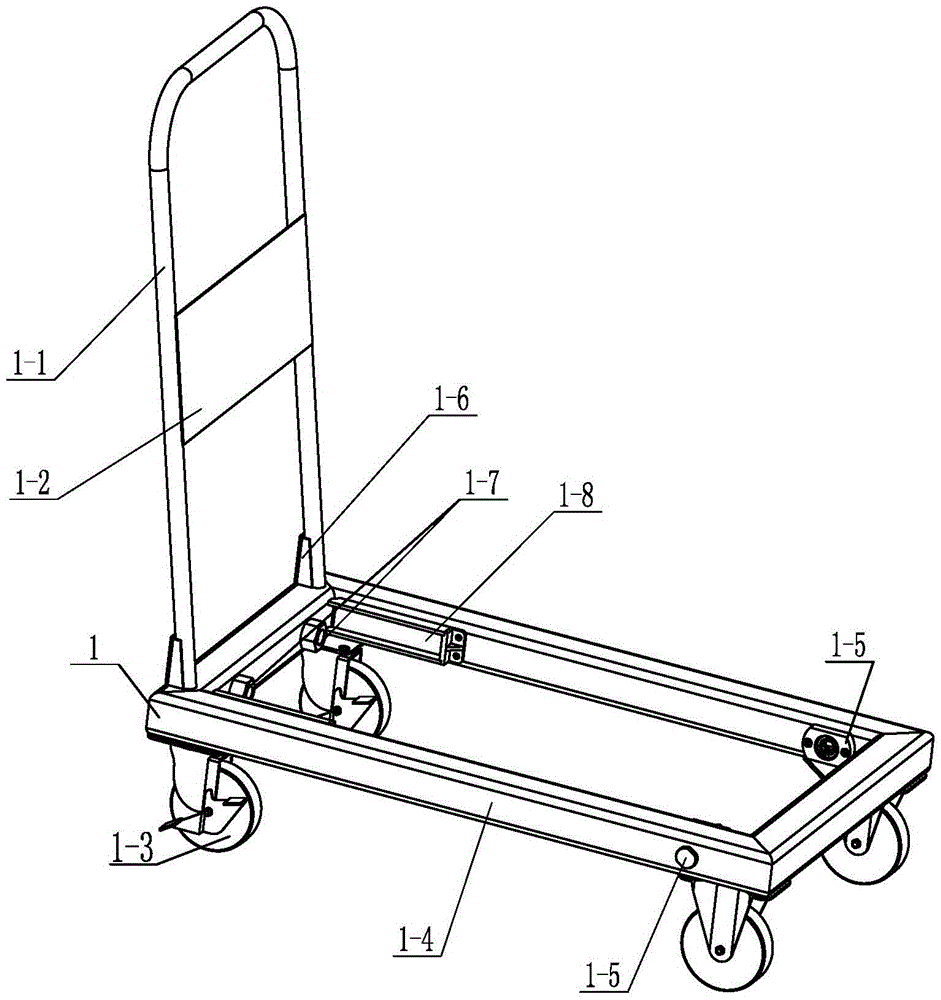

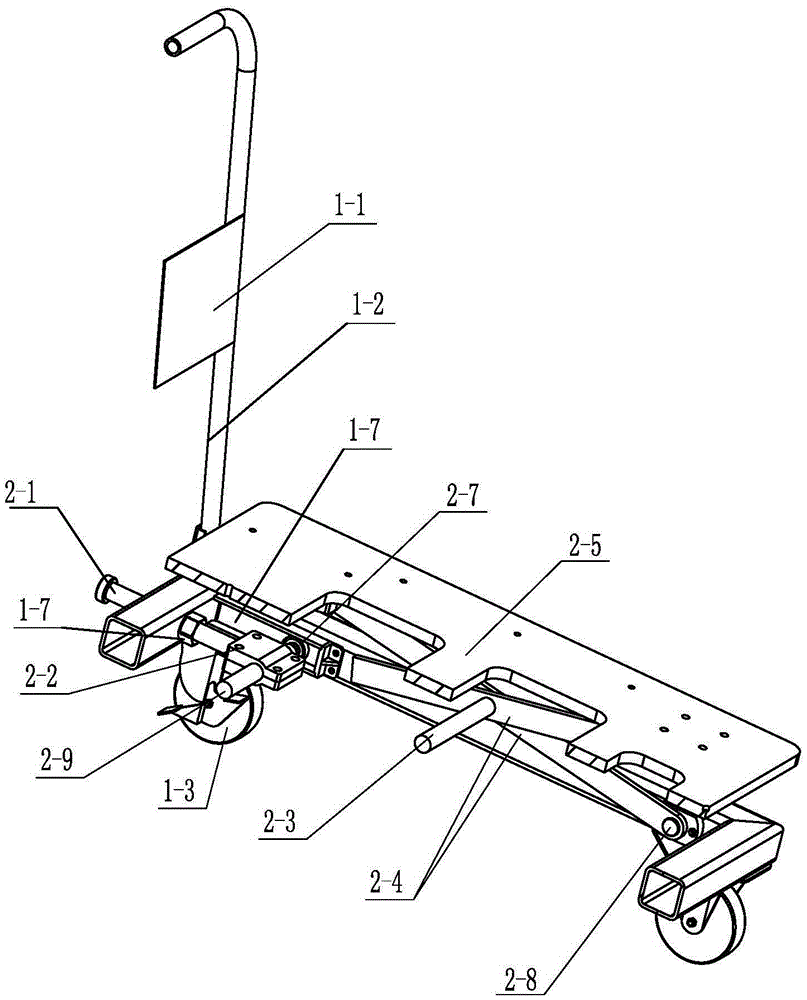

[0021] See Figure 1~3 As shown, the height-adjustable feeding rack trolley of the present invention includes a mobile trolley 1, and the mobile trolley 1 frame includes a vehicle frame 1-4 formed by two beams and two longitudinal beams welded and connected to the bottom of the vehicle frame 1-4. four casters 1-3, the rear end of vehicle frame 1-4 has handrail 1-2, beam and longitudinal beam of the present invention can adopt rectangular steel pipe, and welding forms vehicle frame 1-4, and four casters 1-3 are installed on The lower part of the vehicle frame 1-4, the caster 1-3 can be a heavy-duty caster, and the caster 1-3 installed at the rear has a braking mechanism, which is convenient for the operator to stop and brake. The present invention is on the handrail 1-2 A reinforcing plate 1-1 is fixed, and reinforcing ribs 1-6 are welded between the vehicle frame 1-4, the handrail 1-2 and the longitudinal beam and crossbeam of the vehicle frame 1-4, so that the trolley can bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com