Auxiliary tooling for coating the edge sealant of the lower pound column reinforcement sheet of passenger-to-cargo aircraft

A technology of edge sealing and auxiliary tooling, which is applied in the directions of transportation and packaging, sending objects, thin material processing, etc., can solve the problems of uneven pasting gaps and low work efficiency, and achieve the effect of improving pasting efficiency and pasting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

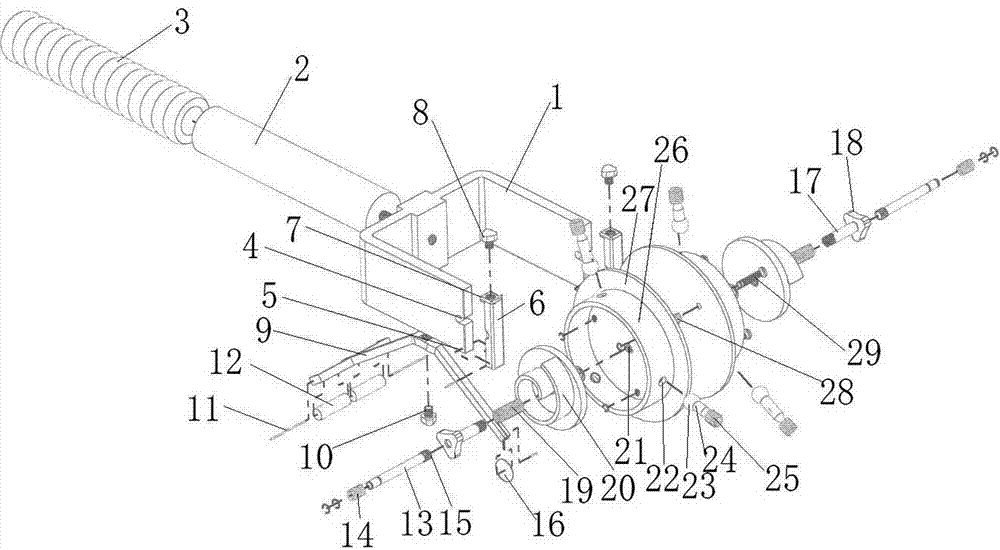

[0018] Attached below figure 1 The present invention will be further described.

[0019] An auxiliary tooling for applying sealant to the edge of the lower pound column reinforcement of a passenger-to-cargo aircraft, including: a bracket 1; several pairs of tape fixing rings 26 coaxially arranged, and a gap adjustment is arranged between the two tape fixing rings 26 of each pair device, each tape fixing ring 26 is rotatably installed in the bracket 1 through the central shaft 13 connected coaxially; the tracking wheel 16 is rotatably mounted on the lower end of the tape fixing ring 26, and its rotation axis is parallel to the axis of the central shaft 13; And the tape fixing device is arranged on the tape fixing ring 26 and is used for fixing the inner ring of the tape inserted on the tape fixing ring 26 . During use, the adhesive tape is fixed on the adhesive tape fixing ring 26 through the adhesive tape fixing device, and then the gap between the two inner ferrules of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com