Multi-station all-in-one machine used for brewing wine

An integrated workstation technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of increasing the work intensity of operators and affecting the efficiency of wine production, and achieve the effect of improving the efficiency of wine production and preventing mutual interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

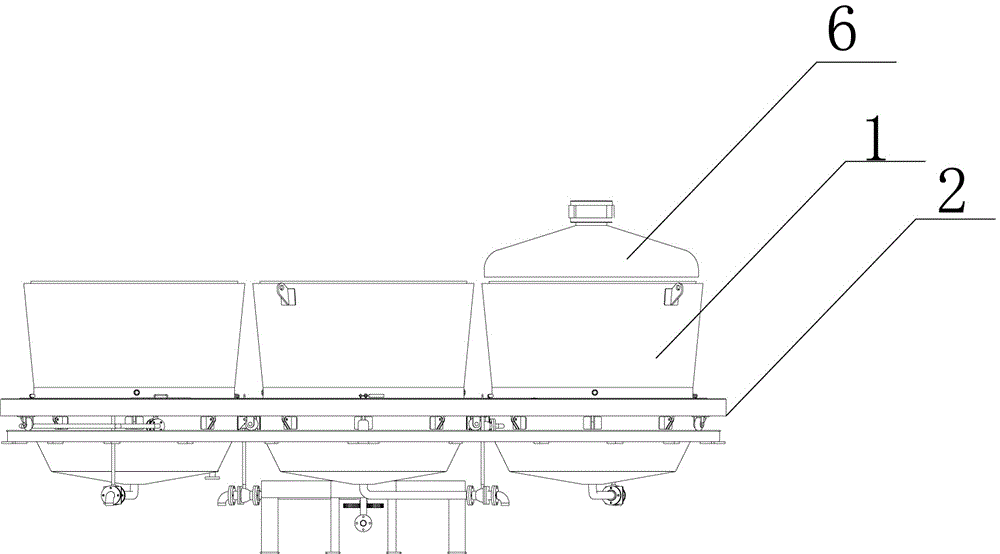

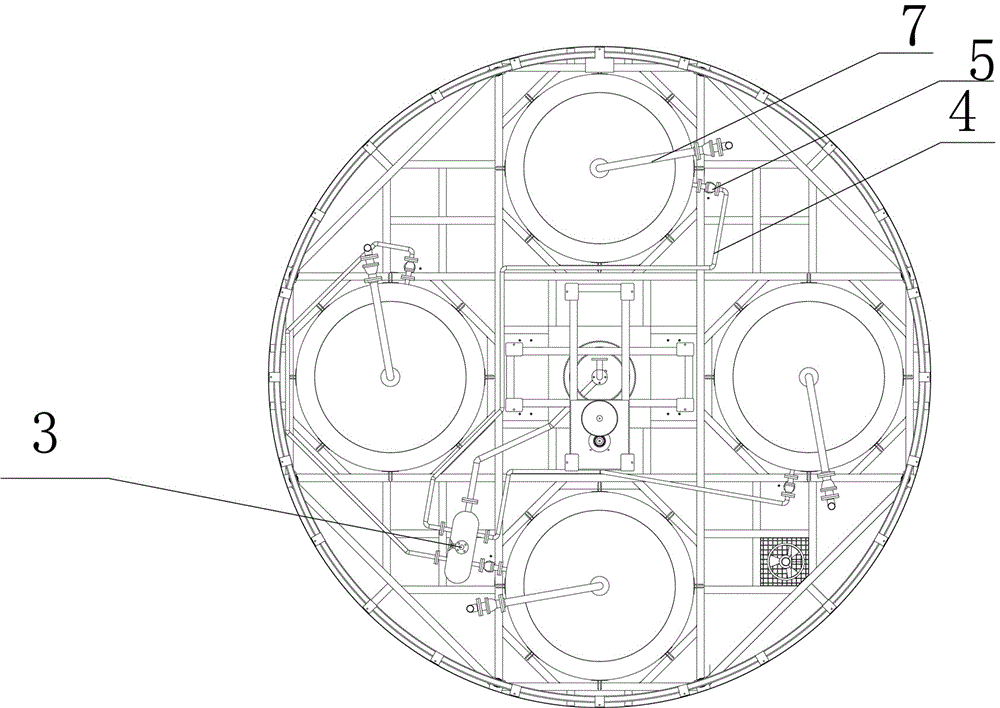

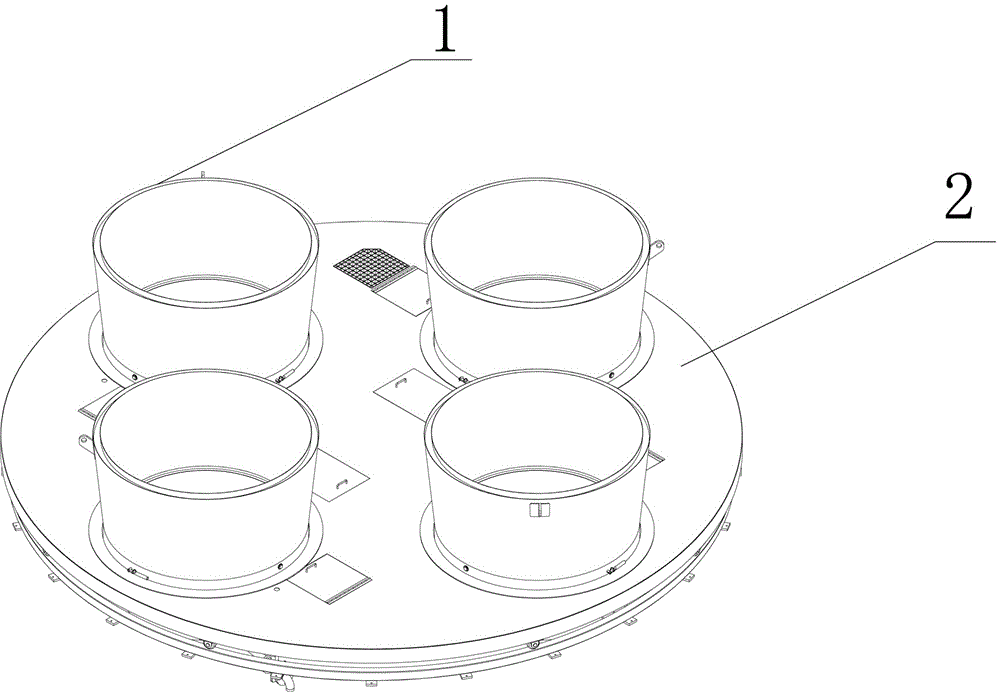

[0022] Such as figure 1 , 3 Among them, a multi-station all-in-one machine for wine making includes a rotating body, the rotating body is a rotating disk 2, four processing positions 1 (also can be two processing positions 1, or three processing positions 1, or more A plurality of processing bays 1) are equidistantly arranged on the rotating disk 2, and the first driving device drives the rotating disk 2 to rotate in a circle around its central axis, and the processing bays 1 on the rotating disk 2 are driven by the first driving device to rotate The central axis of disc 2 rotates in a circle, and the processing cabin 1 rotates the central axis of disc 2 in a circular motion. The fixed trajectory is composed of four segmented trajectories, corresponding to mixing, fermentation, first steaming, and second steaming respectively. For wine, each segmented trajectory is the trajectory formed by the rotation of the rotating disk 2 by 90 degrees, that is, the processing bay 1 enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com