Time-adjustable warp tension control device of loom

A tension control and warp technology, which is applied in looms, textiles, dobby machines, etc., can solve the problems of unrealistic tension duration, complicated debugging, and high equipment cost, so as to restore normal tension, increase warp let-off, and mechanism simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

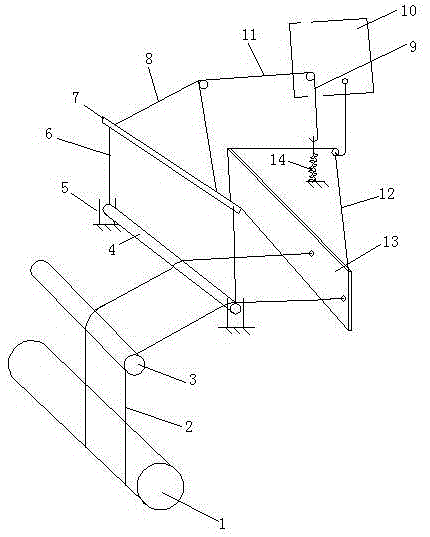

[0019] Such as figure 1 As shown, a time-adjustable loom warp tension control device includes warp beam 1, warp yarn 2, back rest 3, tension rod 4, guide groove 5, tension rod lifting rope 6, guide roller 7, guide roller lifting rope 8 , heald hook 9, lifting arm 10, heald arm 11, heald frame lifting rope 12, heald frame 13 and spring 14.

[0020] The warp yarn 2 is wound on the warp beam 1, and a tension rod 4 is installed on the loom backrest 3 and the heald frame 13 for wearing the warp yarn, and the warp yarn 2 that needs to be foamed and wrinkled bypasses the tension rod 4 and penetrates the heald frame 13 The inner healds are combined with other warp yarns to form a warp yarn system and interweave weft yarns.

[0021] The tension rod 4 is installed in the guide groove 5 , a tension rod lifting rope 6 is connected to each of the two ends of the tension rod 4 , and the other end of the tension rod lifting rope 6 is connected to the guide roller 7 . The lifting arm 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com