A vertical simulation device and simulation method for submarine oil spill

A simulation device and vertical technology, applied in measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of being unable to provide technical support for decision-making on emergency response to marine oil spills and other pollutants, and being unable to measure and observe oily media. , to achieve the effects of avoiding the decline of observation and shooting effects, improving clarity, and simplifying the process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

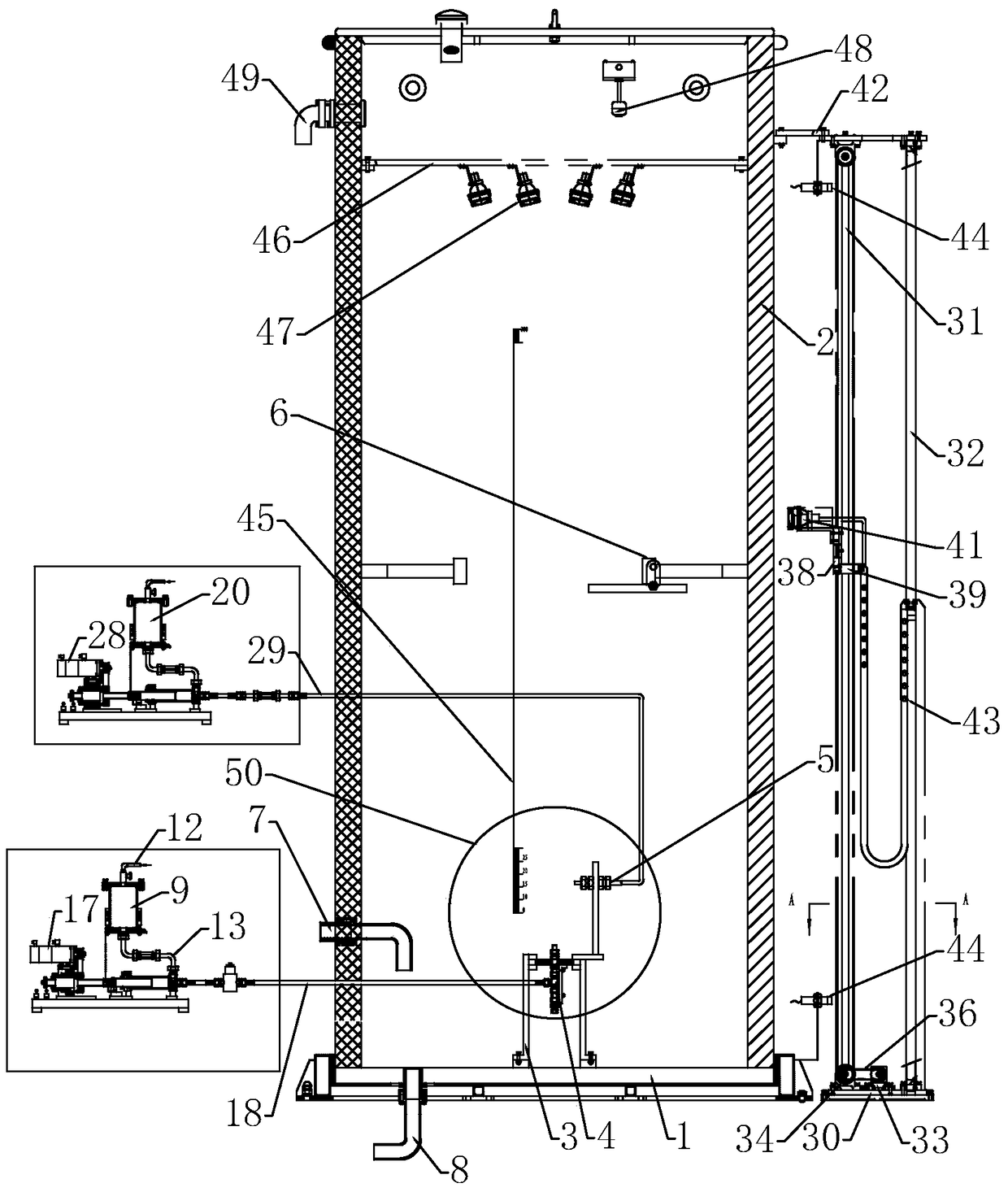

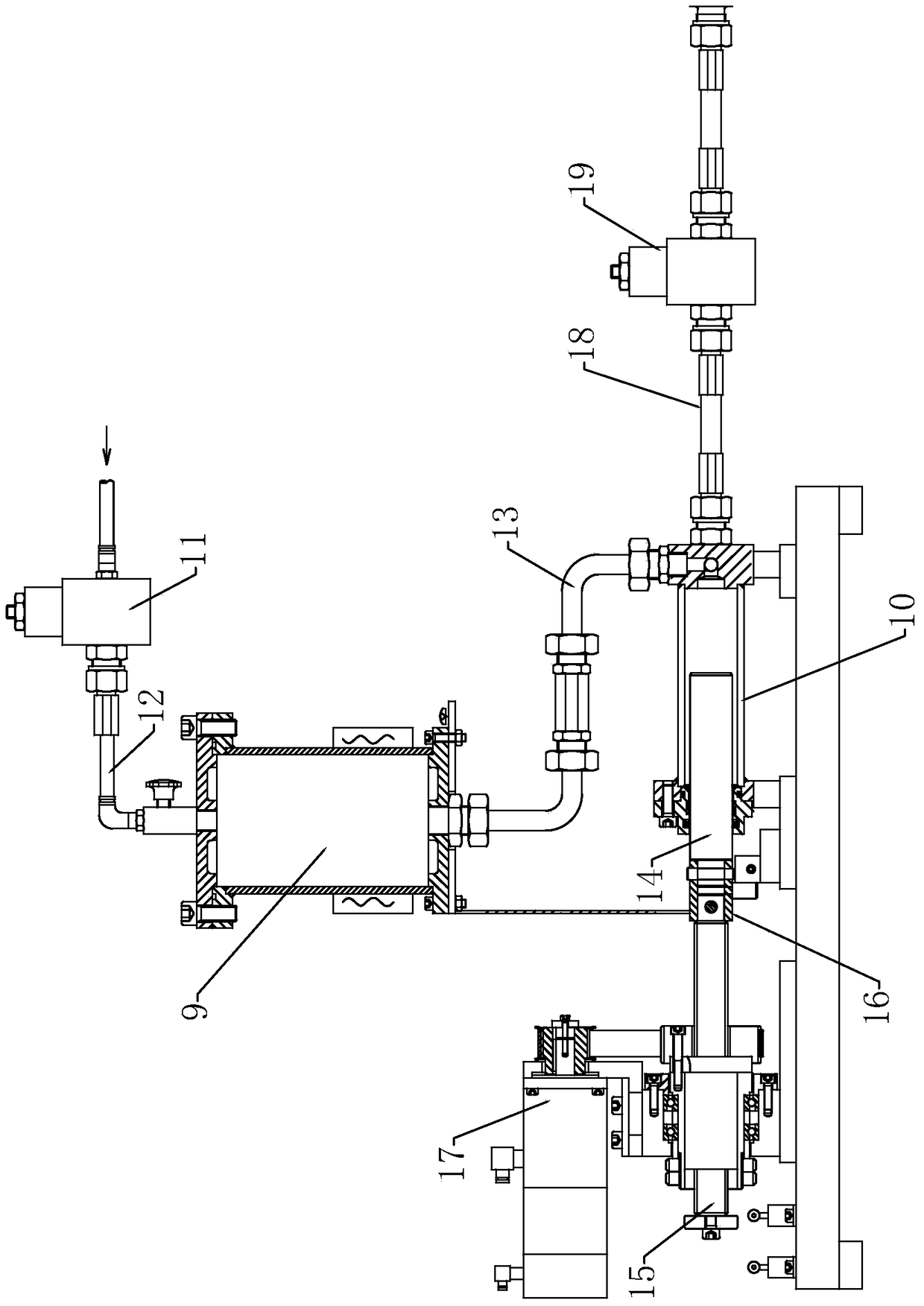

[0033] as attached figure 1 , 3 , 4, 5, 6 and 7, the vertical simulation device of this submarine oil spill comprises a main body tank 2 with a fixed chassis 1 at the bottom, a support frame 3 is provided at the bottom of the main body tank 2, and on the support frame 3 An injector 4 is provided, and a degreaser nozzle 5 is provided above the right side of the support frame 3, and a laser particle analyzer 6 is provided on the middle side wall of the main water tank 1 above the degreaser nozzle 5; An oil injection unit connected to the inlet of the injector 4 is provided on the left side, and a dispersant injection unit connected to the inlet of the dispersant nozzle 5 is provided on the left side outside the main water tank 2 above the oil injection unit, and on the right side outside the main water tank 2 A liftable high-speed camera system is provided on the side; the laser ionizer 6, the oil injection unit, the dispersant injection unit and the liftable high-speed camera ...

Embodiment 2

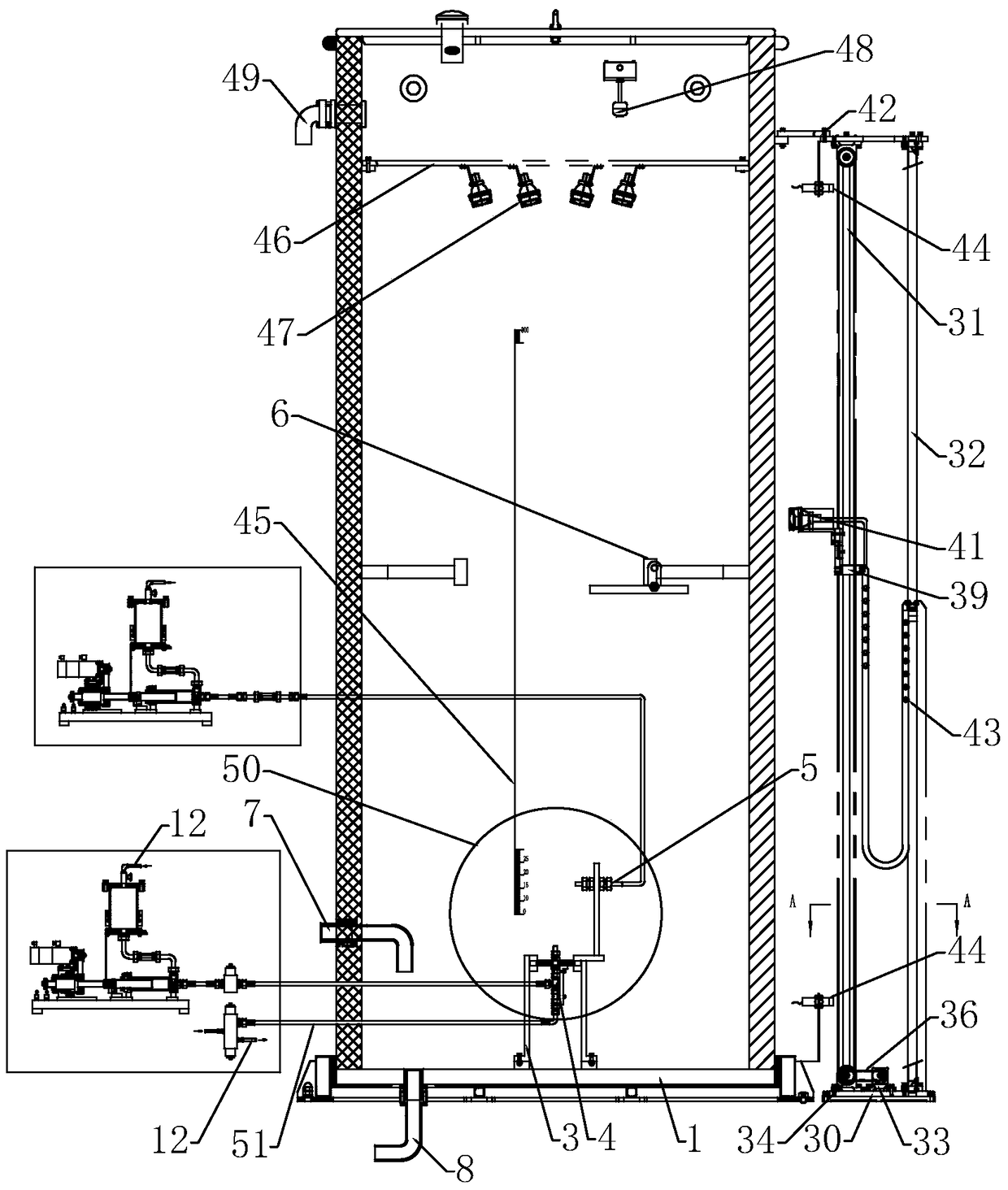

[0045] as attached Figure 2-6 As shown, the vertical simulation device of seabed oil spill as in Embodiment 1, the difference is that it also includes a gas injection unit, and the gas injection unit includes a third pipeline arranged below the first high pressure pipeline 18 51, the outlet of the third pipeline 51 is connected to the bottom inlet of the injector 4, and the inlet of the third pipeline 51 is connected to the gas source; a third electromagnetic valve 52 is provided on the third pipeline 51, so that The third solenoid valve 52 is controlled by a controller.

[0046] The working process of the vertical simulating device of this seabed oil spill is the same as that of the vertical simulating device of embodiment 1 seabed oil spilling, and the difference is that a first pipeline with the oil injection unit is connected at the injector 4 bottom 12 connected to the third pipeline 51, a third solenoid valve 52 controlled by the controller is provided on the third pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com