System and method for simultaneous determination of pressure dropping changes and combustion speeds during cigarette combustion

A technology of burning rate and cigarette, which is applied in the direction of chemical analysis using combustion, and achieves the effects of high work efficiency, easy operation and accurate test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

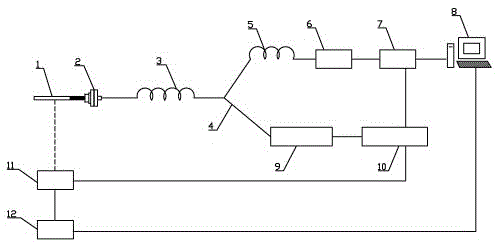

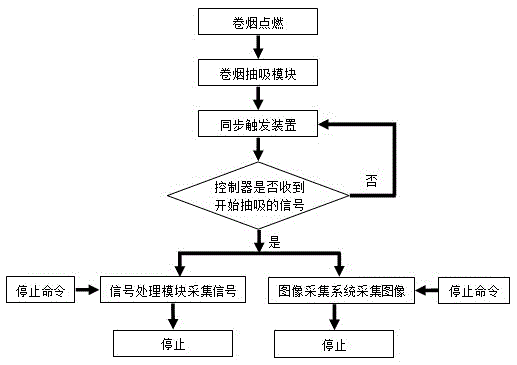

[0047] A device for simultaneously measuring the change in pressure drop and the burning rate of a cigarette when it is burned, such as figure 1 , including a cigarette holder 2, a three-way regulating valve 4, a pressure sensor 6, a signal processing module 7, a controller 8, a cigarette suction system 9, a synchronous trigger device 10 for capturing suction signals, an image acquisition system 11, Data processing system 12, the outlet of cigarette holder 2 is connected to port 1 of three-way regulating valve 4 through hose one 3; the input end of pressure sensor 6 is connected to port three of three-way regulating valve 4 through hose two 5 , the output end of the pressure sensor 6 is connected to the input end of the signal processing module 7; the input end of the cigarette suction system 9 is connected to port 2 of the three-way regulating valve 4, and the output end of the cigarette suction system 9 is connected to the synchronous trigger device 10 The input end of the s...

Embodiment 2

[0055] The structure of embodiment 2 is basically the same as that of embodiment 1. The difference between embodiment 2 and embodiment 1 is that the range of pressure sensor 6 is unchanged, its response frequency is 1KHz, the data acquisition frequency of signal processing module 7 is 50Hz, and the hose One 3. The sum of the volumes of the three-way regulating valve 4 and the hose two 5 is 10mL.

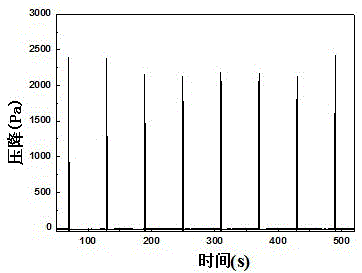

[0056] Take a certain brand of cigarette A, insert the cigarette into the holder of the smoking machine, and adjust the exposure of the camera. Input "A", test date, and test serial number in the "Information Entry" window of the cigarette burning speed measurement system, select a fixed length test, and set the burning length of the cigarette to 50 mm. Click "Start Test" on the measurement software and "Start Smoking" on the smoking machine software in sequence. The test ends when the cigarette burns to 50 mm. image 3 for the measurement result. In the "Data Query" window of the...

Embodiment 3

[0058] The structure of embodiment 3 is basically the same as that of embodiment 1. The difference between embodiment 3 and embodiment 1 is that the fixed length test is selected instead of the fixed port number test, the fixed number of suction ports is 9 ports, and the range of the pressure sensor 6 remains unchanged. , the response frequency is 1KHz, the data acquisition frequency of the signal processing module 7 is 100Hz, and the sum of the volumes of the first hose 3, the three-way regulating valve 4 and the second hose 5 is 100mL.

[0059] The system and method of this embodiment were used to measure the pressure drop and burning rate in the system when a certain brand of cigarette 1 was burning. Figure 4 is the measurement result in the third puff interval of the brand cigarette, Figure 5 It is the measurement result of the pressure drop of this brand of cigarettes within the time period of 15.42s to 15.67s. The results show that the cigarette is in a free burning st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com