Optical fiber for fiber bragg grating

An optical fiber, optical axis technology, applied in the direction of grating fiber, cladding fiber, optical waveguide light guide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the preferred embodiments for implementing the present invention will be described in detail with reference to the accompanying drawings. In the description of the drawings, the same symbols are used to denote the same elements, and repeated descriptions are omitted. The present invention is not limited to these embodiments, and the scope of the present invention is intended to be understood by the claims and their equivalents so as to include all modifications of these embodiments.

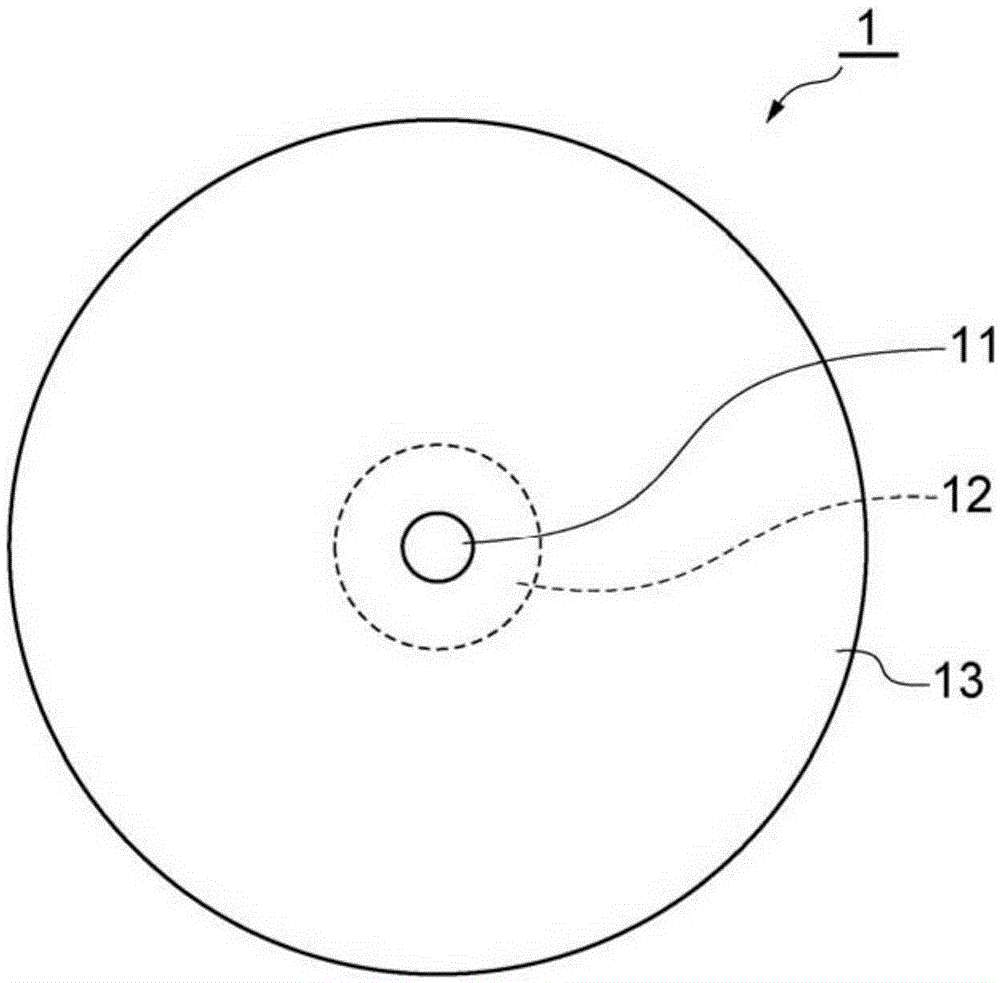

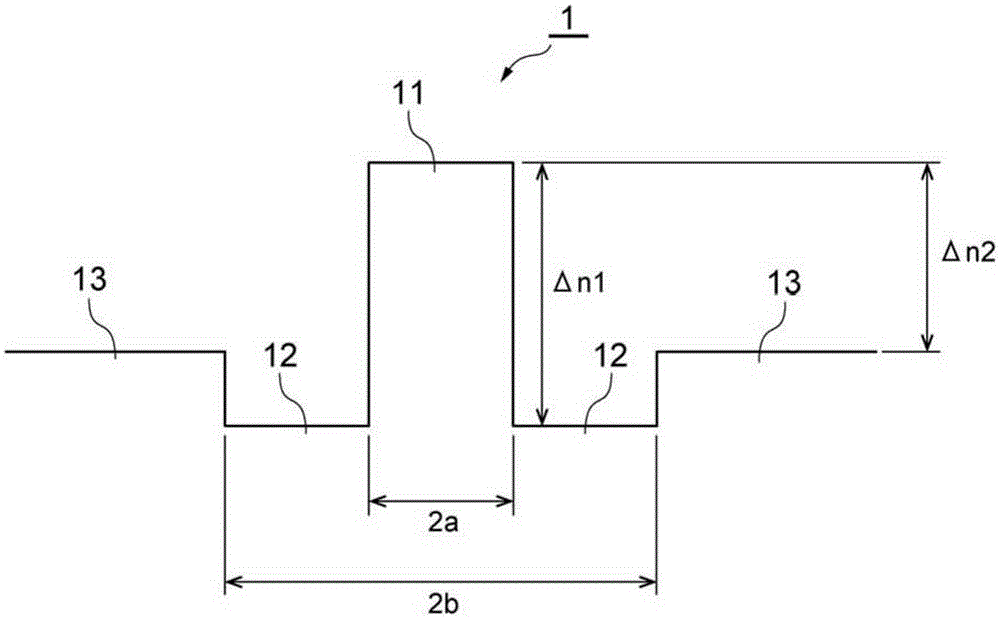

[0024] figure 1 It is a schematic diagram showing a cross section of the optical fiber 1 according to the embodiment of the present invention. The optical fiber 1 made of silicon-based glass includes: a core region 11, which includes the center of the optical axis; an optical cladding region 12, which is arranged around the core region 11; and a sheath region 13, which is arranged around the optical cladding region 12 . Core region 11 can contain Cl but not GeO 2 , It is not se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com