Internal Force Calculation and Design Method of Semi-integral Seamless Bridge Slab

A technology of seamless bridges and design methods, applied in computing, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

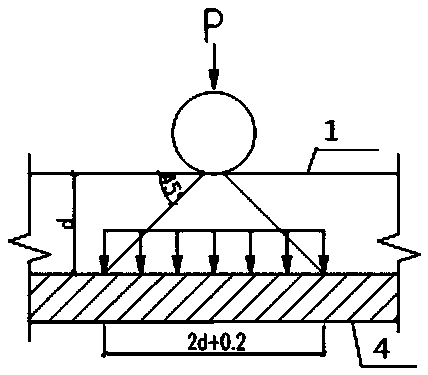

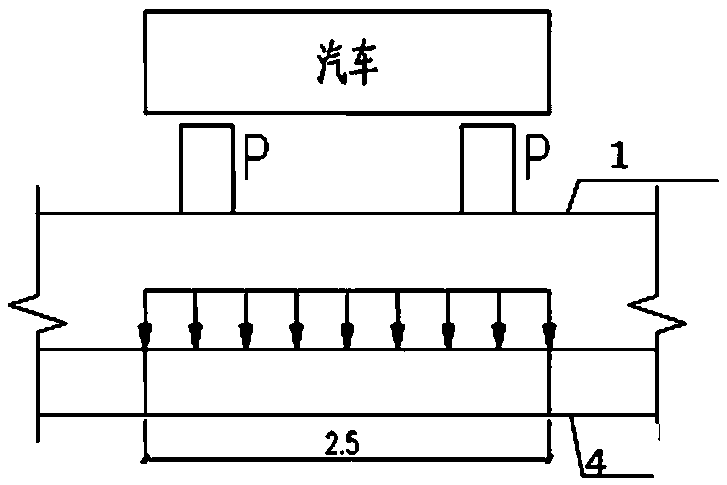

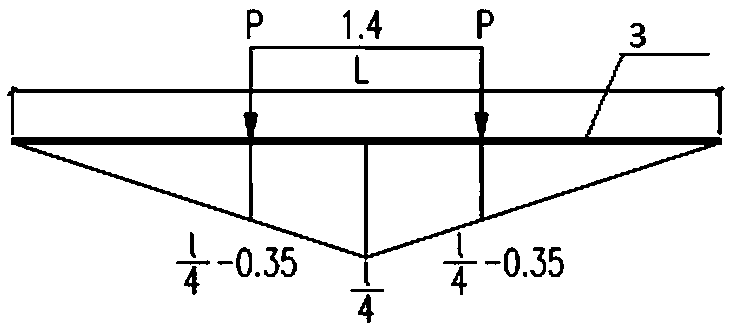

[0082] Example 1: In order to verify the feasibility of the above model calculation method, select four bridges with continuous semi-integral seamless beam bridges with hollow slabs whose lengths are 16×3m, 16×6m, 16×9m, and 16×12m respectively, corresponding to No. 1#, 2#, 3#, 4#, the main parameters are as follows: Among them, the main girder girder is 0.85m high, 1m wide, and the bridge width is 12m, that is, the cross bridge is spliced with 12 hollow slabs. The board is 8m long, 0.3m high and 12m wide. Both the main girder and the bridge head slab are made of C30 concrete material, and the steel bars are proposed to be HRB335 steel bars. The bridge adopts the continuous structure of the whole bridge, and the semi-integral abutment of the bridge head is seamlessly constructed. The support adopts one-way support and allows the bridge to move along the bridge direction, and is arranged symmetrically from the temperature center to ensure that the expansion and contraction d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap