Display panel and method for manufacturing same

A technology for display panels and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., capable of solving problems affecting the color saturation of display panels, complex circuit design, and different brightness attenuation ranges of luminescent materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

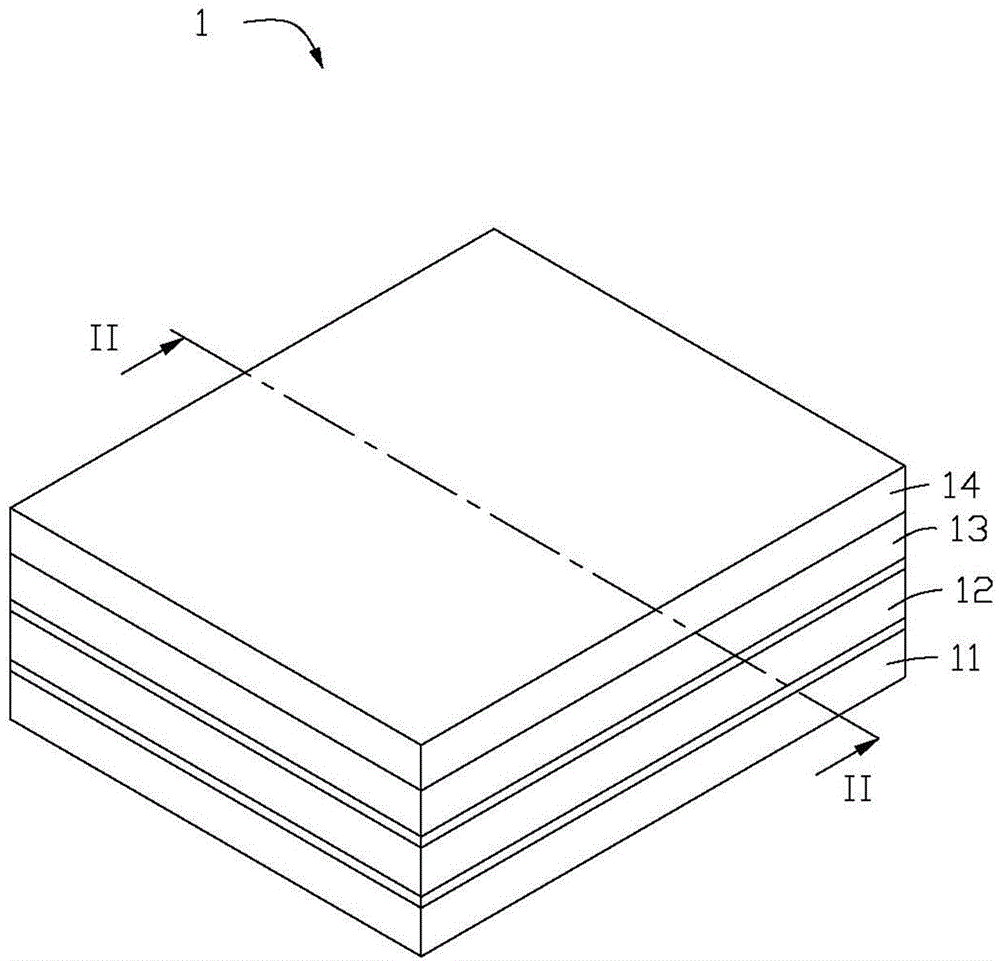

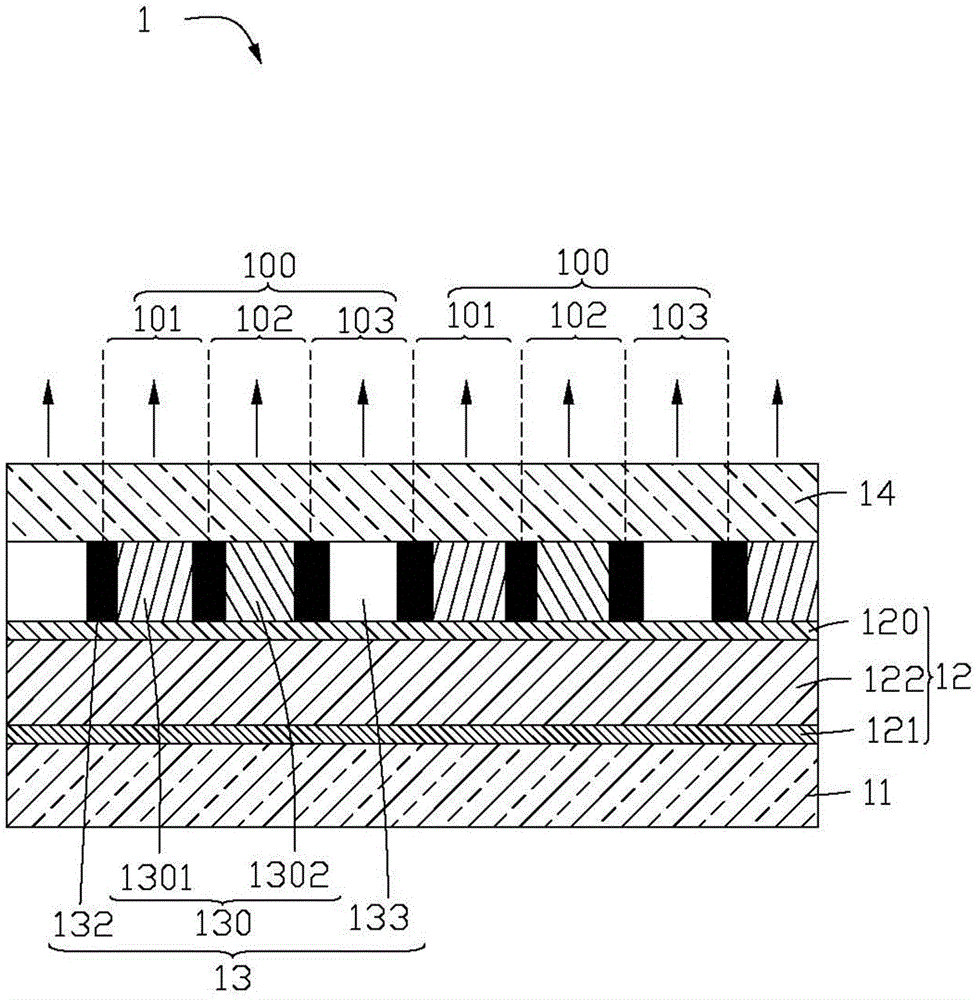

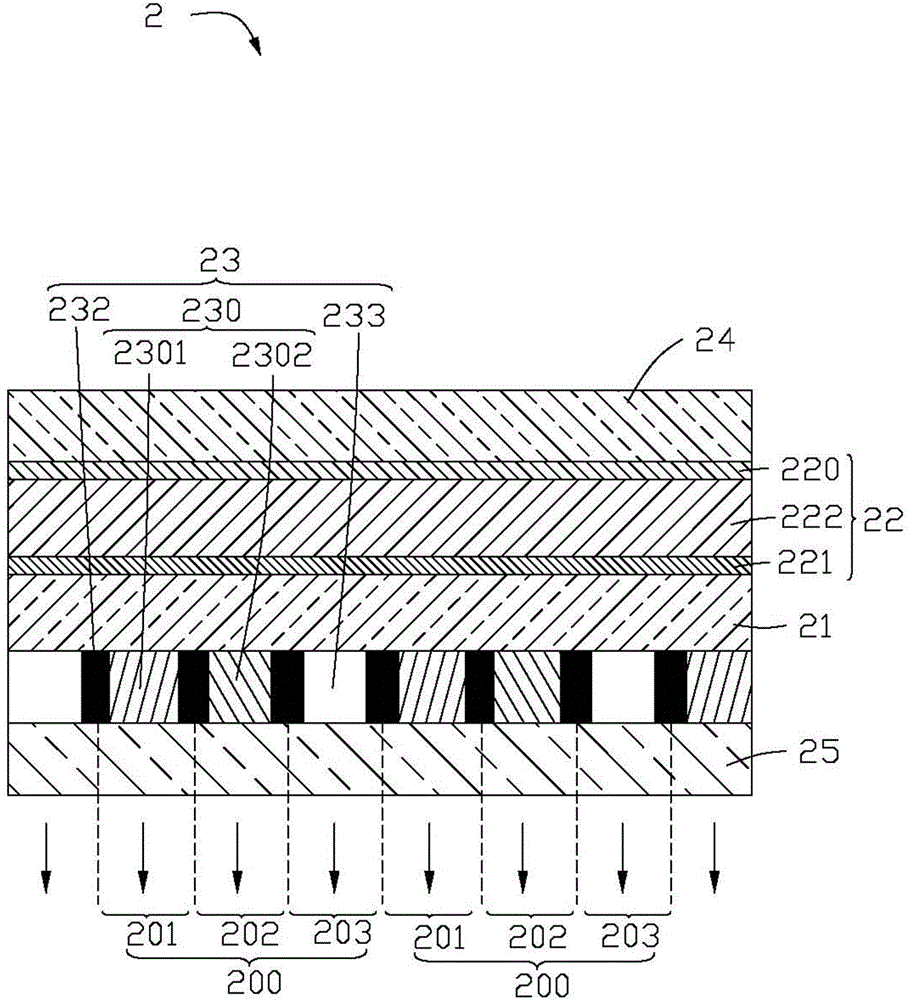

[0021] Such as figure 1 and figure 2 as shown, figure 1 is a schematic structural view of the display panel 1 provided in the first embodiment of the present invention, figure 2 yes figure 1 A cross-sectional view of panel 1 is shown in . In order to clearly illustrate the preferred embodiment of the present invention, the following figure 2 Only two pixels 100 of the display panel 1 are taken as an example for illustration. The display panel 1 includes a thin film transistor array 110 (see Figure 5 ) of the array substrate 11, the light emitting element 12 disposed on the array substrate 11, the color conversion layer 13 disposed on the light emitting side of the light emitting element 12, and the flat layer 14 covering the opposite side of the color conversion layer 13 and the light emitting element 12.

[0022] A plurality of pixels 100 are defined on the display panel 1 . Each pixel 100 includes at least a first sub-pixel 101 , a second sub-pixel 102 and a third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com