Optical film, preparation method thereof and display device

An optical diaphragm and diaphragm technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as the ability to limit the utilization rate of DBEF backlight, waste, etc., and achieve the effect of improving the utilization rate of backlight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

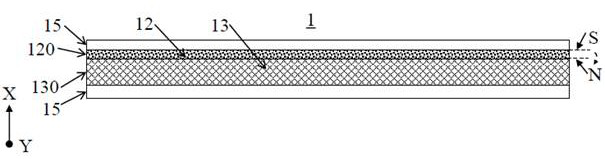

[0031] figure 1 A schematic structural diagram of the optical film provided by the first embodiment of the present application is shown.

[0032] like figure 1 As shown, the first embodiment of the present application provides an optical film 1, which includes a light-transmitting base material 11, magnetic powder 12 and a magneto-optical medium 13 disposed in the light-transmitting base material 11, and the magnetic powder 12 is used to form a surface magnetic field, The magneto-optical medium 13 is located in a surface magnetic field, so that the polarization direction of the linearly polarized light is rotated after passing through the magneto-optical medium 13 .

[0033] like figure 1 As shown, the surface magnetic field formed by the magnetic powder 12 of the optical film 1 has N pole and S pole oppositely arranged along the first direction X, and a magnetic field direction parallel to the first direction X can be generated between the N pole and the S pole. When the N...

no. 2 example

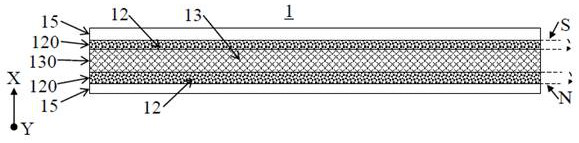

[0057] image 3 A schematic structural diagram of the optical film provided by the second embodiment of the present application is shown.

[0058] like image 3 As shown, the second embodiment of the present application also provides an optical film 1, which is similar in structure to the optical film 1 of the first embodiment, except that the magneto-optical medium layer 130 is sandwiched between two layers of between the magnetic layers 120 .

[0059] Specifically, the magnetic powder 12 and the light-transmitting substrate 11 are combined to form a layered magnetic layer 120 , the magneto-optical medium 13 and the light-transmitting substrate 11 are combined to form a magneto-optical medium layer 130 , and the magneto-optical medium layer 130 is sandwiched between two between the layered magnetic layers 120 . The magnetic powder of each layered magnetic layer 120 is magnetized in a magnetic field before being made into a layered structure, and the directions of the magne...

no. 3 example

[0068] Figure 4 A schematic structural diagram of the optical film provided by the third embodiment of the present application is shown.

[0069] like Figure 4 As shown, the third embodiment of the present application also provides an optical film 1 , which is similar in structure to the optical film 1 of the first embodiment, except that the light-transmitting substrate 11 , the magnetic powder 12 and the magneto-optical medium 13 is compounded to form a layered diaphragm, the magneto-optical medium 13 is a thin sheet structure, and the plane where the thin sheet structure is located is perpendicular to the magnetic field direction of the surface magnetic field.

[0070] Specifically, a mixed powder is composed of silica aerogel, ultra-fine NdFeB magnetic powder, and magneto-optical medium powder (such as YIG, Ga-doped YIG, or CdMgTe crystal), and the mixed powder is placed in a magnetic field by vibration. The magnetic powder 12 is magnetized. After heating and curing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com