Miniature coreless generator

An ironless, generator technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of coil winding copper loss, reduce motor efficiency, increase driving power, etc., to increase product service life and improve product quality. Work efficiency, the effect of increasing the torque to volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

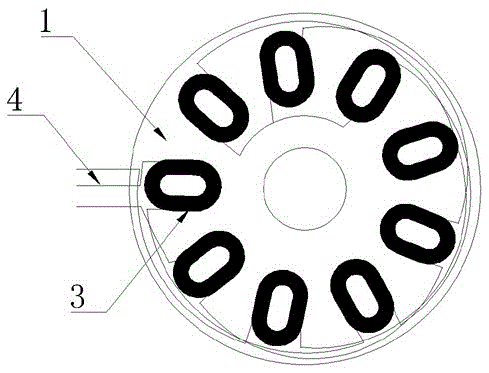

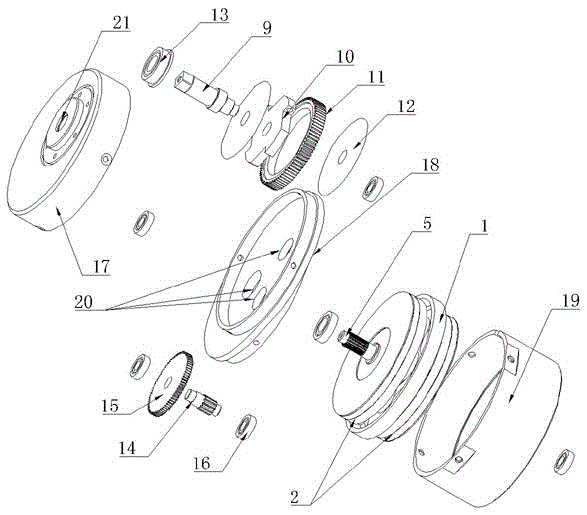

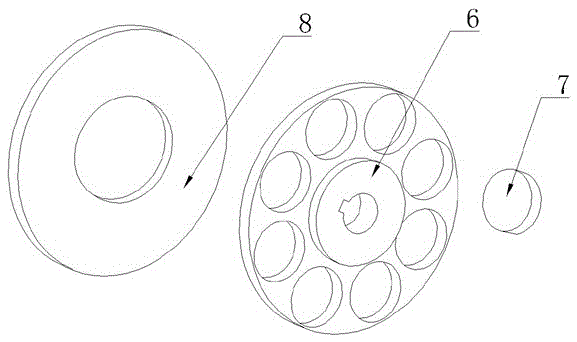

[0015] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a casing and a transmission part arranged in the casing, and a power generation part connected with the transmission part is also arranged in the casing, and the power generation part includes a coil skeleton (1) and the magnet rotor (2) attached to the left and right ends of the coil bobbin (1), the coil bobbin (1) is fixedly arranged on the casing, and evenly distributed on any side of the coil bobbin (1) There are several coils (3), and every two adjacent coils (3) are electrically connected, and three output lines electrically connected to the coils (3) are also arranged on the coil frame (1) (4), a motor shaft (5) connected to the transmission part is further arranged on the coil frame (1), and the magnet rotor (2) is fixedly connected to the motor shaft (5). In the present invention, the magnet rotor (2) includes an iron positioning ring (6), magnets (7) evenly distributed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com