Roll cutting method and associated equipment

A hobbing and equipment technology, which is used in the field of rotation driven by the rotation axis of the piece, can solve the problems of reducing the processing quality, shortening the tool life, vibration, etc., and achieves the effect of increasing the number of processes and increasing the cutting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

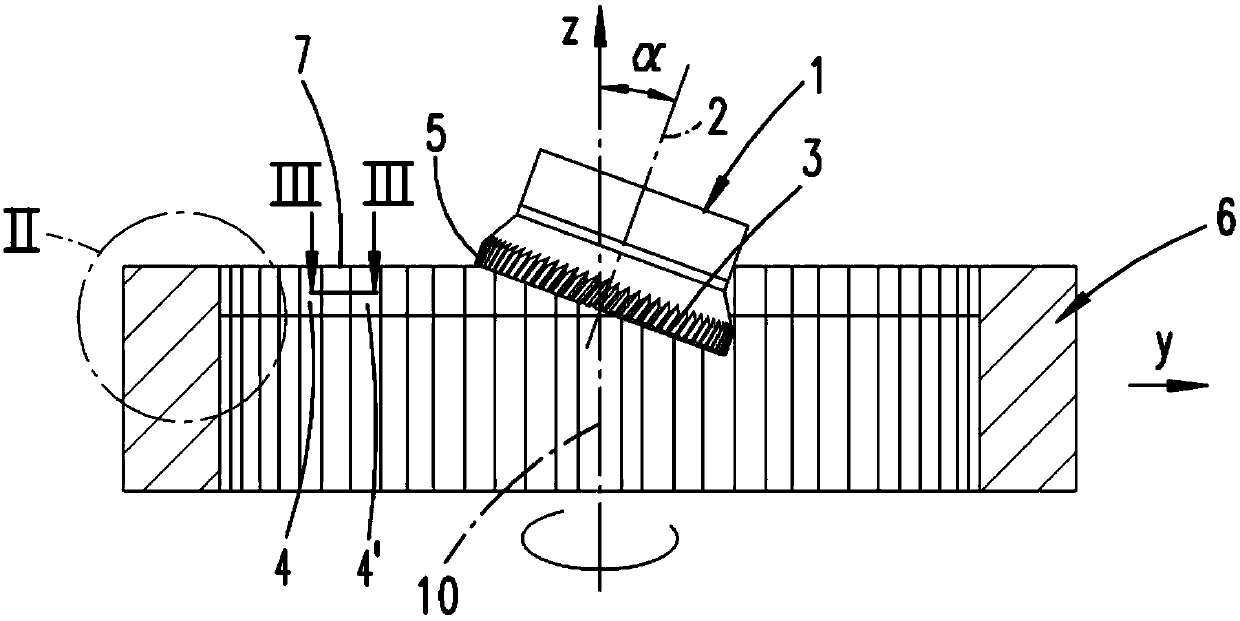

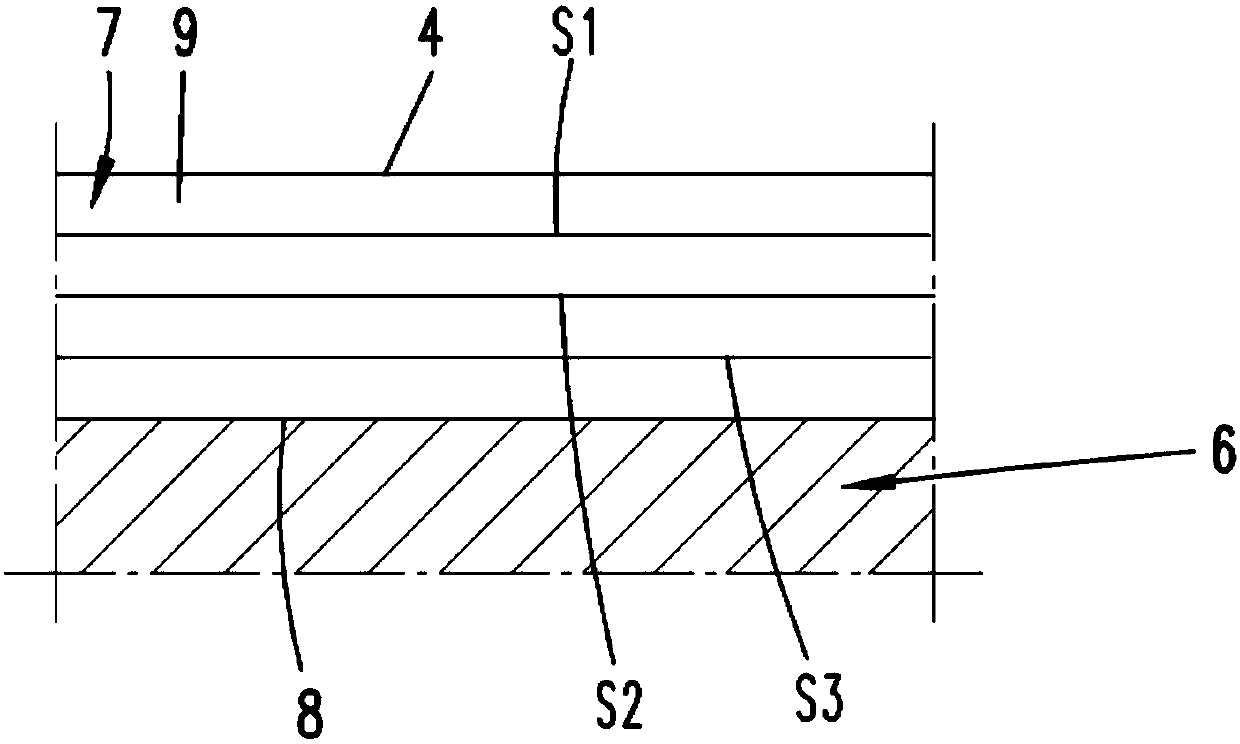

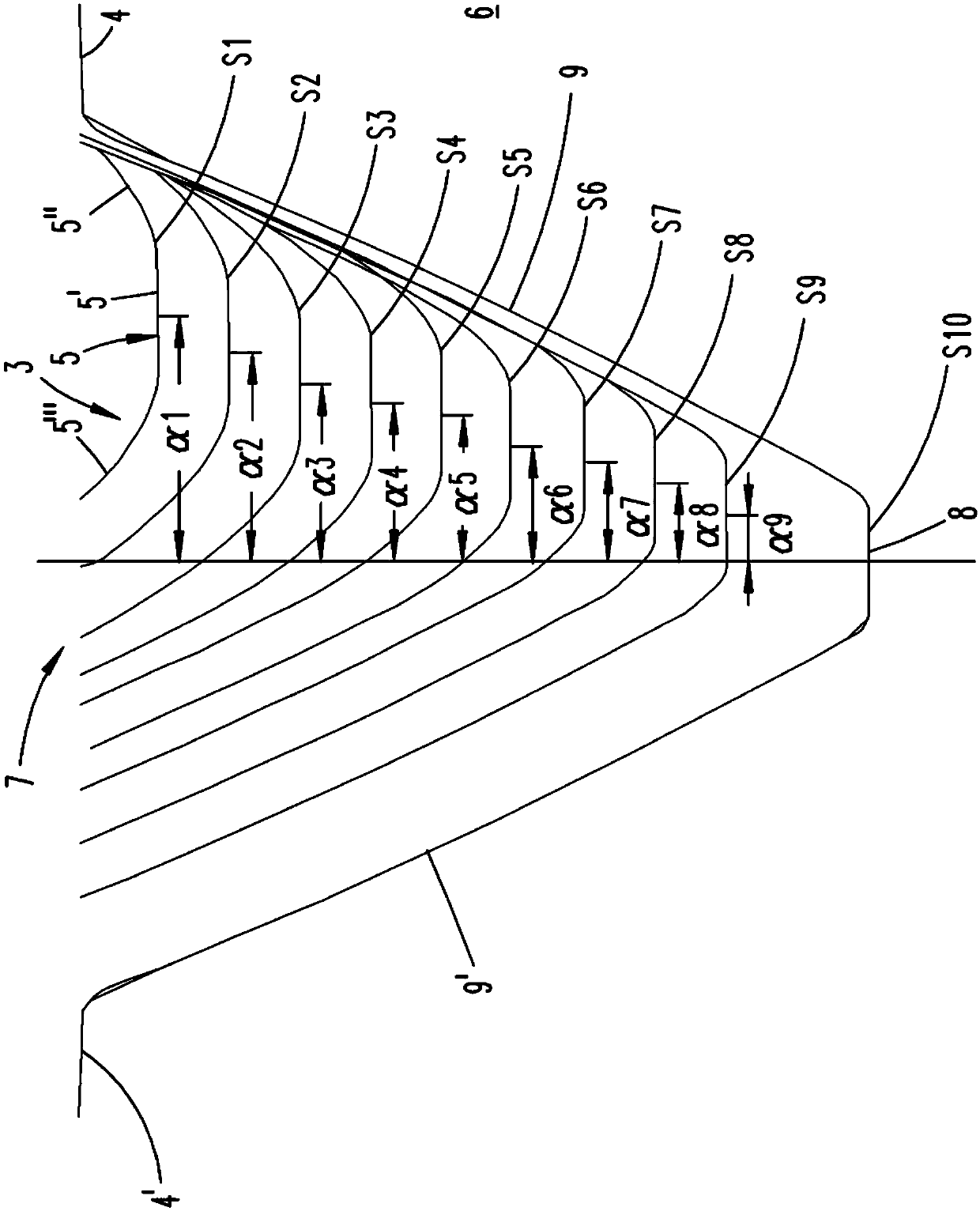

[0025] With the equipment described below, the internal teeth or external teeth are cut in the blank by the hobbing method. This is done by cutting the gear 1 either on the inner or outer surface of the smooth wall of the blank, or in the tooth flanks of the blank with prefabricated teeth. This method consists of a number of successive roughing processes, in which the roughing is performed once. After many rough machining processes, at least one finishing process can be connected, and then a finishing process is performed. The difference between finishing and rough cutting is mainly to reduce the transverse feed, that is, a smaller cutting amount, but still through a changed feed rate.

[0026] in Image 6 The equipment shown in has a frame not shown in the figure, which carries a tool spindle 11 with a chuck, and a cutting gear 1 with cutting teeth 3 is fixed in the chuck. The tool spindle 11 can be driven to rotate by an electric drive 12. The driver 12 is controlled by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com