A kind of processing method of high-quality blueberry concentrated juice with high anthocyanin content

A technology with high anthocyanins and processing methods, applied in the field of food processing, can solve the problems of reducing heating intensity and time, achieve the effect of improving nutritional and health care value, eliminating bitterness and astringency, and weakening the loss of natural aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

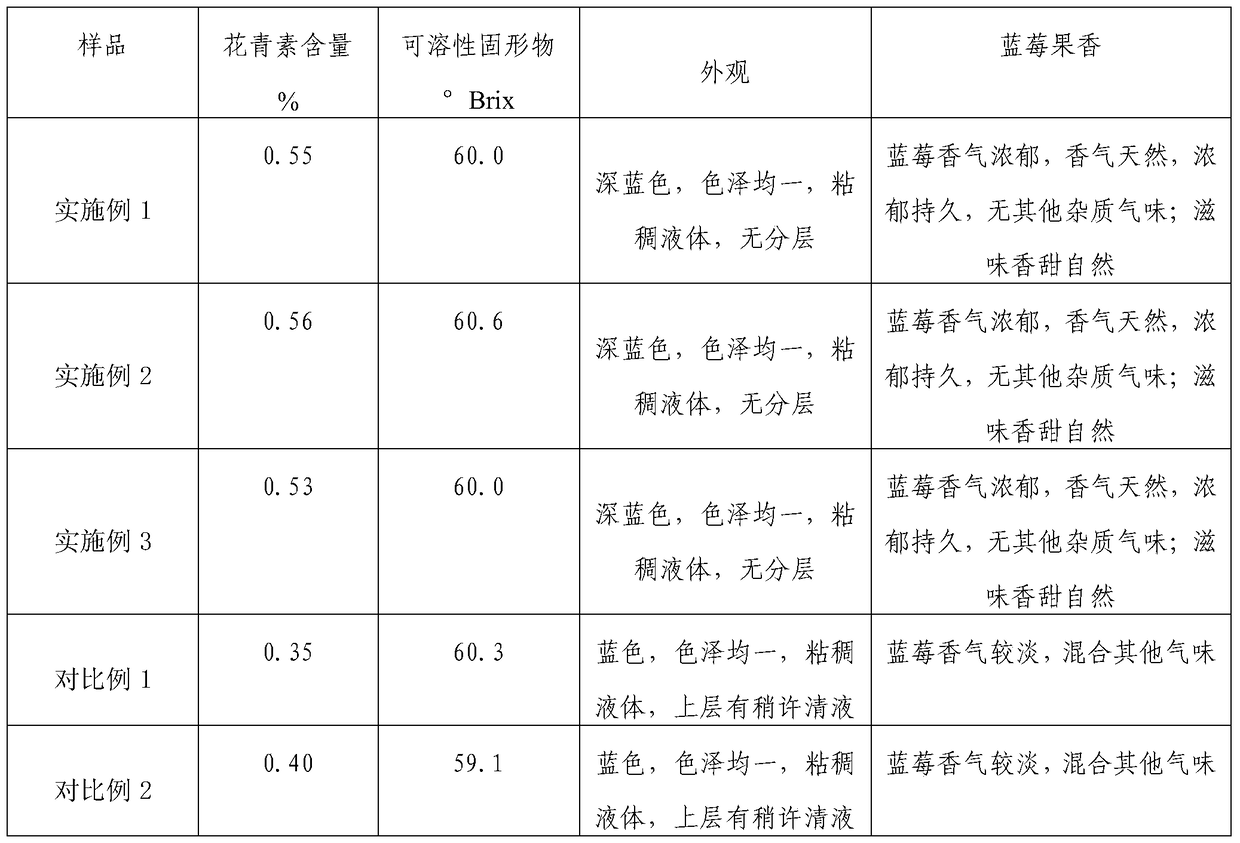

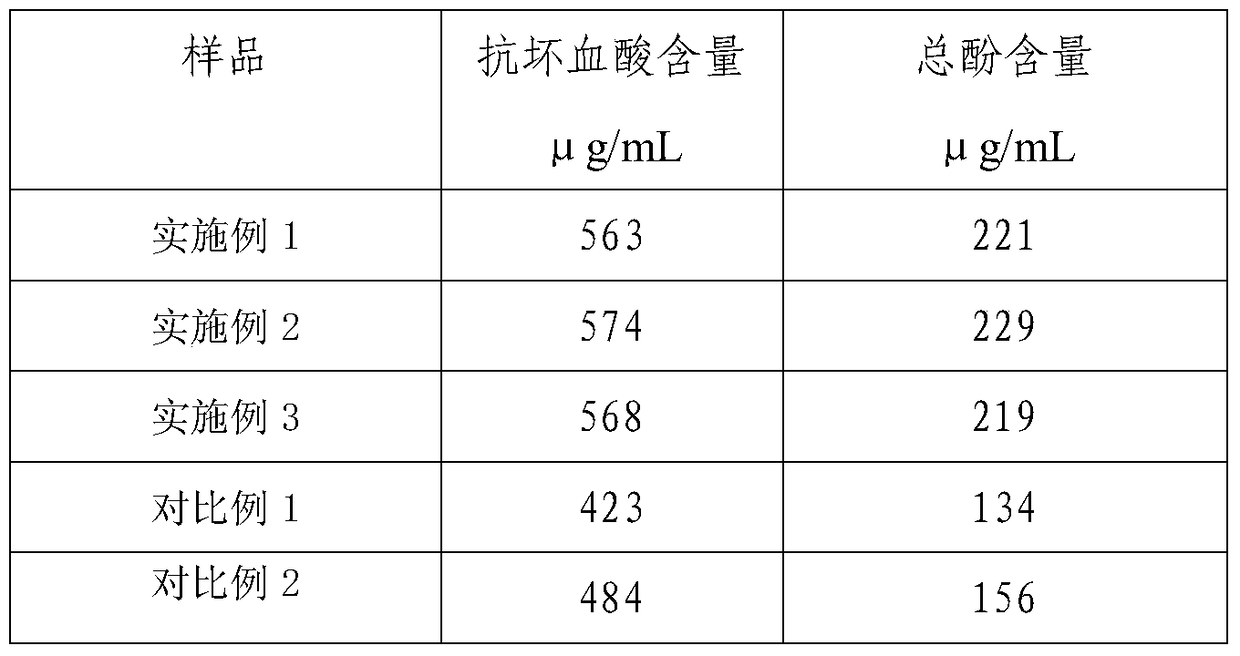

Examples

Embodiment 1

[0035] A processing method of high-quality blueberry concentrated juice with high anthocyanin content, the steps are as follows:

[0036] (1) Material preparation: screen 100kg of fresh blueberry fruit, wash and drain;

[0037] (2) Crushing: the clean blueberry fresh fruit of step (1) is crushed by a hammer crusher, and the screen aperture of the hammer crusher is 3 mm to obtain blueberry puree;

[0038] (3) Juicing and separation: the blueberry puree obtained in step (2) is separated from the juice slag by using a belt-type juice extractor with an aperture of 0.5 mm to obtain blueberry turbid juice;

[0039] (4) ceramic membrane ultrafiltration: the blueberry cloudy juice that step (3) makes is pumped into the ceramic membrane ultrafiltration equipment that aperture is 0.04 μ m and carries out ultrafiltration, and working pressure is 0.2MPa, obtains blueberry clear juice after ultrafiltration;

[0040](5) pump the blueberry clear juice obtained after the ultrafiltration of s...

Embodiment 2

[0045] A processing method of high-quality blueberry concentrated juice with high anthocyanin content, the steps are as follows:

[0046] (1) Material preparation: screen 130kg of fresh blueberry fruit, wash and drain;

[0047] (2) Crushing: the clean blueberry fresh fruit of step (1) is crushed by a hammer crusher, and the screen aperture of the hammer crusher is 4mm to obtain blueberry puree;

[0048] (3) Juicing and separation: the blueberry puree obtained in step (2) is separated by a belt-type juice extractor with an aperture of 0.4mm to obtain blueberry turbid juice;

[0049] (4) ceramic membrane ultrafiltration: the blueberry cloudy juice that step (3) makes is pumped into the ceramic membrane ultrafiltration equipment that aperture is 0.05 μ m to carry out ultrafiltration, and working pressure is 0.2MPa, obtains blueberry clear juice after ultrafiltration;

[0050] (5) pump the blueberry clear juice obtained after the ultrafiltration of step (4) into a reverse osmosis...

Embodiment 3

[0055] The processing method of step-by-step production of fresh wolfberry concentrated pulp as described in embodiment 1, the difference is:

[0056] In step (5), the clear blueberry juice is pre-concentrated to a Brix of 21.2°; the mass ratio of the distillate obtained by molecular distillation in step (6) to the raffinate is 1:2.1, and the raffinate is concentrated by blueberry molecular distillation Juice, Brix 31.3°;

[0057] Low-temperature concentration of the blueberry molecularly distilled concentrated juice prepared in step (6) to a Brix of 70.8°;

[0058] The blueberry concentrated juice obtained in step (7) and the distillate obtained in step (5) are mixed according to the mass ratio of 5.6:1, and stirred evenly to obtain high-quality blueberry concentrated juice with a Brix of 60° .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com