Method for preparing protein hydrolyzate from abalone viscera through complex enzyme hydrolysis

A protein hydrolyzate and compound enzymatic hydrolysis technology are applied in the field of compound enzymatic hydrolysis of abalone viscera to prepare protein hydrolyzate, which can solve problems such as low protein hydrolysis yield, and achieve the effects of high hydrolysis rate, complete hydrolysis, and easy control of process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

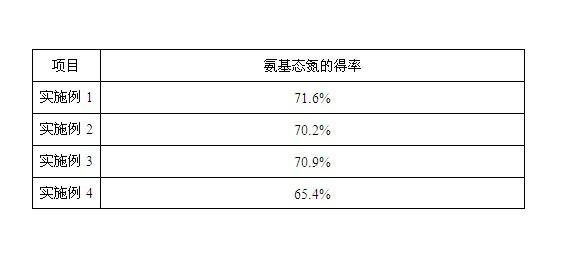

Examples

Embodiment 1

[0015] 1. After the abalone viscera is taken out and cleaned, it is roughly crushed with a beater, and then put into a colloid mill for micronization treatment for 10 minutes. The speed of the colloid mill is 3000 rpm to obtain abalone viscera slurry;

[0016] 2. Take a certain amount of abalone viscera slurry, add water and stir well, and adjust the solid-liquid ratio to 1:1;

[0017] 3. Add sodium hydroxide solution with a mass concentration of 1mol / L to adjust the pH of the mixture to 8;

[0018] 4. Add the compound enzyme uniformly mixed with alkaline protease and papain, heat for enzymatic hydrolysis treatment, stir once every 10-15 minutes to obtain enzymatic hydrolyzate, wherein the weight ratio of alkaline protease and papain is 2 : 1, the addition amount of compound enzyme is 0.5%, the enzymatic hydrolysis treatment temperature is 45 ℃, and the time is 5h;

[0019] 5. Put the hydrolyzate in a jacketed pot, heat to 85°C, inactivate the enzyme for 10 minutes, inactivat...

Embodiment 2

[0023] 1. After the abalone viscera is taken out and cleaned, it is roughly crushed with a beater, and then put into a colloid mill for micronization treatment for 10 minutes. The speed of the colloid mill is 3000 rpm to obtain abalone viscera slurry;

[0024] 2. Take a certain amount of abalone viscera slurry, add water and stir well, and adjust the solid-liquid ratio to 3:2;

[0025] 3. Add sodium hydroxide solution with a mass concentration of 1mol / L to adjust the pH of the mixture to 7.5;

[0026] 4. Add the compound enzyme uniformly mixed with alkaline protease and papain, heat for enzymatic hydrolysis treatment, and stir once every 10-15 minutes to obtain an enzyme hydrolyzate, wherein the weight ratio of alkaline protease and papain is 1 : 1, the addition amount of compound enzyme is 0.6%, the enzymatic hydrolysis treatment temperature is 50℃, and the time is 4.5h;

[0027] 5. Put the hydrolyzate in a jacketed pot, heat to 85°C, inactivate the enzyme for 10 minutes, in...

Embodiment 3

[0031] 1. After the abalone viscera is taken out and cleaned, it is roughly crushed with a beater, and then put into a colloid mill for micronization treatment for 10 minutes. The speed of the colloid mill is 3000 rpm to obtain abalone viscera slurry;

[0032] 2. Take a certain amount of abalone viscera slurry, add water and stir well, and adjust the solid-liquid ratio to 3:1;

[0033] 3. Add sodium hydroxide solution with a mass concentration of 1mol / L to adjust the pH of the mixture to 7.5;

[0034] 4. Add the compound enzyme uniformly mixed with alkaline protease and papain, heat for enzymatic hydrolysis treatment, stir once every 10-15 minutes to obtain enzymatic hydrolyzate, wherein the weight ratio of alkaline protease and papain is 2 : 1, the addition amount of compound enzyme is 0.7%, the enzymatic hydrolysis treatment temperature is 50 ℃, and the time is 5h;

[0035] 5. Put the hydrolyzate in a jacketed pot, heat to 85°C, inactivate the enzyme for 10 minutes, inactiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com