Vertical type stirred-free polymerization reactor

A polymerization reactor, non-stirring technology, applied in chemical methods, chemical instruments and methods, chemical/physical processes, etc. to make liquids react with liquids, which can solve the problems of slow reaction speed, low production efficiency, small heating area, etc. , to achieve the effect of stable product quality, low power consumption and failure rate, and uniform falling film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

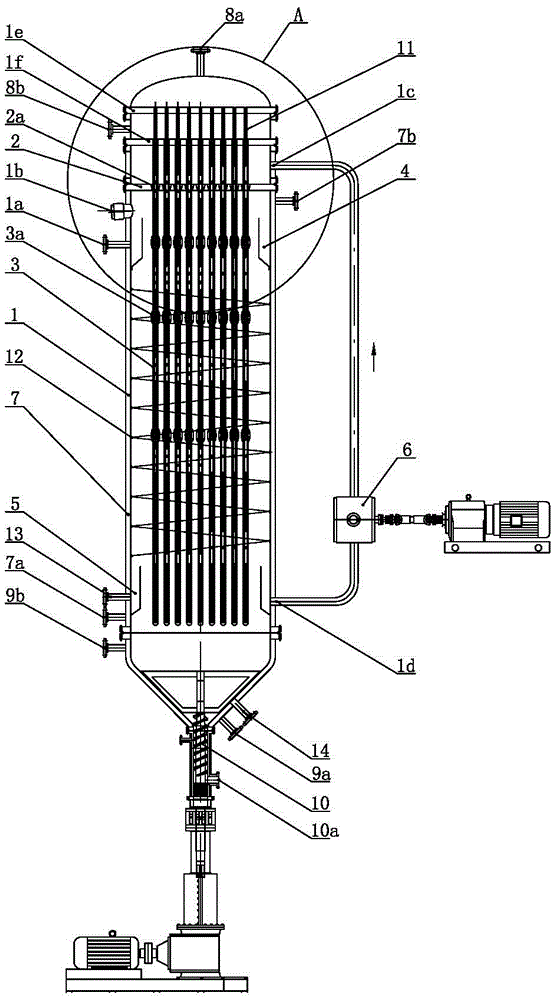

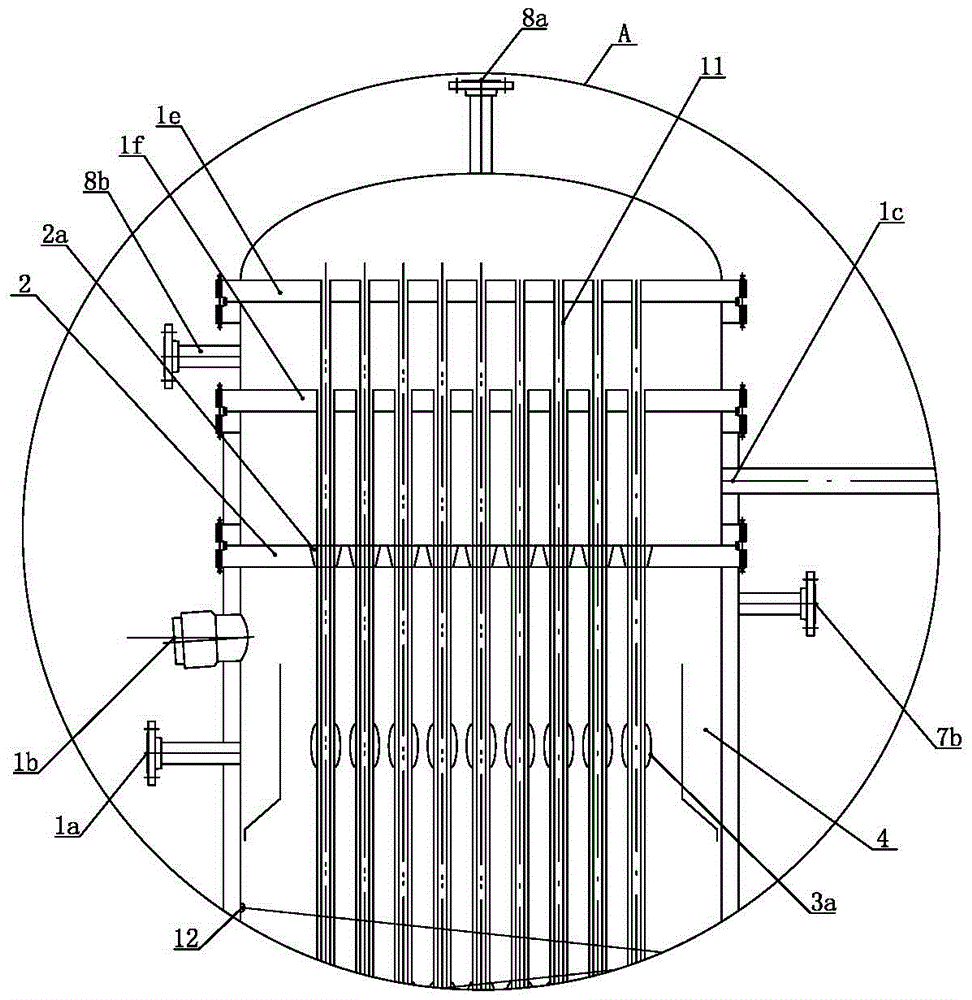

[0021] Such as figure 1 and figure 2 As shown, the vertical non-stirring polymerization reactor of the present invention comprises a cylinder 1 which is vertically arranged and closed at both ends, and the upper part of the cylinder cavity is provided with a horizontal liquid distribution plate 2 which partitions the cylinder laterally. 2 is provided with a liquid distribution hole 2a, and a falling film tube 3 is provided in the liquid distribution hole 2a, and the two are coaxial. The liquid distribution hole 2a is funnel-shaped with a large top and a small bottom, which is convenient for sufficient material to flow into the liquid distribution hole 2a. The gap between the small end of the liquid distribution hole 2a and the falling film tube 3 controls the thickness of the falling film. The falling film tube 3 extends vertically downward, and the inner cavity of the falling film tube 3 is inserted with a heat medium heating tube 11. The upper outer wall of the cylinder bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com