Preparation method of Pd/TiO2 nanowire catalyst, prepared catalyst and application thereof

A nanowire and catalyst technology is applied in the preparation of Pd/TiO2 nanowire catalyst, the obtained catalyst and its application field, which can solve the problems such as no relevant research reports, and achieve the effects of high activity, simple operation, and easy recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

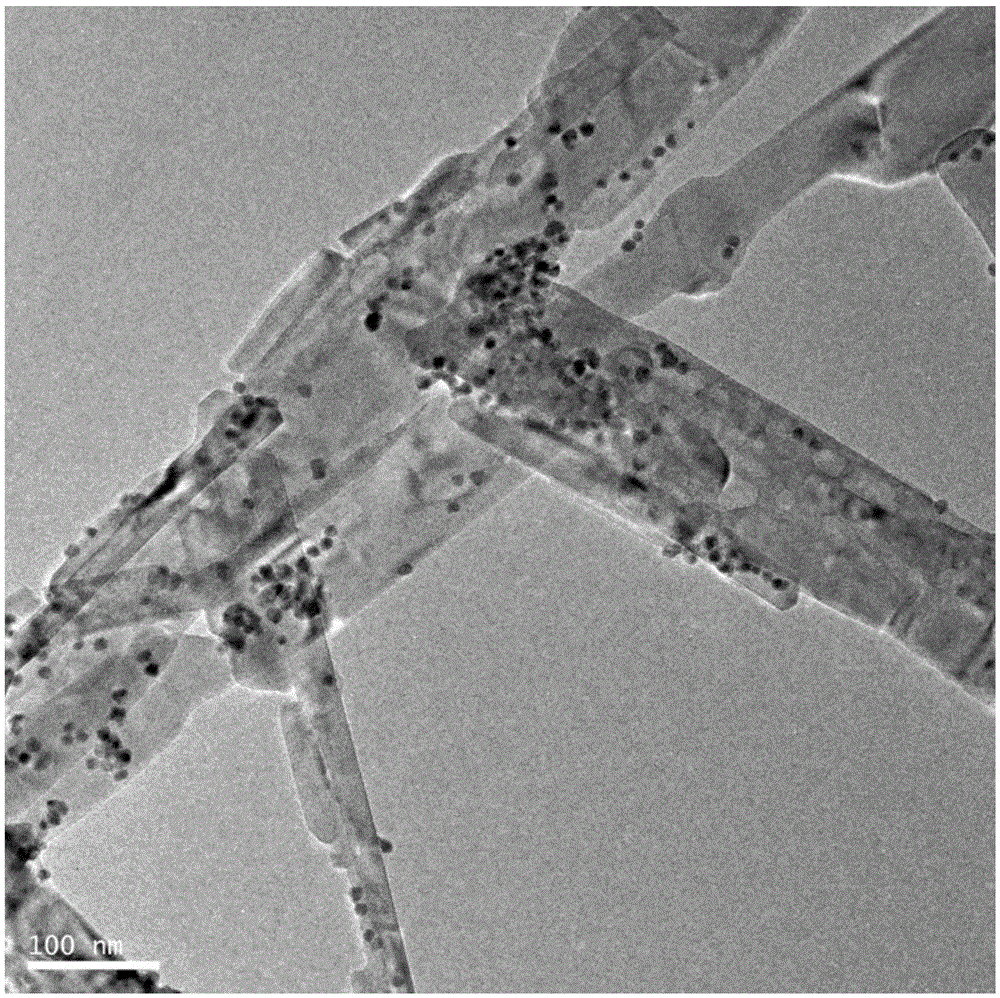

[0023] 1.5g of TiO 2 Add (P25) powder into NaOH aqueous solution, stir thoroughly for 30min, and transfer the solution to a 200mL hydrothermal reaction kettle, react hydrothermally at 200°C for 48h, wash with hydrochloric acid, wash with water, dry, and roast at 450°C 4h, to obtain one-dimensional TiO 2 Nanowire support, named TiO 2 (450).

[0024] Dry and pulverize the leaves of Cinnamomum camphora plant, take 2g and add 200mL water, stir for 2h and then filter to obtain filtrate A, take 30mL of filtrate and add 200 microliters of 74mM palladium nitrate aqueous solution, and stir at 90°C for 1.0h to obtain Solution B, the appropriate amount of TiO 2 (450) The nanowire carrier is added to the solution B, so that the loading amount of Pd is 1wt%, and after stirring for 1 h, it is filtered, washed with water, and dried in vacuum to obtain powdered Pd / TiO 2 Nanowire Catalyst A.

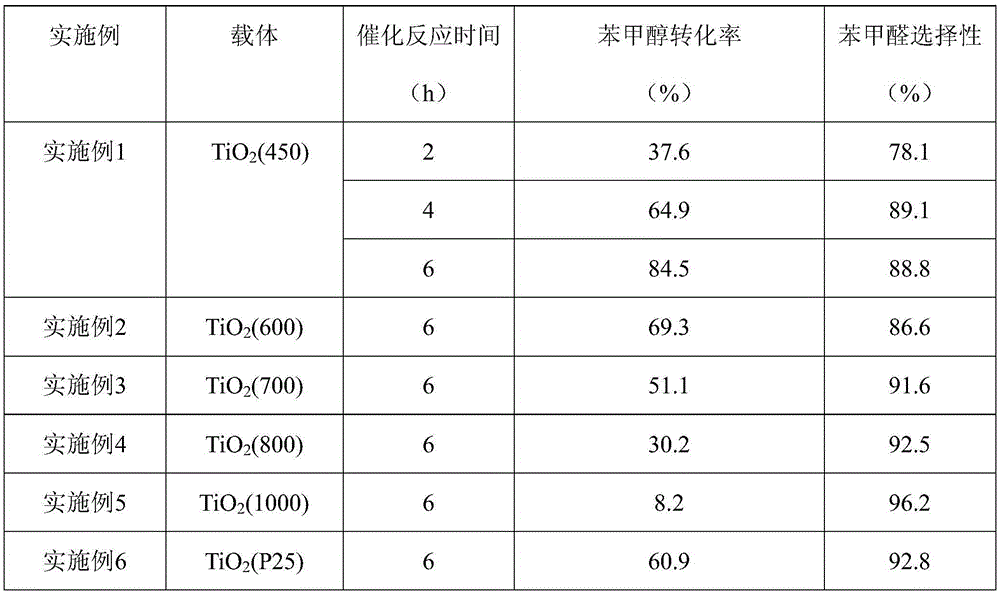

[0025] Oxidation reaction of benzyl alcohol: Pd / TiO was added to a 50mL three-necked flask 2 Ad...

Embodiment 2

[0027] 1.5g of TiO 2 (P25) powder was added to NaOH aqueous solution, stirred thoroughly for 30min, and the solution was transferred to a 200mL hydrothermal reaction kettle, hydrothermally reacted at 200°C for 48h, washed with hydrochloric acid, washed with water, dried, and roasted at 600°C 4h, to obtain one-dimensional TiO 2 Nanowire support, named TiO 2 (600).

[0028] Solution B is prepared according to the method of Example 1, and an appropriate amount of TiO 2 The nanowire carrier was added to solution B, so that the loading amount of Pd was 1wt%, and after stirring for 1 h, it was filtered, washed with water, and dried in vacuum to obtain powdered Pd / TiO 2 Nanowire Catalyst B. Catalyst evaluation conditions are the same as in Example 1, and the catalytic reaction results are shown in Table 1.

Embodiment 3

[0030] 1.5g of TiO 2 (P25) powder was added to NaOH aqueous solution, stirred thoroughly for 30min, and the solution was transferred to a 200mL hydrothermal reaction kettle, hydrothermally reacted at 200°C for 48h, washed with hydrochloric acid, washed with water, dried, and roasted at 700°C 4h, to obtain one-dimensional TiO 2 Nanowire support, named TiO 2 (700).

[0031] Solution B is prepared according to the method of Example 1, and an appropriate amount of TiO 2 The nanowire carrier was added to solution B, so that the loading amount of Pd was 1wt%, and after stirring for 1 h, it was filtered, washed with water, and dried in vacuum to obtain powdered Pd / TiO 2 Nanowire Catalyst C. Catalyst evaluation conditions are the same as in Example 1, and the catalytic reaction results are shown in Table 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap