A floating grinding method and tooling

A technology of tooling and grinding rods, which is applied in the field of mechanical processing, can solve the problems of poor surface roughness of the grinding inner hole, easily hurt the operator, waste products, etc., achieve stable and uniform grinding process, improve grinding quality, and smooth flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

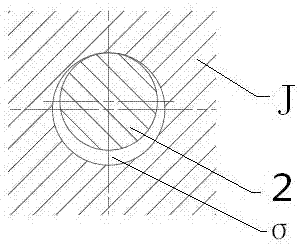

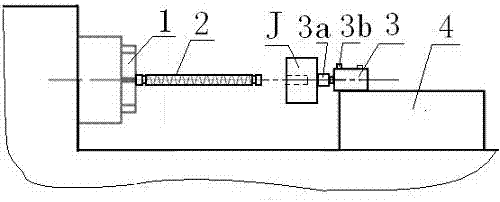

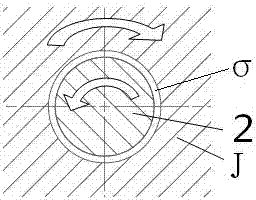

[0024] Examples of the present invention figure 2 As shown, it includes the floating grinding tool of the present invention, including lathe spindle jaw 1, grinding rod 2, floating grinding tool 3, and lathe tool rest 4; The grinding tool 3 includes a motor, a frequency converter, a magnetic rotating head 3a, and a speed control switch 3b; the lathe spindle clamp jaw 1 clamps the grinding rod 2 to rotate; the motor and the frequency converter are connected by wires, and the magnetic rotating head 3a is installed on the front end of the motor spindle; floating The grinding tool 3 is installed on the lathe tool rest 4; the lathe tool rest 4 reciprocates linearly, driving the floating grinding tool 3 to move; the height of the magnetic rotating head 3a of the floating grinding tool 3 is adjustable, and the magnetic rotating head is adjusted by the hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com