Automatic salt turning robot

A technology of automatic turning and robotics, which is used in manipulators, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

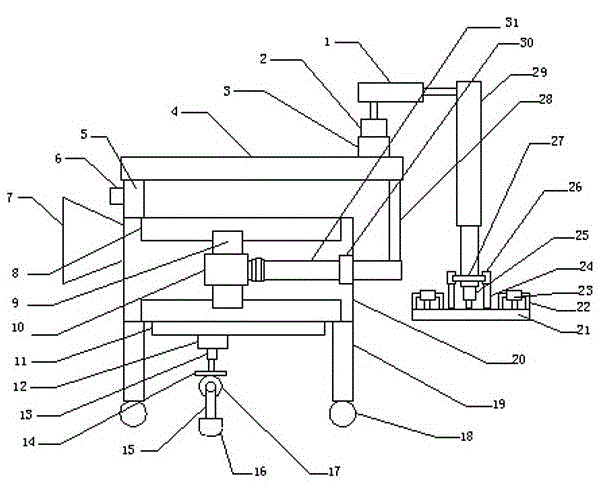

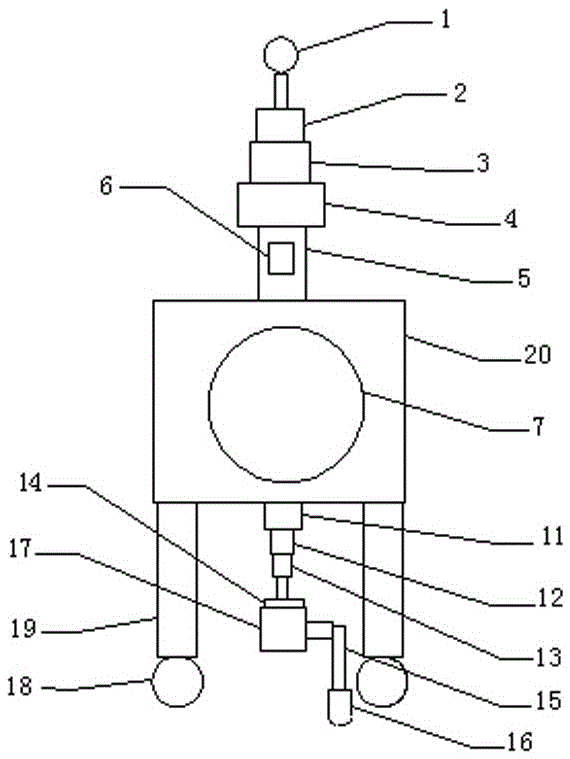

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] An automatic salt turning robot of the present invention includes a first cylinder 1, a first motor 2, a first moving block 3, a first linear motor 4, a first pillar 5, a controller 6, a propeller 7, and a first slide rail 8. The first slider 9, the third motor 10, the second linear motor 11, the second moving block 12, the third cylinder 13, the support plate 14, the pillar 15, the broom 16, the electric push rod 17, the wheel 18, the wheel frame 19. Sleeve 20, pressure plate 21, machine base 22, vibration motor 23, pole 24, second motor 25, second slider 26, second slide rail 27, second pillar 28, second cylinder 29, screw nut 30 and lead screw 31, the propeller 7 is installed on the left side of the sleeve 20, the controller 6 controls the propeller 7 to start, and pushes the sleeve 20 to move forward; the upper and lower sides of the sleeve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com