Single-screw desktop level 3D printing consuming material forming machine and control method thereof

A 3D printing and control method technology, applied in the direction of additive processing, etc., can solve the problems of 3D consumables such as moisture absorption, unsatisfactory quantity, and difficult storage, and achieve the effects of saving consumables, solving difficult storage, and improving the rigidity of the fuselage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

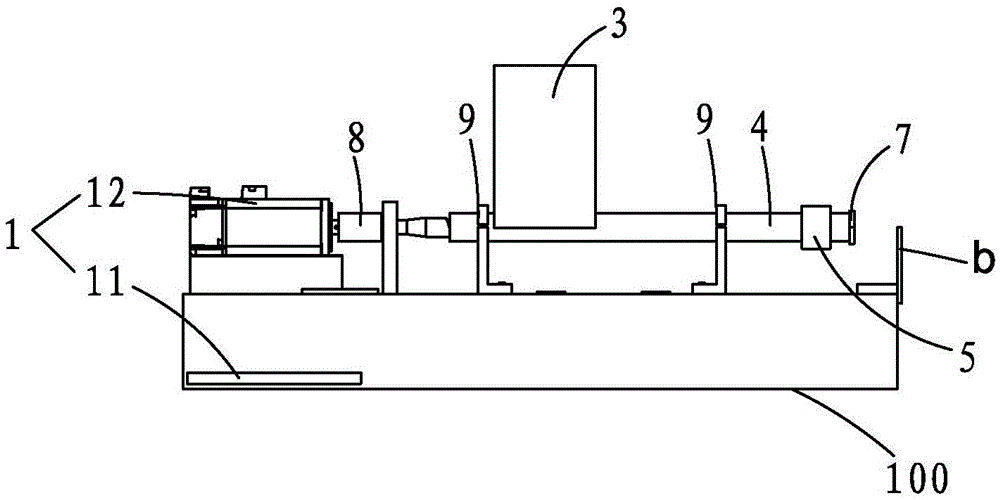

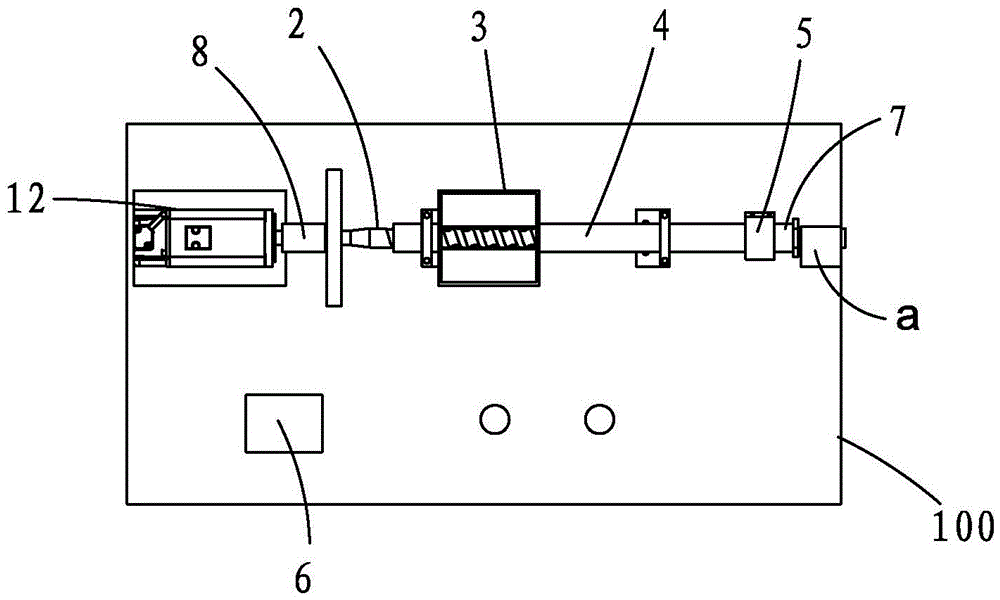

[0023] Such as figure 1 and figure 2 As shown, the single-screw desktop-level 3D printing consumable molding machine of the present invention includes a driving mechanism 1, a screw 2, a funnel 3, a barrel 4, a heater 5, a heat collector (not shown in the figure), and a thermocouple (Fig. (not shown), temperature controller 6 and nozzle 7, the driving mechanism 1 is connected to one end of the screw 2, the other end of the screw 2 passes through the end of the barrel 4, and is sleeved on the barrel. Inside the barrel 4, the barrel 4 is provided with an opening (not shown in the figure), the opening is close to the end of the barrel 4, and the screw 2 passes through the opening, and the funnel 3 is connected to the The other end of the barrel 4 is connected to the nozzle 7 through the heater 5, the heat collector is arranged on one side of the heater 5, and the thermocouple is used to collect the heat collector The temperature signal of the thermocouple is connected to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com