Conveniently assembled and maintained axle speed reducer

An axle reducer and reducer technology, which is applied to control devices, vehicle parts, transportation and packaging, etc., can solve the problems of many related parts, difficult on-site maintenance, affecting assembly quality and efficiency, etc., to simplify and improve the cooperation relationship. The effect of machining accuracy and reduction of backlash instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

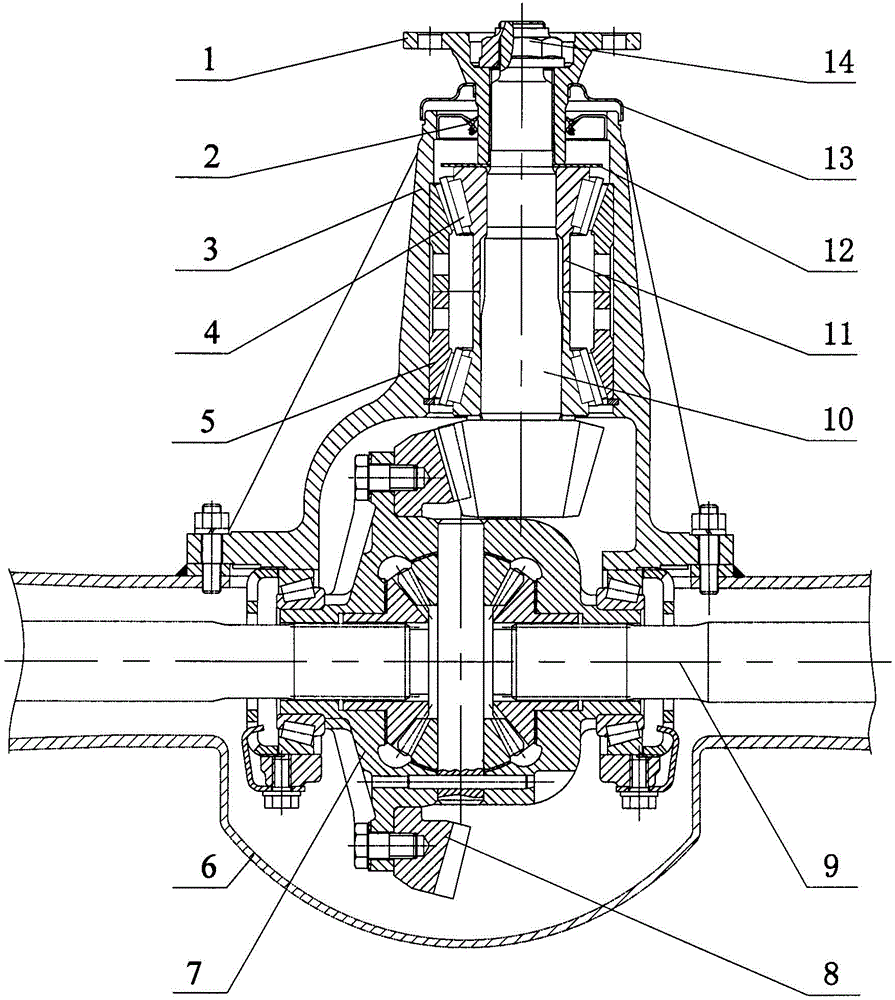

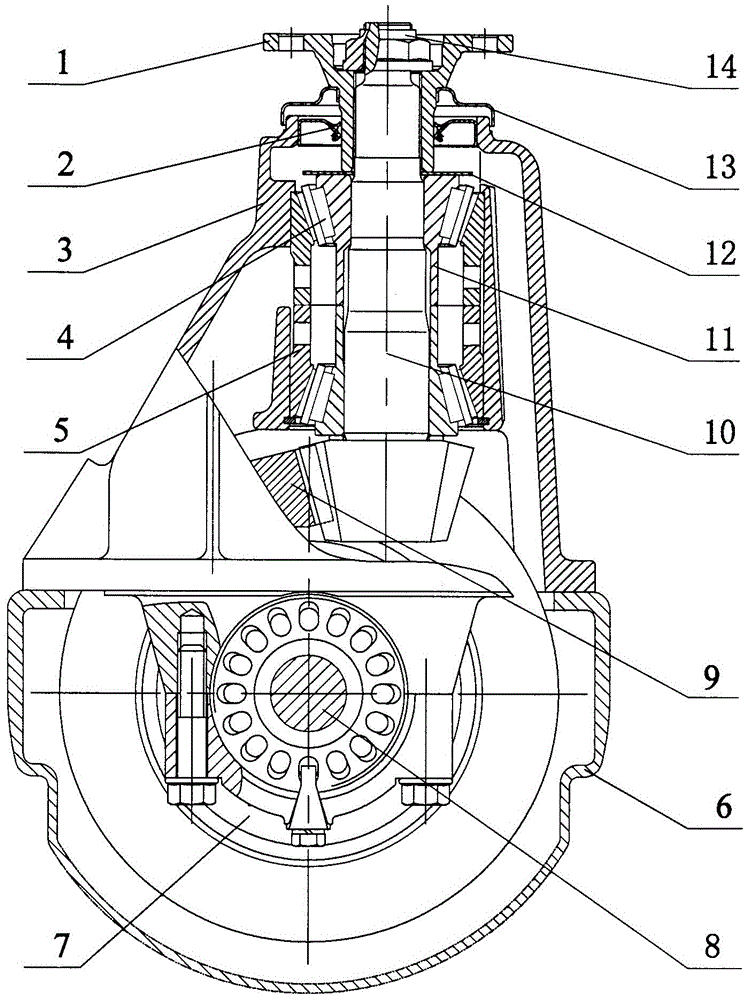

[0014] according to Figure 1~2 The specific structure of the present invention will be described in detail. The axle reducer with convenient assembly and maintenance includes a reducer housing 3, a power input shaft support structure assembled with the reducer housing 3, an axle housing 6, and a half shaft 9 assembled in the axle housing 6. , differential and the driven gear 8 etc. which are meshed with the end gear of the driving gear shaft 10. The supporting structure of the power input shaft consists of two rows of oppositely arranged bearings with the same structure as the outer ring assembled with the reducer housing 3, and the input torque flange 1 and the oil throwing ring that firmly support the bearing on the driving gear shaft 10 12, dust cover 13 and lock nut 14 etc. constitute. Each row of bearings includes an outer ring 5 with the same structure, an inner ring 11 with basically the same structure but different inner diameters, and rolling elements 4 with the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com