Reversing four-bar linkage wide-angle front-wheel steering system for large coal mine vehicle

A front-wheel steering and four-link technology, which is applied to the steering mechanism, steering rod, vehicle components, etc., can solve the problems that coal mine underground vehicles cannot meet the use requirements, and achieve the effect of novel structure, simple operation, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

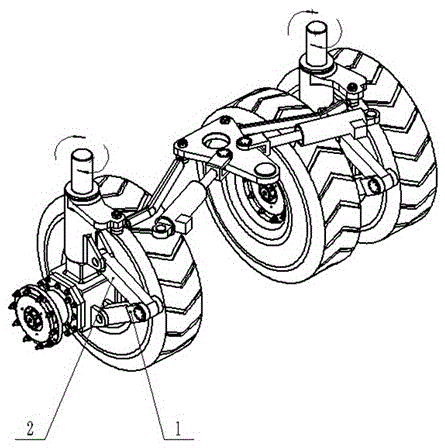

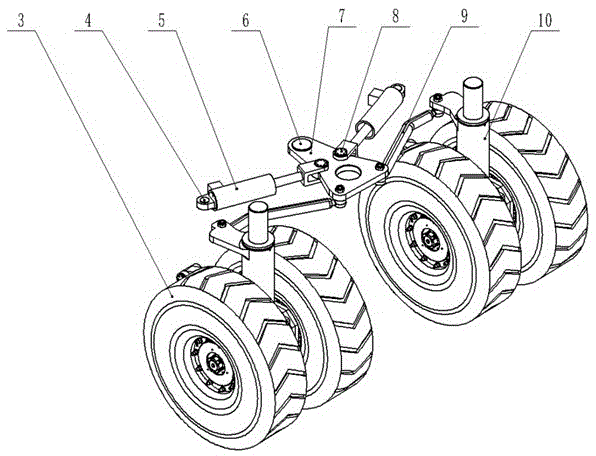

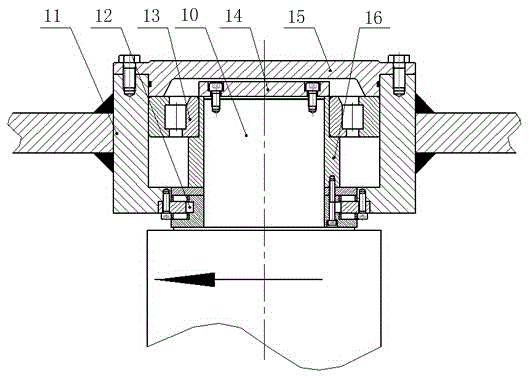

[0019] like figure 1 , 2 As shown, a reverse four-link large-angle front wheel steering system for a large coal mine vehicle includes left and right symmetrically arranged tire assemblies 3, and the tire assemblies 3 are connected and fixed to the oil-pneumatic suspension cylinder connected to the frame 11 through the axle box. 10, the piston and cylinder barrel of the oil-air suspension cylinder 10 are respectively connected with the lower torsion beam 1 and the upper torsion beam 2, the lower torsion beam 1 and the upper torsion beam 2 are hingedly connected, and the oil-air suspension cylinders 10 on the left and right sides are connected There is a reverse four-bar linkage mechanism. The reverse four-bar linkage mechanism includes a power steering cylinder 5, a steering drive arm 7 and a steering thrust rod 9. The steering drive arm 7 is connected to the left and right tire assemblies respectively through the steering thrust rod 9 hingedly connected to it. 3. Hingedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com