A bag feeding mechanism for taking bags from hanging bags

A bag feeding and rotating mechanism technology, applied in the field of machinery, can solve the problems of increasing enterprise costs, bag feeding failure, manual adjustment, etc., and achieve the effect of improving success rate and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

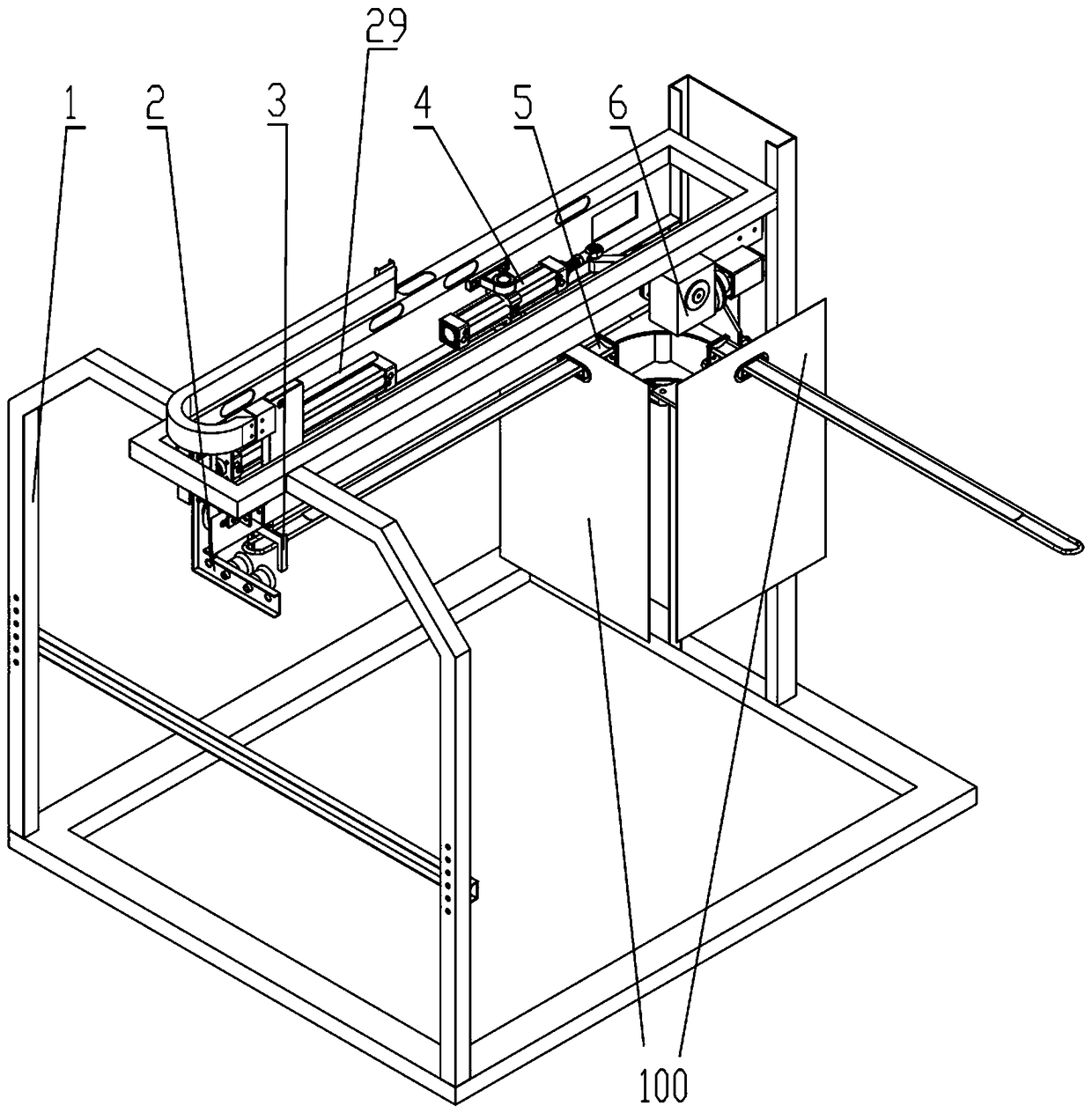

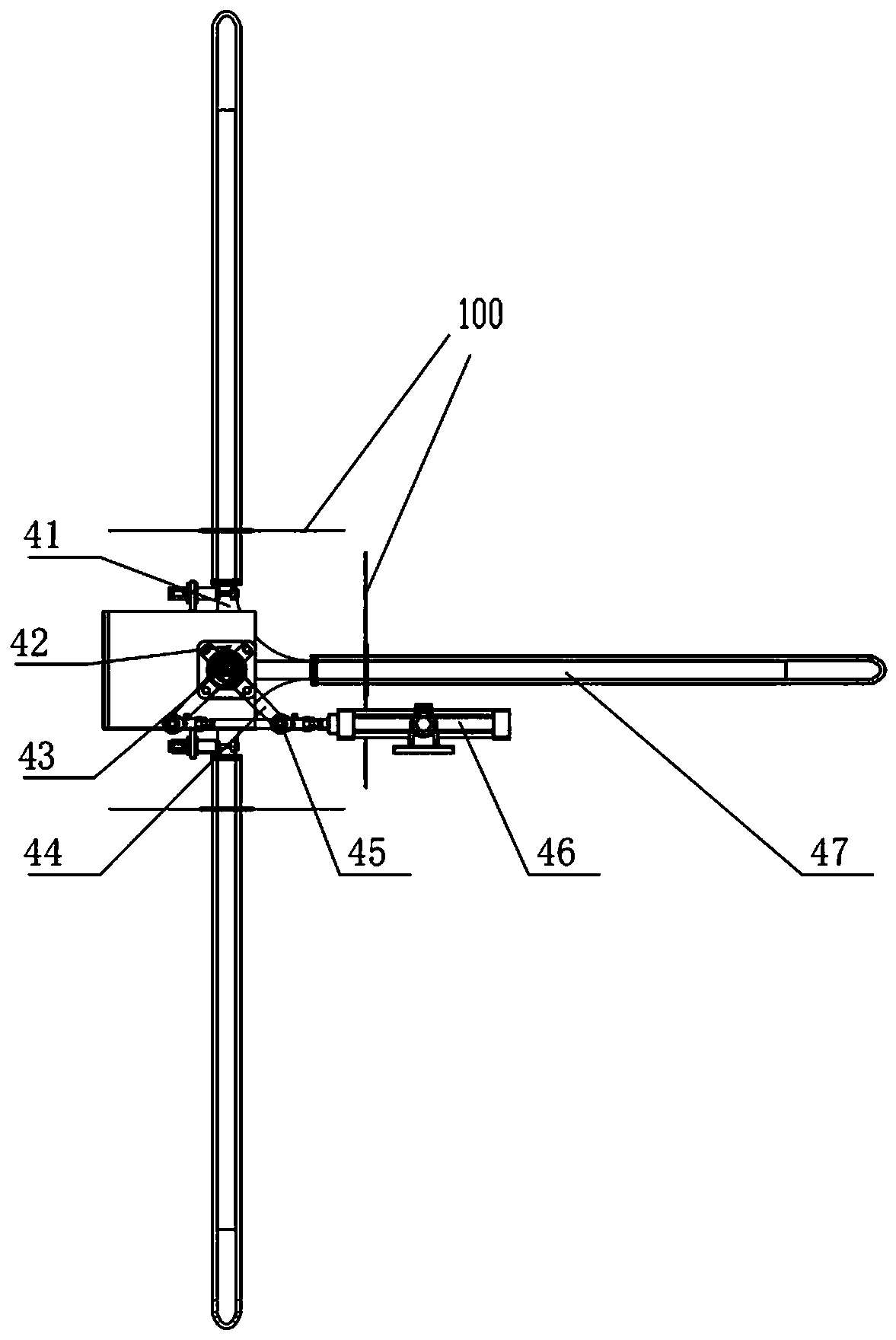

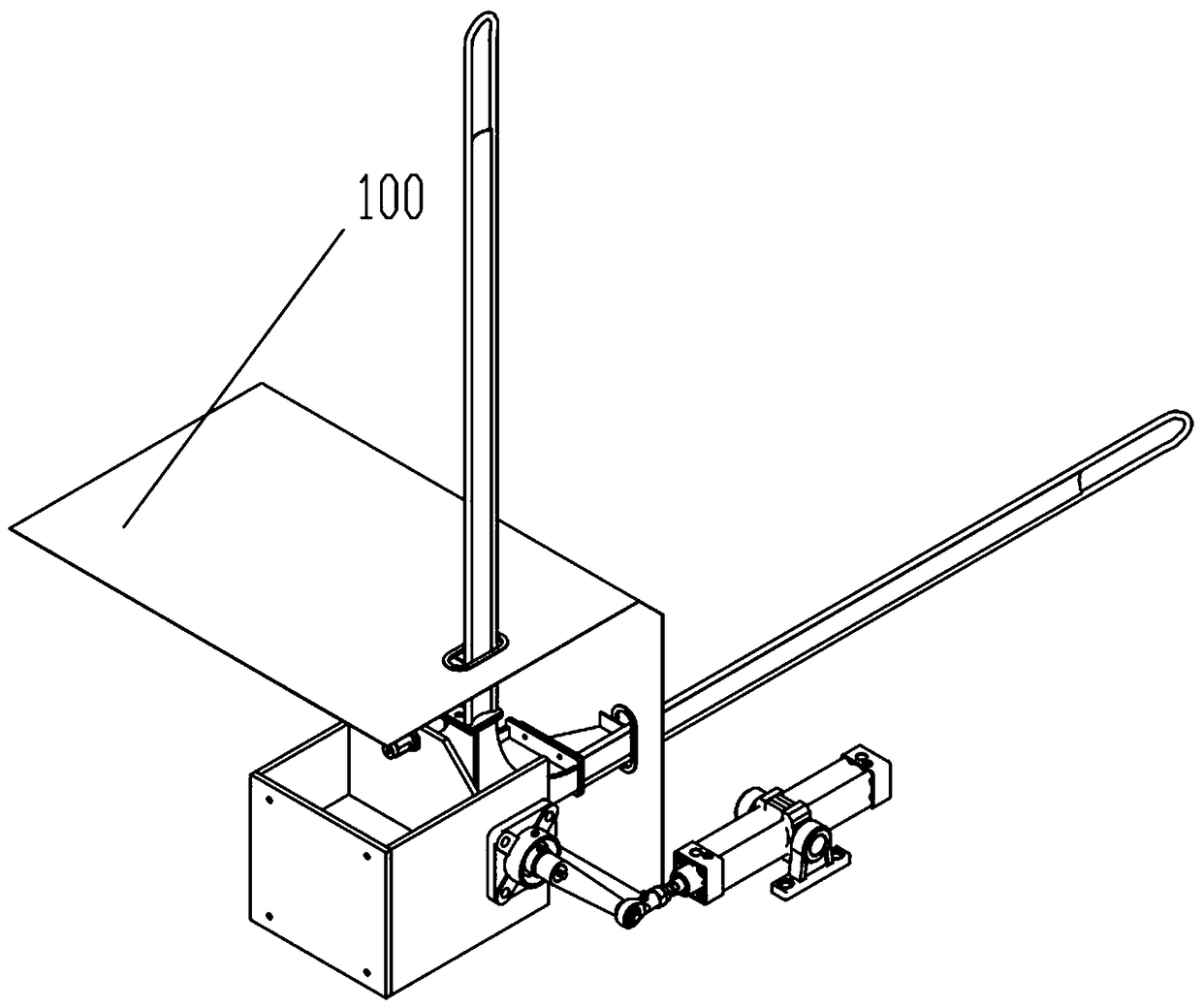

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a bag supply mechanism that takes bags from a pile of hanging bags uses a hanging method to temporarily store the handle bags and transport them to the external process. The bag supply mechanism includes PLC industrial control, bag storage base 1, bag dividing mechanism 2, Push plate rotating mechanism 3, hanging rod rotating mechanism 4, handle bag hanging rod 47 and progressively pushing bag mechanism 6; Described storage bag base 1 is provided with storage bag mechanism; Described handle bag hanging rod 47 and hanging rod rotating mechanism 4 Connected, under the drive of the hanging rod rotating mechanism 4, it swings back and forth between the bag storage mechanism and the bag-dividing mechanism 2 to carry out bag replenishment and bag pushing positioning of the hanging bag pile; Move back and forth with the bag-dividing mechanism 2, and push the handbag hanging from the hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com