A double-rotation and multi-angle adjustment remote control bin-out machine

A multi-angle, double-rotation technology, applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of unstable walking, affecting the efficiency of the warehouse, and low efficiency of the warehouse, so as to increase the scraping range and facilitate the transmission. , The effect of high warehouse delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

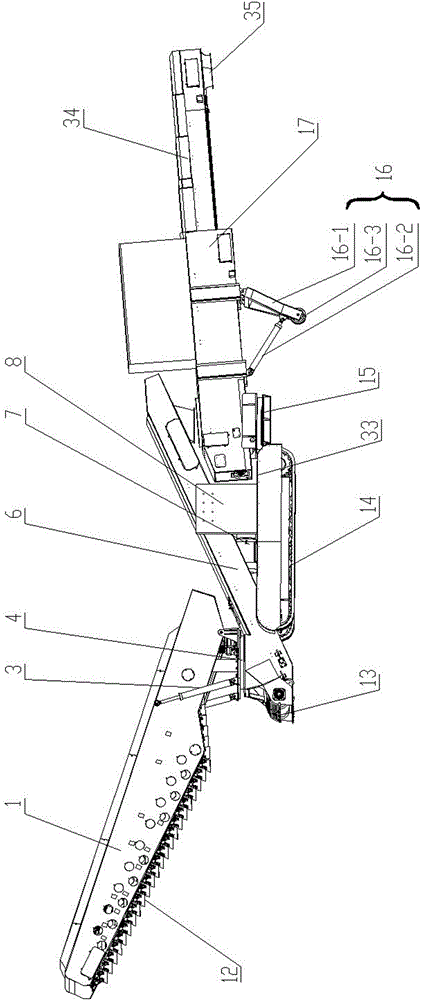

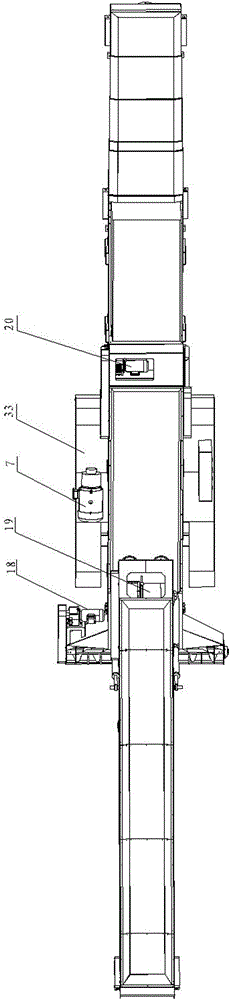

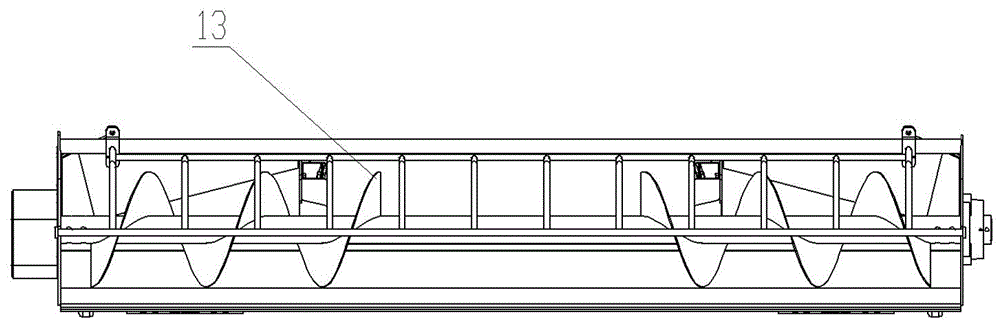

[0027] as attached Figure 1-3 As shown, a double-rotating multi-angle adjustable automatic warehouse-out machine includes a frame 33, a scraper conveyor 1 whose lower end is arranged on the frame 33 to scrape materials, and is arranged on the frame 33 to transport the materials out. The telescopic conveyor 34 of the warehouse, the inclined conveyor 6 arranged on the frame between the scraper conveyor 1 and the telescopic conveyor to transport materials obliquely, and the end of the inclined conveyor 6 located at the lower end of the scraper conveyor 1 Feeding device, during the operation of the scraper conveyor 1, its scraper 12 can scrape the material on the top of the material pile to the feeding device, which overcomes the slow flow of material or no longer freely falling to the feeding device when the slope is not enough. The problem of the feeding port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com